Processing method of electroplating wastewater containing cyanogens and chrome

A treatment method and technology for electroplating wastewater, applied in metallurgical wastewater treatment, neutralized water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of unpublished concentrated water treatment method, unsuitable treatment, high energy consumption, etc., to achieve Significant energy saving effect, simplified concentrated water treatment process, and reduced treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

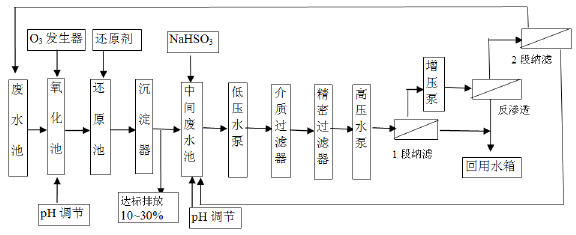

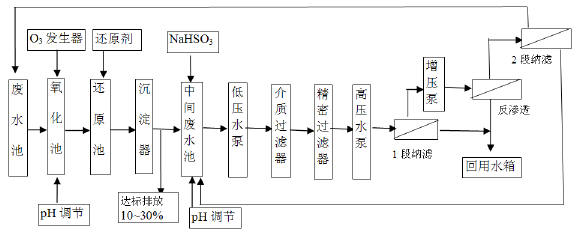

[0026] A mixed electroplating wastewater containing cyanide and chromium has a pH value of 7.5, wherein the total cyanide content is 21.8 mg / L, the hexavalent chromium content is 27.5 mg / L, and the total heavy metal ion content such as copper and zinc is less than 100 mg / L. using as figure 1 The method shown:

[0027] (1) Adjust the pH of electroplating wastewater to 8.5 with 20% NaOH solution;

[0028] (2) Start O 3 generator, press O 3 :CN - The mass ratio is 4:1 into O 3 , stir, control the oxidation time to be 45 minutes (min) and then enter the reduction tank;

[0029] (3) Press hydrazine hydrate (N 2 H 2 ·H 2 O) The mass ratio to hexavalent chromium is 0.75:1, add the reducing agent hydrazine hydrate into the reduction tank, stir, and the wastewater is sent to the precipitator for solid-liquid separation after the reduction time in the reduction tank is 30min;

[0030] (4) The clear liquid after precipitation meets the comprehensive sewage discharge standard (GB...

Embodiment 2

[0039] A mixed electroplating wastewater containing cyanide and chromium, the pH value is 8.8, the total cyanide content is 31.5mg / L, the hexavalent chromium content is 37.8mg / L, and the total heavy metal ion content such as copper and zinc is 100-200mg / L . Since the pH value of electroplating wastewater is 8.8, there is no need to adjust the pH value. The specific treatment steps are as follows:

[0040] (1) Start O 3 generator, press O 3 :CN - (mass ratio) 5:1 into O 3 , stir, and control the oxidation time to enter the reduction tank after 60min;

[0041] (3) Press hydrazine hydrate (N 2 H 2 ·H 2 O) with a mass ratio of hexavalent chromium of 1:1, add reducing agent hydrazine hydrate to the reduction tank, stir, and the wastewater is sent to the precipitator for solid-liquid separation after the reduction time in the reduction tank is 60min;

[0042] (4) The clear liquid after precipitation reaches the comprehensive sewage discharge standard (GB8978-1996), of which ...

Embodiment 3

[0051] A mixed electroplating wastewater containing cyanide and chromium, with a pH value of 9.2, wherein the total cyanide content is 51.3 mg / L, the hexavalent chromium content is 62.8 mg / L, and the total copper, total zinc, total chromium and other total heavy metal ions content are More than 200mg / L. Since the pH value of electroplating wastewater is 9.2, there is no need to adjust the pH value. The specific treatment steps are as follows:

[0052] (1) Start O 3 generator, press O 3 :CN - (mass ratio) 6:1 into O 3 , stir, and control the oxidation time to enter the reduction tank after 60min;

[0053] (3) Press hydrazine hydrate (N 2 H 2 ·H 2 O) with a mass ratio of hexavalent chromium of 1:1, add reducing agent hydrazine hydrate to the reduction tank, stir, and the wastewater is sent to the precipitator for solid-liquid separation after the reduction time in the reduction tank is 60min;

[0054] (4) The clear liquid after precipitation meets the comprehensive sewag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com