Nano modified polylactic acid and preparation method thereof

A nano-modified polylactic acid technology, which is applied in the field of polymer materials, can solve the problems of polylactic acid, such as flammability, poor comprehensive performance, and poor toughness, and achieve the effect of expanding the scope of application and improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

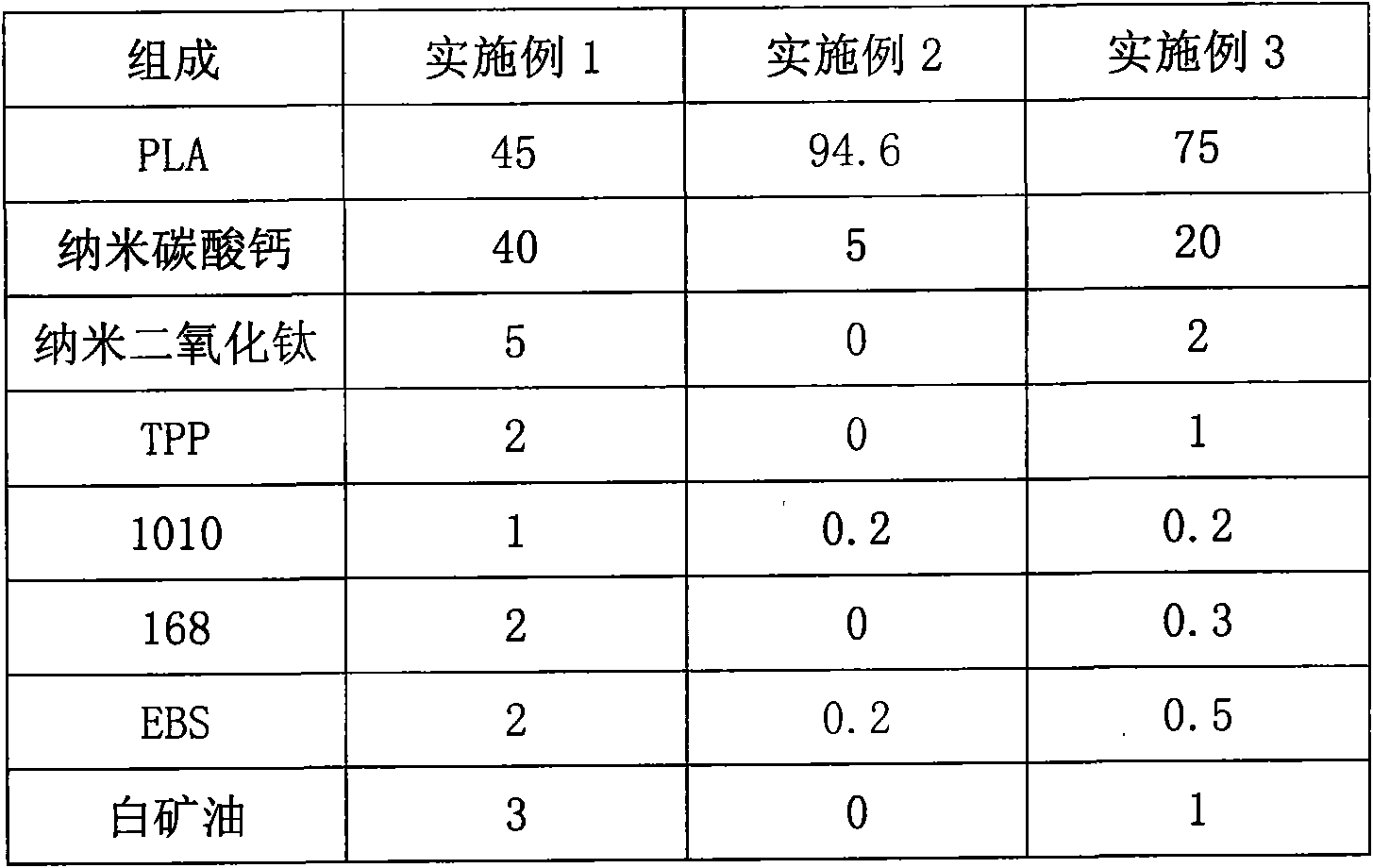

[0021] like figure 1 As shown, the nano-modified polylactic acid of this embodiment is mixed by polylactic acid, nanoparticles, heat stabilizer and processing aid, wherein the polylactic acid is 45wt%; the nanoparticles are calcium carbonate with an average particle size of 1 to 200nm and titanium dioxide mixture, wherein calcium carbonate is 40wt%, titanium dioxide is 5wt%; heat stabilizer is 2wt% triphenyl phosphite (TPP), 1wt% [3-(3,5-di-tert-butyl-4 -Hydroxyphenyl)propionic acid]pentapentylthritol ester (1010) and 2 wt% mixture of (2,4-di-tert-butylphenyl)phosphite (168); processing aids are lubricants and dispersants The mixture, wherein the dispersant is 3wt% white mineral oil, and the lubricant is 2wt% N, N'-ethylene bisstearamide (EBS).

[0022] Above-mentioned nano-modified polylactic acid adopts following preparation method:

[0023] A: Put the weighed polylactic acid, nanoparticles, heat stabilizer and processing aid in a high-speed mixer and mix for 300 seconds; ...

