CO2 separation-liquefaction-purification system and method

A purification method and separation rate technology, which is applied in the field of CO2 separation-liquefaction-purification system, can solve the problems of unguaranteed separation and high energy consumption of separation, and achieve the effects of low cost, low recovery energy consumption and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

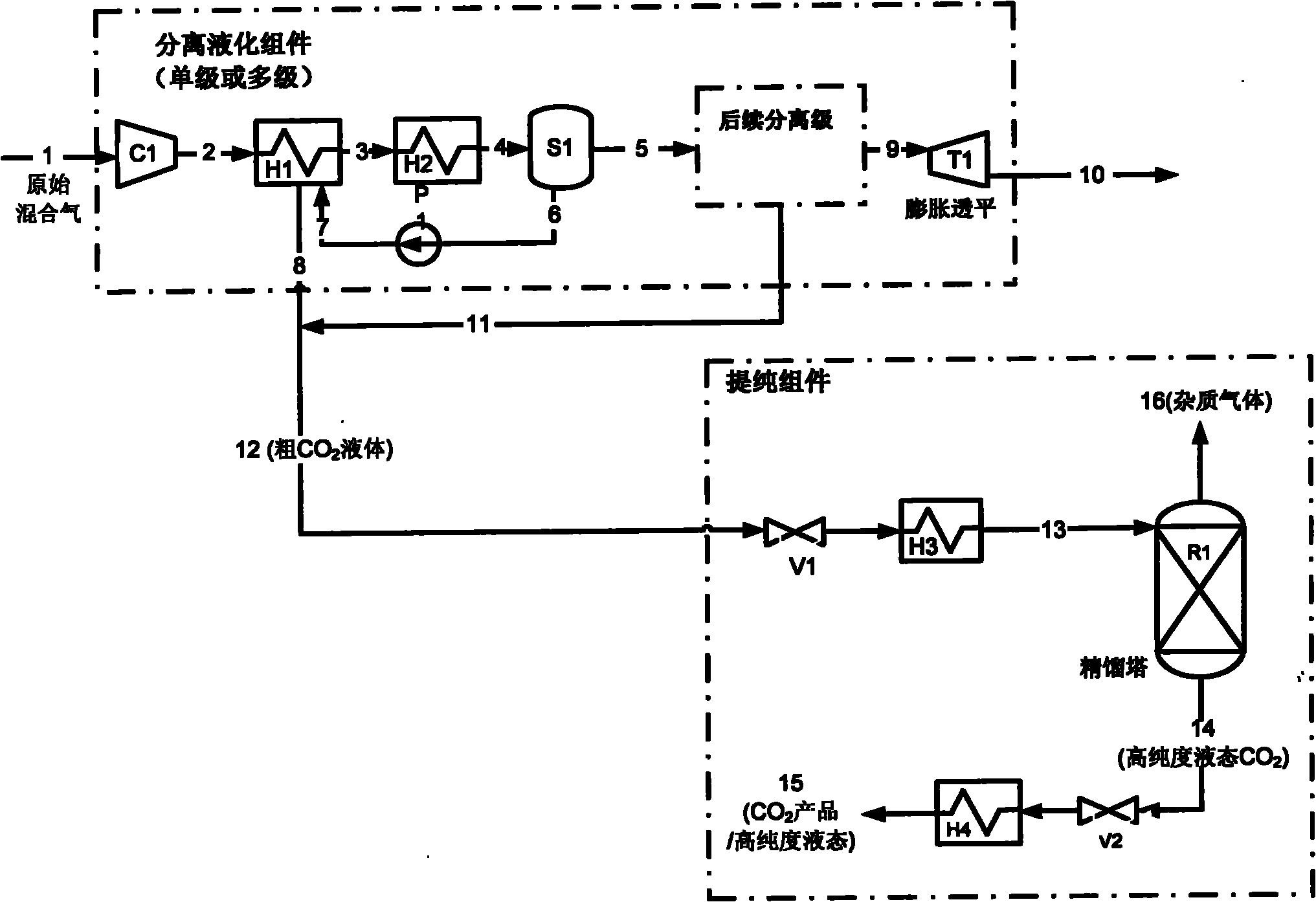

Method used

Image

Examples

Embodiment 1

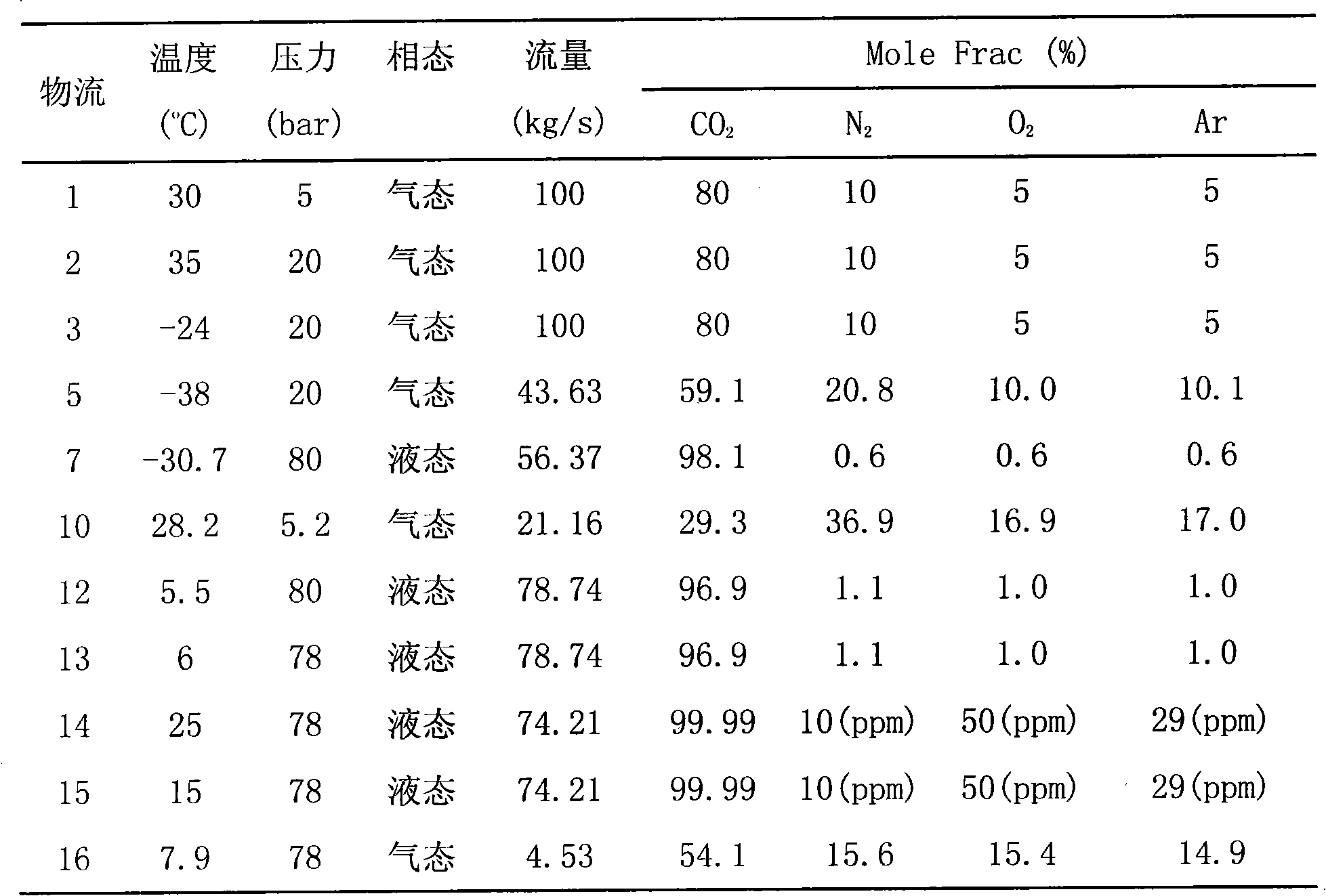

