Method for preparing biodegradable spherical porous starch foam and application

A porous starch and biological technology, applied in the field of pharmacy, can solve the problems of unseen and improve the water solubility of insoluble drugs, and achieve the effects of low production cost, improved specific surface area and dispersibility, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

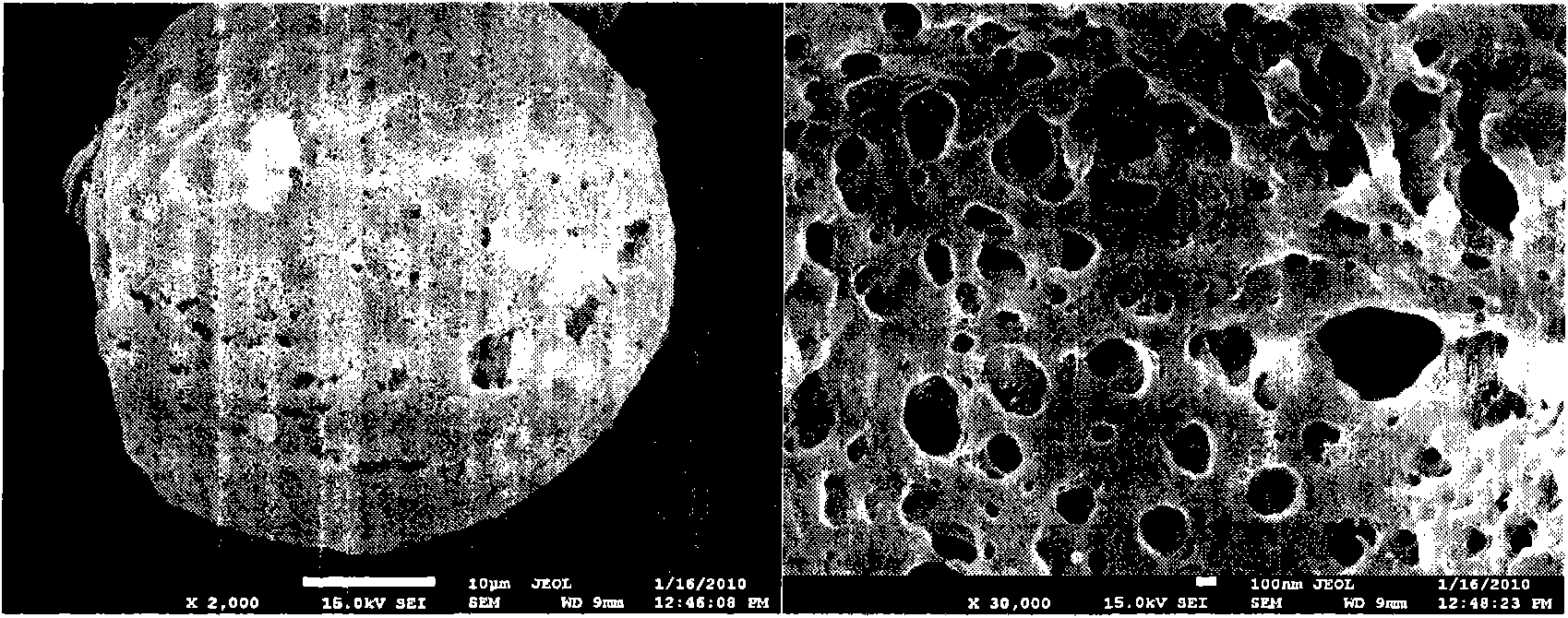

Embodiment 1

[0042] Weigh 1.25g, 1.6g, and 2g of soluble starch in a 25ml beaker, add 20ml of water to make the concentration of the aqueous starch solution 6%, 8%, and 10%, stir, put in a boiling water bath for 20min, and place it at 80°C as the water phase. Toluene: chloroform (3:1) is the oil phase, Span80 is the emulsifier, mix the water phase and the oil phase (1:20), stir or homogenize at high speed to form a uniform W / O emulsion, and put it in a -20°C refrigerator Freeze and stratify, add 40% ethanol to separate and remove the organic layer, and the obtained aqueous phase is equilibrated for 6 hours and then equilibrated with 60% ethanol for suction filtration, and then followed the previous steps to equilibrate with 80% and 100% ethanol to remove the gel beads. Water, form the alcohol gel pellet of porous structure, after suction filtration, the product is put in the vacuum desiccator and dried 24h.

