Method for preparing MnOOH nano rods

A nanorod, potassium permanganate technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing and other directions, can solve the problems of cumbersome operation, low solubility, no morphology of products, and achieve uniform particle size distribution, simple process, Easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

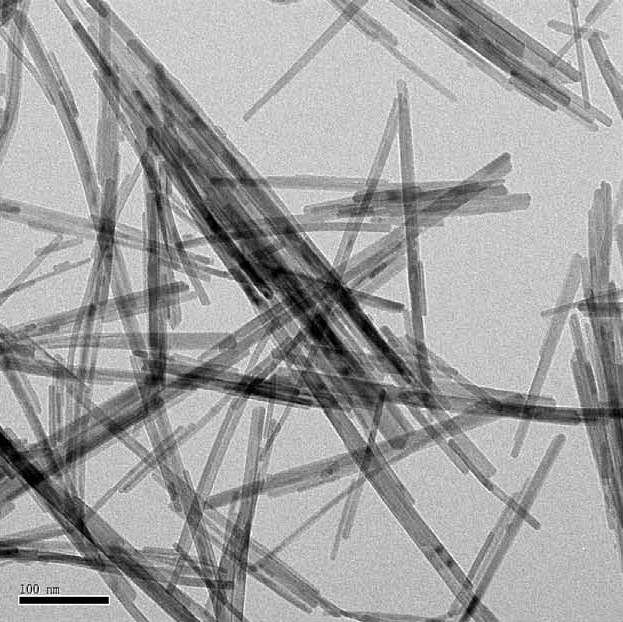

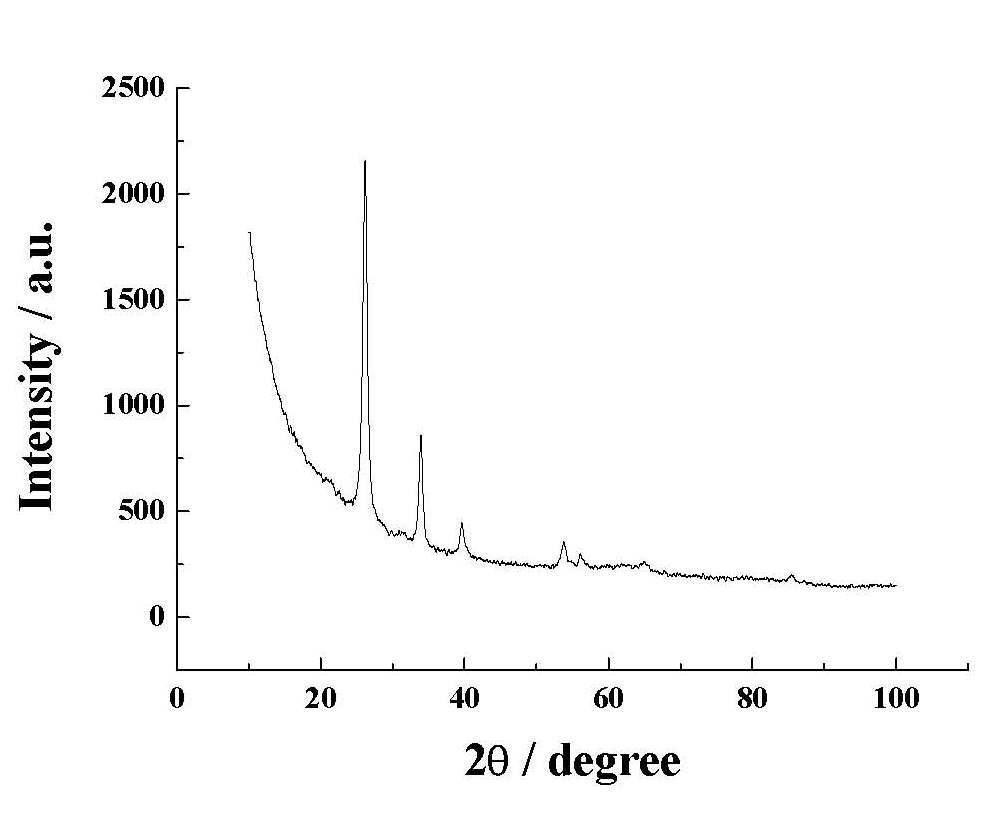

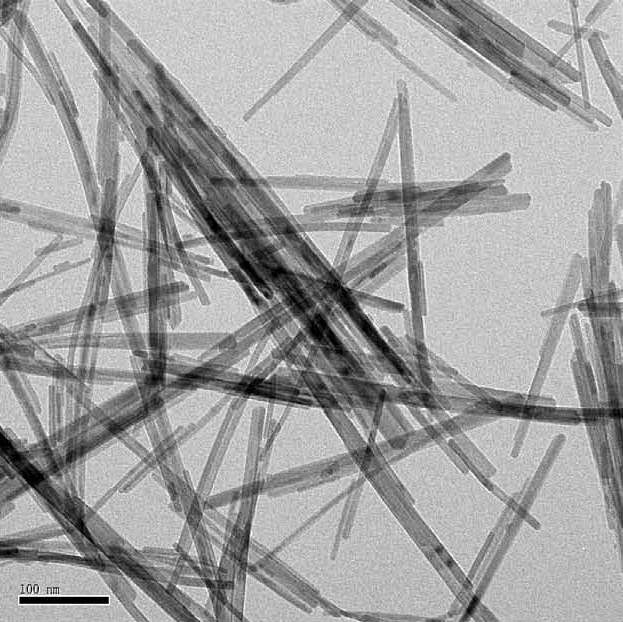

[0013] Weigh 0.2g of potassium permanganate, dissolve it in 15mL of N,N-dimethylformamide, raise the temperature of the reaction system to 120°C under airtight conditions, and control the reaction system at The solvothermal reaction was carried out at a temperature of 120°C for 10 hours. This reaction is also a redox reaction. The main product is basic manganese oxide (MnOOH), and the basic manganese oxide is solid, and the rest of the products are dissolved in the liquid system. The reacted mixture is subjected to solid-liquid separation by centrifugation or filtration to remove liquid substances and leave solid basic manganese oxide, and then wash the solids with distilled water and absolute ethanol in sequence, and finally wash the solids at a temperature of 80°C The washed solid is vacuum-dried for 2-3 hours, and the air pressure in the drying oven is 0.01-0.03 MPa to obtain MnOOH nanorods with a diameter of 8nm-12nm and a length of 50nm-500nm.

Embodiment 2~ Embodiment 5)

[0015] Each embodiment is basically the same as Embodiment 1, and the differences are shown in Table 1.

[0016] Table 1

[0017]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com