Method for measuring impurity content of faropenem polymers in faropenem sodium raw materials and preparations

A technology of faropenem sodium and polymers, applied in the field of pharmaceutical analysis, to achieve the effect of ensuring product quality, good repeatability, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

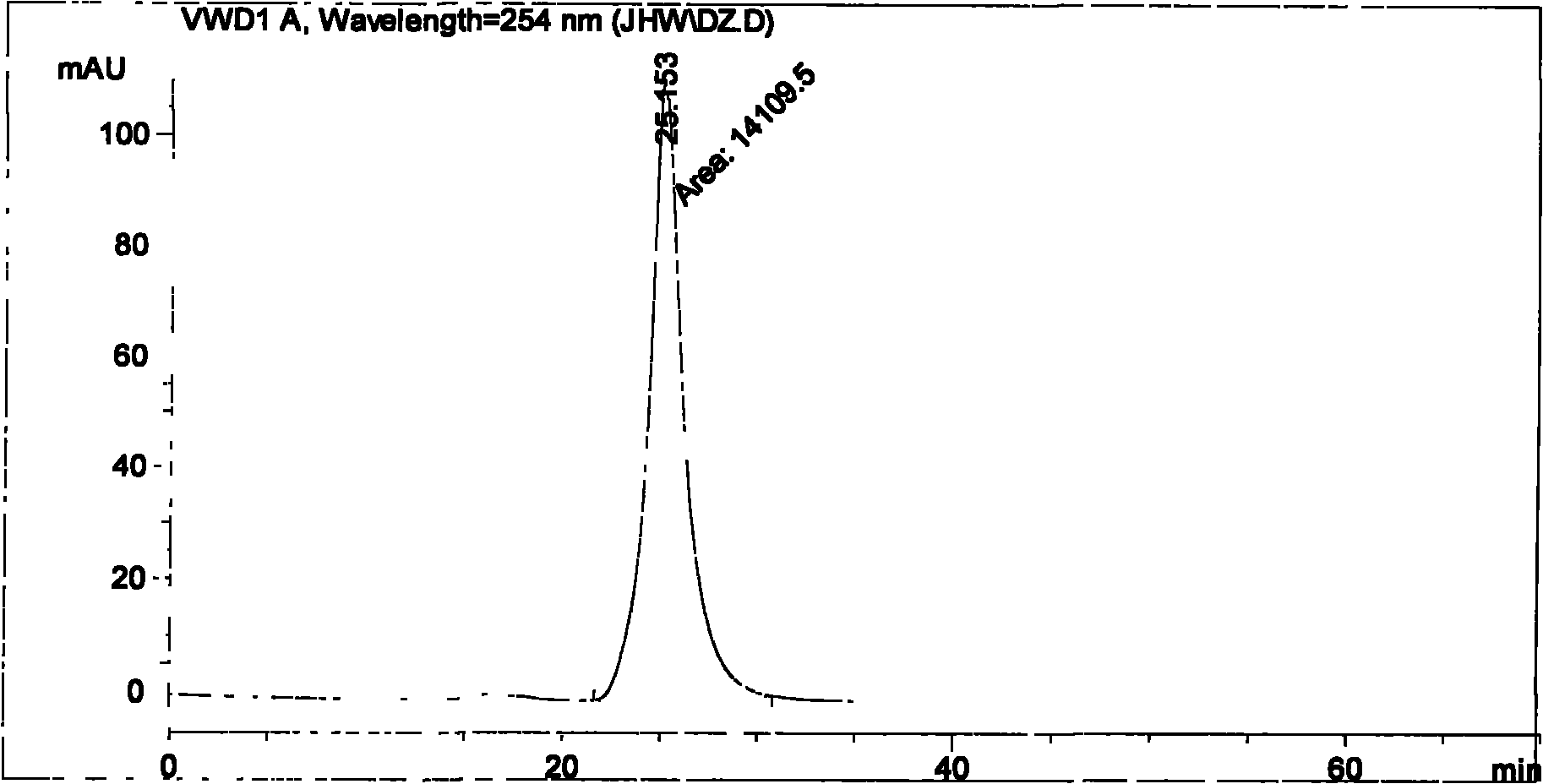

[0030] Example 1: Determination of Faropenem Polymer Content in Faropenem Sodium Raw Materials and Its Preparations by Standard Curve Method

[0031] 1. Chromatographic conditions

[0032] Instrument: American Agilent 1100 series high performance liquid chromatography;

[0033] Gel chromatography column: Sephadex G-10, 15.0mm×400mm;

[0034] Mobile Phase: Mobile Phase A: NaH 2 PO 4 1.08g and Na 2 HPO 4 4.38g to 1000ml water, with H 3 PO 4 Adjust the pH to 7.0;

[0035] Mobile Phase B: 0.01% Sodium Lauryl Sulfate

[0036] Flow rate: 1.0ml / min

[0037] Column temperature: room temperature;

[0038] Wavelength: 254nm

[0039] 2. Experimental steps:

[0040] 1. Make a standard curve:

[0041] ① Put 62.5mg of faropenem reference substance in a 50ml volumetric flask, dilute it with water to 0.05, 0.10, 0.15, 0.20, 0.25, 0.30 and 0.4mg / ml solutions, and shake well;

[0042] ②Take 20ul of the reference substance solution at each dilution point and pass through the gel colu...