Embodiment 2

[0044] Weigh 1.25g, 1.6g, and 2g of pressed rice starch into a 25ml beaker, add 20ml of water to make the concentration of the aqueous starch solution 6%, 8%, and 10%, stir, stir, put in a boiling water bath for 20 minutes, and place at 80°C as water phase, using toluene: chloroform (3:1) as the oil phase, Span80 as the emulsifier, mixing the water phase with the oil phase (1:20), stirring or homogenizing at a high speed to form a uniform W / O emulsion, and adding- Refrigerate and stratify at 20°C, add 40% ethanol to separate and remove the organic layer, and balance the obtained aqueous phase with 60% ethanol for 6 hours, then balance with 80% and 100% ethanol according to the previous steps to remove gel particles. The water in the ball forms the alcohol gel pellet of porous structure, after suction filtration, the product is put in vacuum desiccator and dried 24h.

Embodiment 3

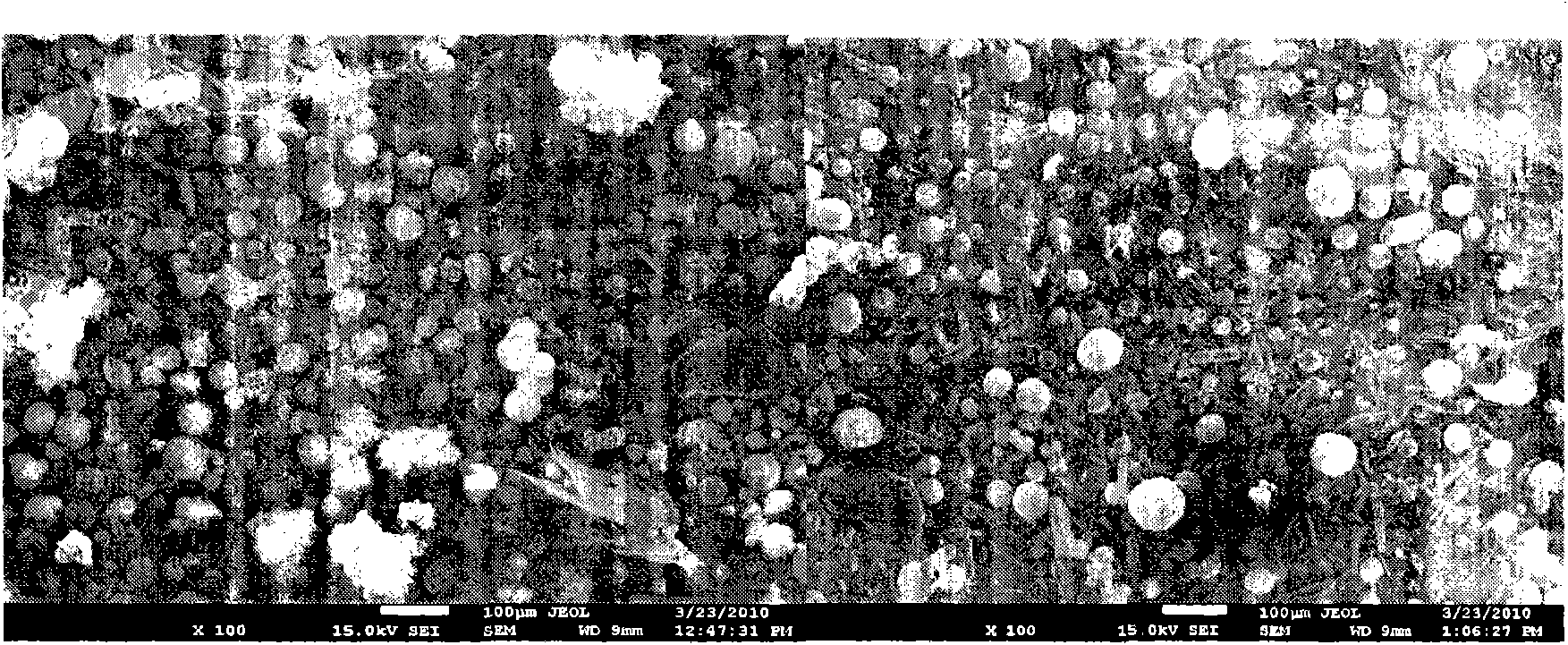

[0046] Drug loading by dipping and volatilization method

[0047] The biodegradable spherical porous starch foam is prepared and passed through an 80-mesh sieve. About 400 mg of the model drug (lovastatin) was accurately weighed and dissolved in 20 ml of chloroform to obtain a chloroform solution of the drug. Weigh 0.06, 0.18, 0.3g of biodegradable spherical porous starch foam respectively, add 3ml of drug chloroform solution respectively, so that the ratio of drug: carrier is 1:1, 1:3, 1:5 respectively, stir and mix, equilibrate for 12h, reduce Volatilize the organic solvent under pressure and dry in vacuum to obtain the drug-loaded biodegradable spherical porous starch foam drug delivery system.

[0048] Carry out in vitro dissolution test according to the second method of appendix two of version 2000: pH7.0 buffer salt 900ml is dissolution medium, temperature 37.5 ± 0.5 ℃, stirring paddle rotating speed is 50rpm, measure absorbance value at wavelength 238nm place, calculat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com