Embodiment 2

[0029] like figure 1 As shown, different from the above-mentioned Example 1, the nano-modified polylactic acid of this embodiment is mixed by polylactic acid, nanoparticles, thermal stabilizers and processing aids, wherein the polylactic acid is 94.6wt%; the nanoparticles are 5wt% calcium carbonate with an average particle diameter of 1 to 200nm; the thermal stabilizer is 0.2wt% [3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid] pentapentyl ester ( 1010); the processing aid is a lubricant, specifically 0.2 wt% of N,N'-ethylene bisstearic acid amide (EBS).

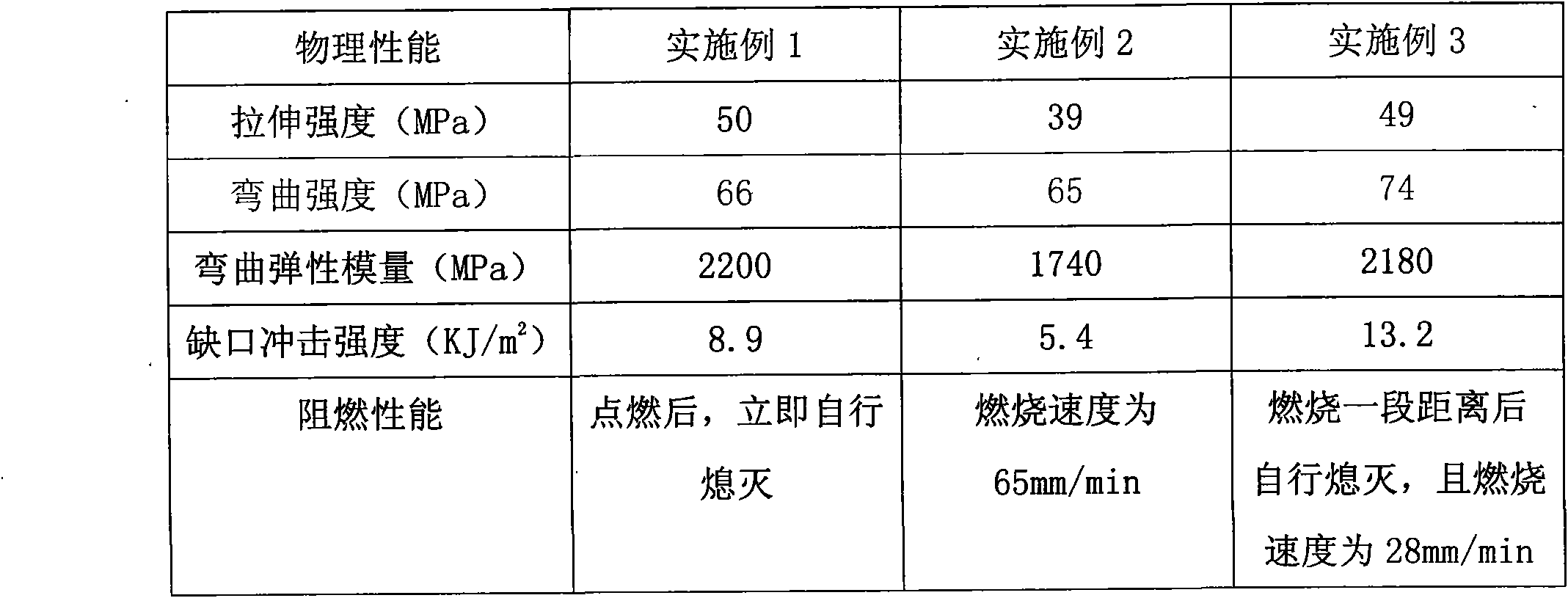

[0030] After testing, the performance of the above-mentioned nano-modified polylactic acid is as follows: figure 2 As shown, its tensile strength, flexural strength, flexural modulus, notched impact strength and flame retardancy are good, and it is suitable for auto parts, household appliances, precision electronic instruments and plastic processing industries.

[0031] The above-mentioned nano-modified polylactic aci...

Embodiment 3

[0033] like figure 1 As shown, different from the above-mentioned Examples 1 and 2, the nano-modified polylactic acid of this embodiment is mixed by polylactic acid, nanoparticles, thermal stabilizers and processing aids, wherein the polylactic acid is 75wt%; It is a mixture of calcium carbonate and titanium dioxide with an average particle size of 1 to 200nm, wherein calcium carbonate is 20wt%, and titanium dioxide is 2wt%; the thermal stabilizer is 1wt% triphenyl phosphite (TPP), 0.2wt% [3 -(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentapentylitol ester (1010) and 0.3wt% (2,4-di-tert-butylphenyl) phosphite (168 ) mixture; the processing aid is a mixture of a lubricant and a dispersant, wherein the dispersant is 1wt% white mineral oil, and the lubricant is 0.5wt% N, N'-ethylene bis stearic acid amide (EBS).

[0034] After testing, the performance of the above-mentioned nano-modified polylactic acid is as follows: figure 2 As shown, its tensile strength, flexural stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com