Embodiment 2

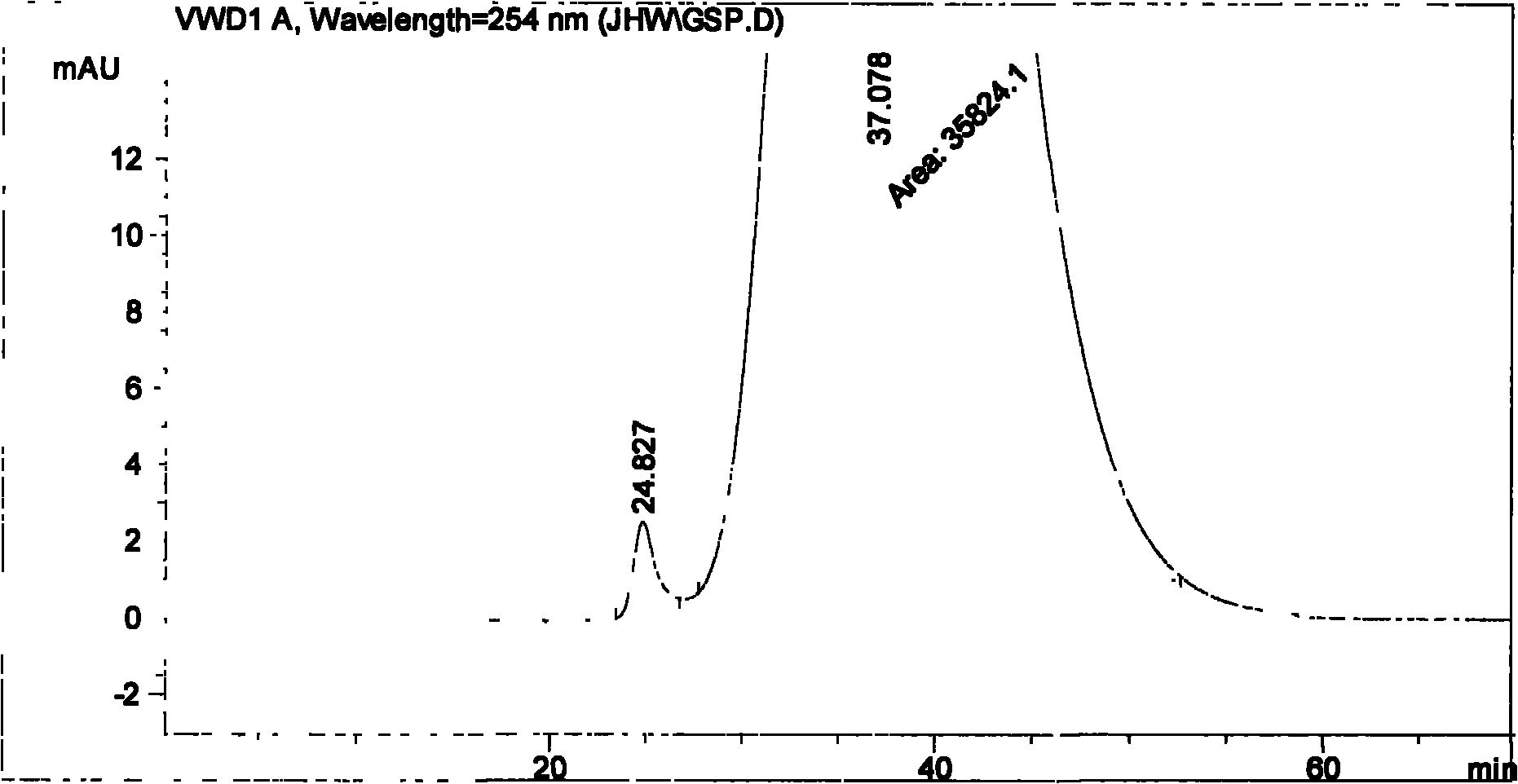

[0049] Example 2: Determination of Faropenem Polymer Content in Faropenem Sodium Raw Materials and Its Preparations by Standard Curve Method

[0050] 1. Chromatographic conditions

[0051] Same as Example 1

[0052] 2. Experimental steps:

[0053] 1. Make a standard curve:

[0054] ① Put 62.5mg of faropenem reference substance in a 50ml volumetric flask, dilute it with water to 0.05, 0.10, 0.15, 0.20, 0.25, 0.30 and 0.4mg / ml solutions, and shake well;

[0055] ②Take 20ul of the reference substance solution at each dilution point and pass through the gel column in turn, use mobile phase B as the mobile phase, detect at a wavelength of 254nm, record the chromatogram, obtain the retained peak area, and compare the peak area (A) with the concentration (C) Perform linear regression to obtain the standard curve and linear equation, and calculate the regression coefficient;

[0056] ③The regression equation obtained through calculation is: C=57203A+76.287R 2 =0.9999

[0057] 3....

Embodiment 3

[0063] Example 3: Determination of Faropenem Polymer Content in Faropenem Sodium Raw Materials and Its Preparations by Standard Curve Method

[0064] 1. Chromatographic conditions

[0065] Instrument: American Agilent 1100 series high performance liquid chromatography;

[0066] Gel chromatography column: Sephadex G-10, 15.0mm×400mm;

[0067] Mobile phase: mobile phase A: take NH 4 Cl 0.54g to 1000ml water, adjust pH to 7.0 with NaOH

[0068] Mobile Phase B: 0.01% Sodium Lauryl Sulfate

[0069] Flow rate: 1.0ml / min

[0070] Column temperature: room temperature;

[0071] Wavelength: 254nm

[0072] Two, experimental procedure is with embodiment 1

[0073] 3. Results

[0074] According to the standard curve method, the content of ropenem polymer was calculated as 0.25%. The RSD value is 0.06%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com