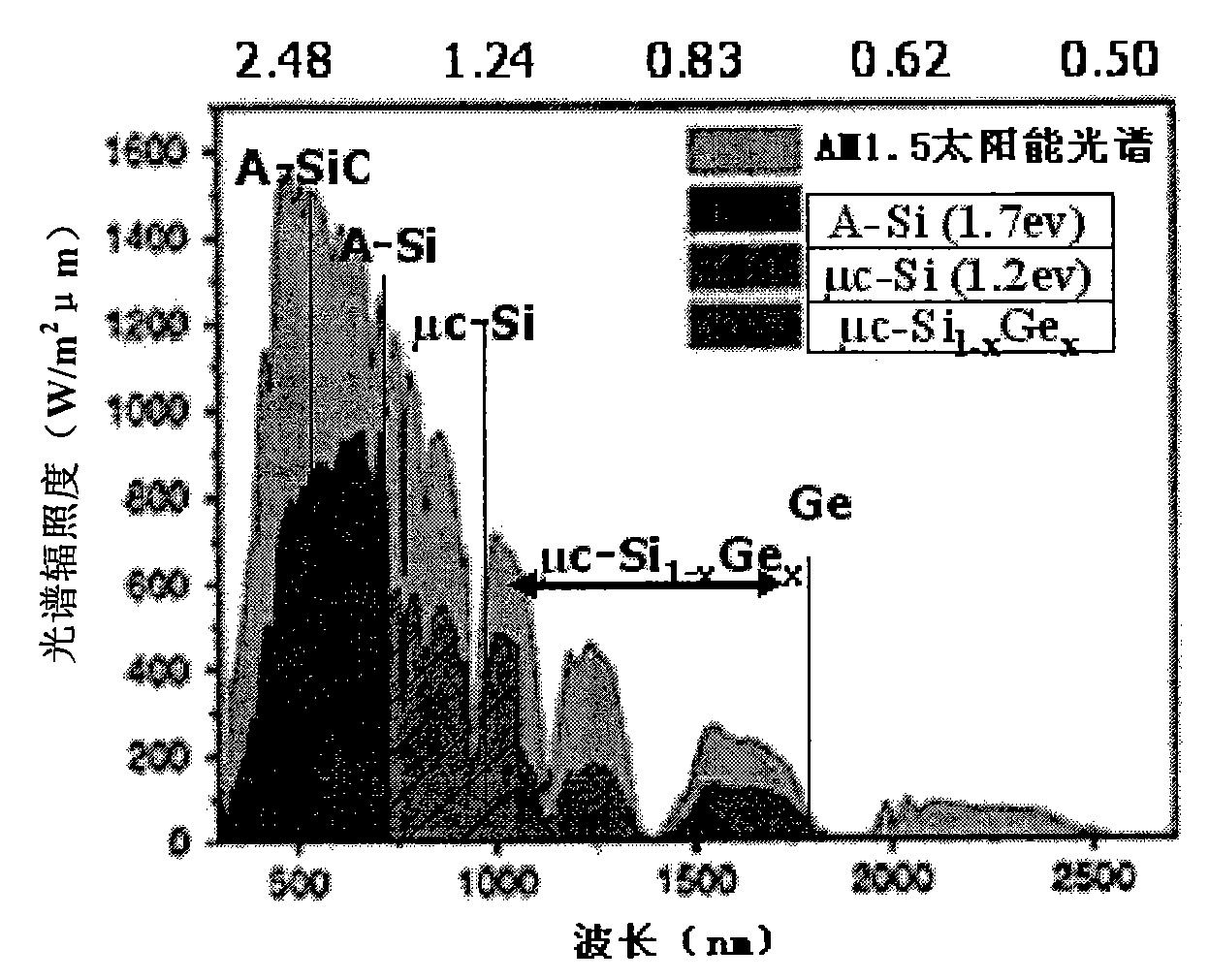

Silicon-based multijunction multi-laminated PIN thin film solar cell with high conversion rate and production method thereof

A solar cell and high conversion rate technology, applied in the field of solar cells, can solve the problems of low solar conversion efficiency and silicon-based thin-film solar cell conversion rate to be improved, achieve high photoelectric conversion efficiency, increase light absorption efficiency, and improve conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

