Water-based radon-proof interior wall coating

A technology for interior wall coatings and radon gas, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of inability to form paint films, paint film pulverization and damage, and inability to shield radon gas diffusion, so as to reduce transportation and ensure The effect of reliability and good radiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

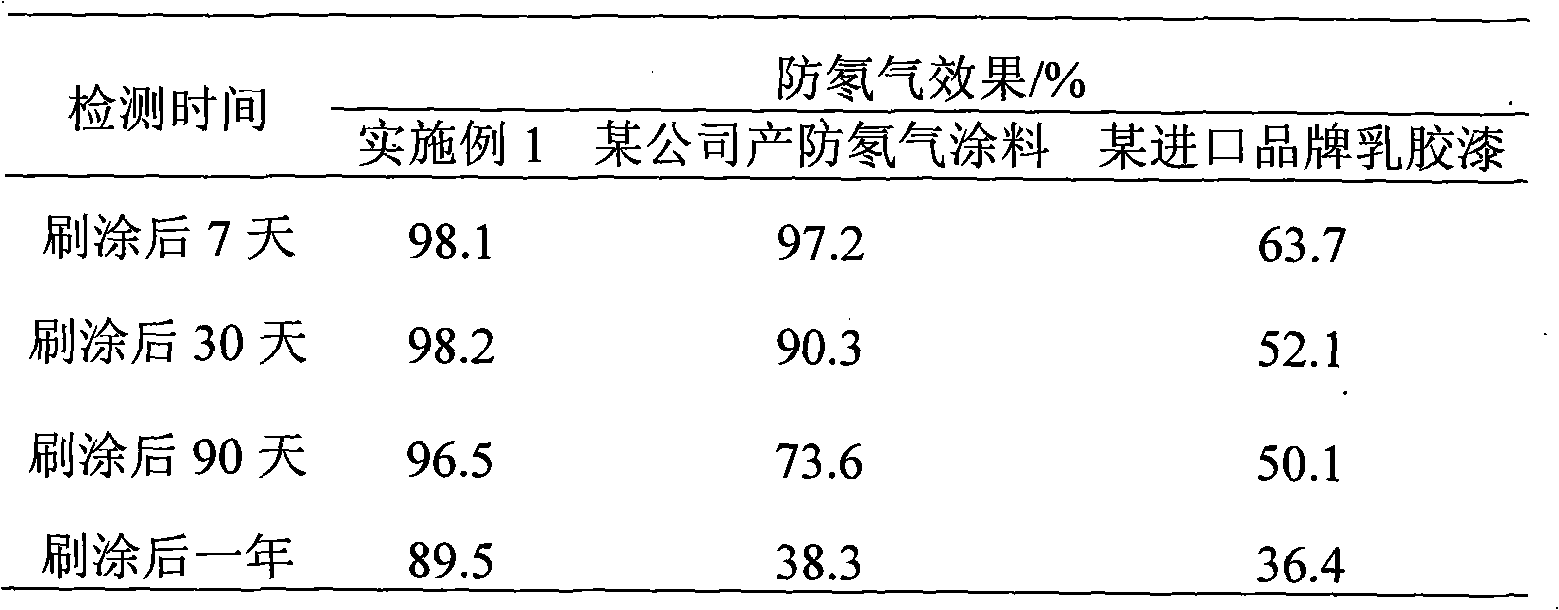

Examples

preparation example Construction

[0030] The preparation method of product of the present invention is:

[0031] A component

[0032] Mix part of the water with pigments and additives evenly, then add the remaining water and other raw materials, mix evenly, and filter to obtain component A;

[0033] Component B is obtained by stirring the raw materials evenly and filtering.

Embodiment 1

[0035] The composition of A component is:

[0036] 16 parts of deionized water, 25 parts of titanium dioxide, 52 parts of water-based epoxy resin emulsion, 2 parts of water-based color paste, 0.4 parts of defoamer (BYK 012), 0.6 parts of thickener (Deqian Chemical 105A);

[0037] The composition of B component is:

[0038] 22 parts of deionized water, 23 parts of water-based epoxy curing agent, 25 parts of heavy calcium carbonate, 35 parts of talcum powder, 0.4 parts of wetting agent (Deqian Chemical W19), 0.2 parts of defoamer (BYK 012), leveling 0.4 part of agent (Efka 3034).

Embodiment 2

[0040] The composition of A component is:

[0041] 12 parts of deionized water, 24 parts of titanium dioxide, 60 parts of water-based epoxy resin emulsion, 0.5 parts of defoamer (BYK012), 0.5 parts of thickener;

[0042] The composition of B component is:

[0043] 19 parts of deionized water, 27 parts of water-based epoxy curing agent, 50 parts of heavy calcium carbonate, 0.6 parts of wetting agent (Deqian Chemical W19), 0.3 parts of defoamer (Deqian Chemical 082), 0.7 parts of leveling agent (Efka 3034).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com