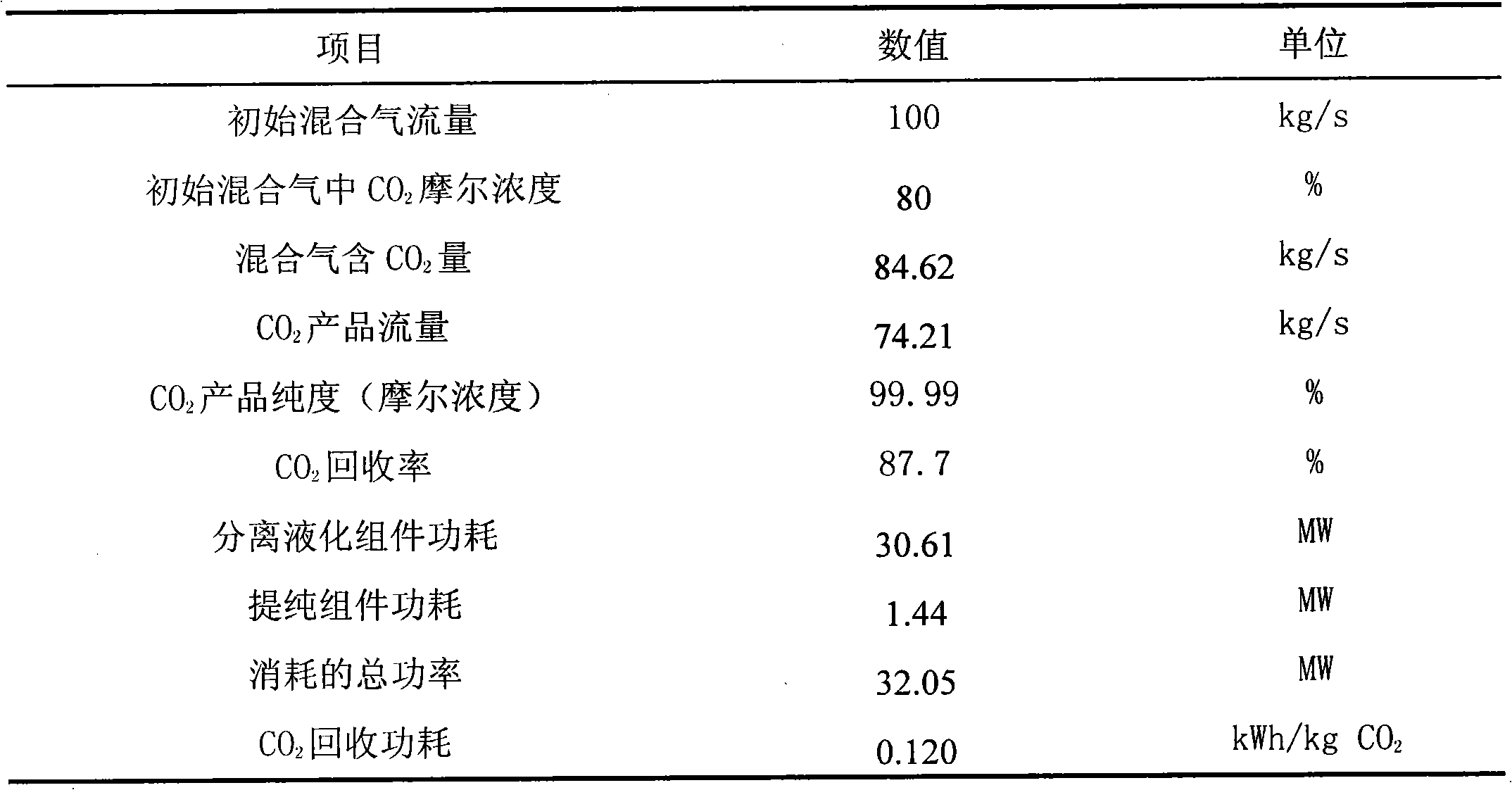

[0041] Select with CO 2 and N 2 , O 2 , Ar were 80%, 10%, 5%, 5% of the mixed gas as the research object, the analysis of CO 2 The characteristics of material flow and energy consumption when the separation-liquefaction-purification system separates it. The gas composition is similar to the flue gas composition of the combustion products under high-purity oxygen-enriched conditions using coal as fuel.

[0042]In the calculation, the compressor efficiency is taken as 0.8, the expansion turbine efficiency is 0.85, and the pump efficiency is 0.8. >5°C; minimum heat transfer temperature difference: general heat exchanger, pre-thermostat and post-set thermostat >8°C; low-temperature heat exchanger >2°C. The system is divided into two parts, the separation and liquefaction component and the purification component. The separation and liquefaction component adopts three-stage separation and liquefaction, that is, three sets of separation and liquefaction equipment are required.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com