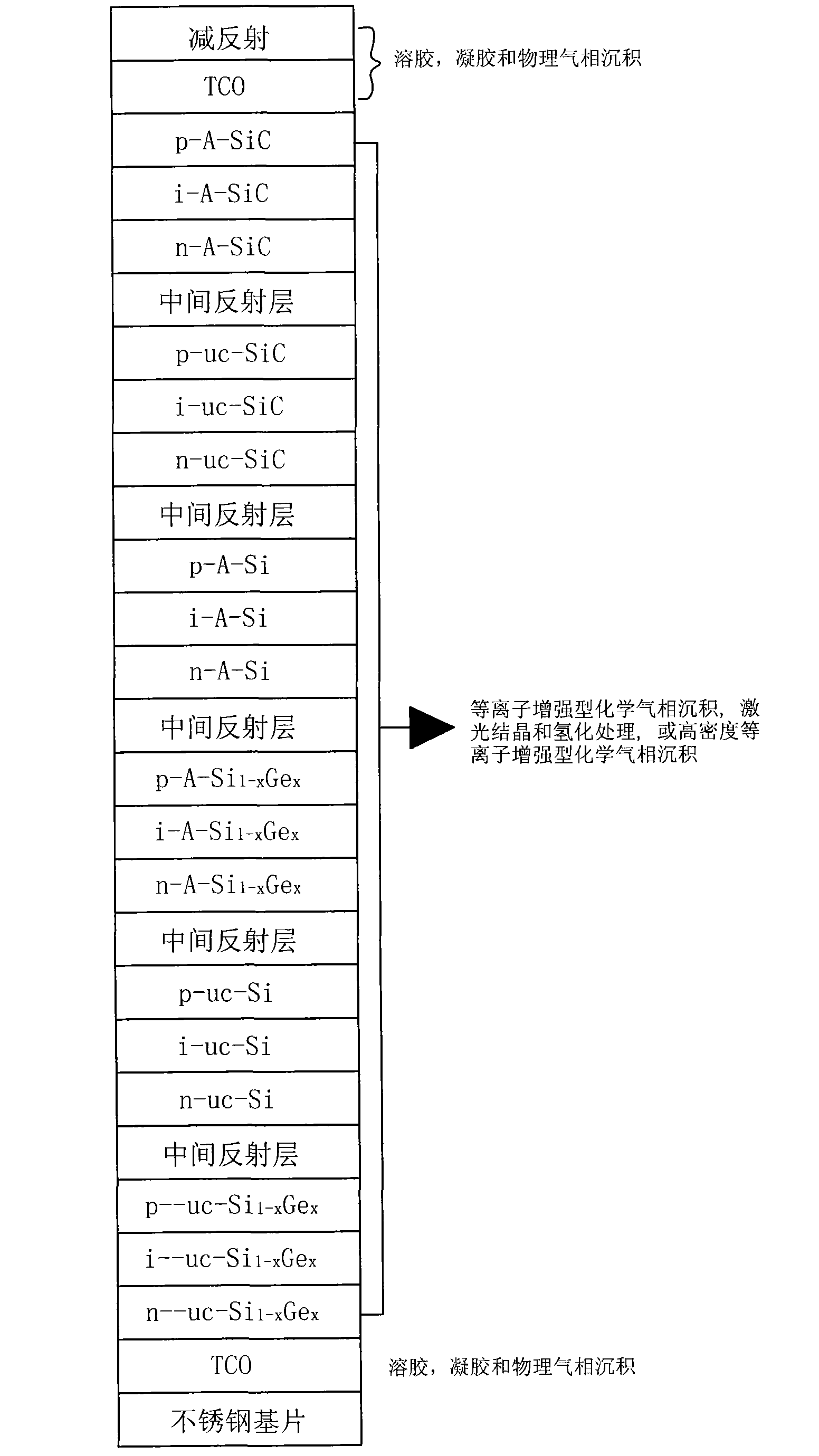

[0063] Example 1: Thin-film solar cell with multi-junction and multi-stack structure based on stainless steel

[0064] (1) Battery structure: stainless steel / TCO / n-μc-Si 1-x Ge x / i-μc-Si 1-x Ge x / p-μc-Si 1-x Ge x / intermediate reflective layer / n-μc-Si / i-μc-Si / p-μc-Si / intermediate reflective layer / n-A-Si 1-x Ge x / i-A-Si 1- x Ge x / p-A-Si 1-x Ge x / intermediate reflective layer / n-A-Si / i-A-Si / p-A-Si / intermediate reflective layer / n-μc-SiC / i-μc-SiC / p-μc-SiC / intermediate reflective layer / n-A-SiC / i-A-SiC / p-A-SiC / TCO / anti-reflection coating;

[0065] (2) Preparation process:

[0066] 1. After cleaning the stainless steel sheet, use PVD method to prepare ZnO:Ag, Al thin film (or use sol-gel method), then dry it, and then heat treatment at 400 ° C for 1 minute to 10 minutes in a hydrogen-containing atmosphere;

[0067] 2. Deposition of phosphorus (P) doped amorphous A-Si by PECVD method 1-x Ge x Thin film (1>x>0 uniform transition), then laser crystallization to form...

Embodiment 2

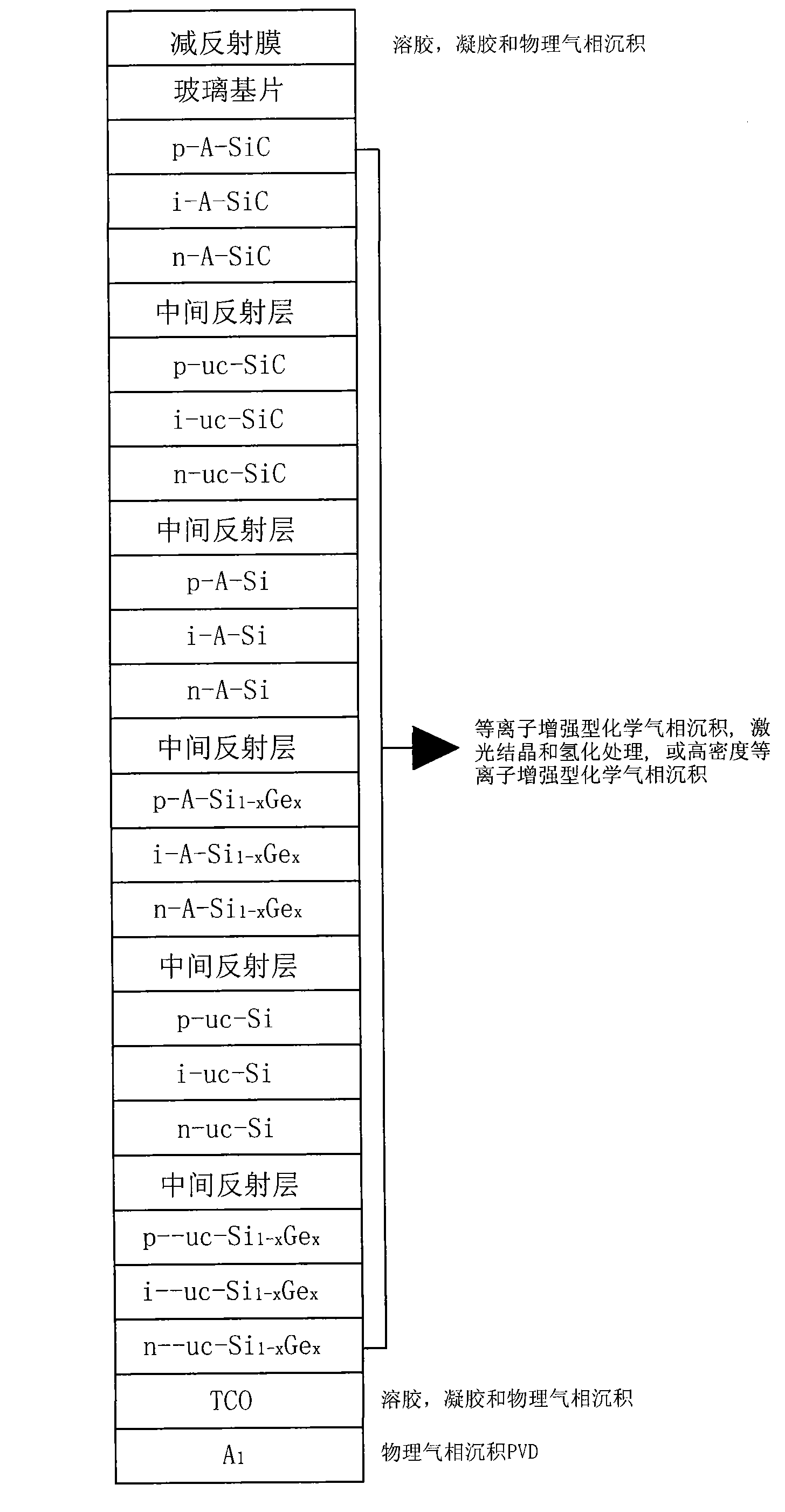

[0087] Example 2: Thin-film solar cell with glass substrate multi-junction multi-layer structure

[0088] (1) Battery structure: anti-reflection film / glass / TCO / p-A-SiC / i-A-SiC / n-A-SiC / intermediate reflection layer / p-μc-SiC / i-μc-SiC / n-μc-SiC / intermediate reflection layer / p-A-Si / i-A-Si / n-A-Si / intermediate reflection layer / p-A-Si 1-x Ge x / i-A-Si 1-x Ge x / n-A-Si 1-x Ge x / intermediate reflective layer / p-μc-Si / i-μc-Si / n-μc-Si / intermediate reflective layer / p-μc-Si 1-x Ge x / i-μc-Si 1-x Ge x / n-μc-Si 1- x Ge x / TCO / Al;

[0089] (2) The preparation process is as follows:

[0090] 1. After cleaning the glass sheet, use PVD method to prepare ZnO:Ag, Al thin film (or prepare it by sol-gel method), then dry it, and then heat treat it at 400°C for 1 minute to 10 minutes in a hydrogen-containing atmosphere;

[0091] 2. Deposit p-type boron (B)-doped amorphous A-SiC, i-type amorphous A-SiC, phosphorus (P)-doped n-type amorphous A-SiC films by PECVD method or HD-PECVD method , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com