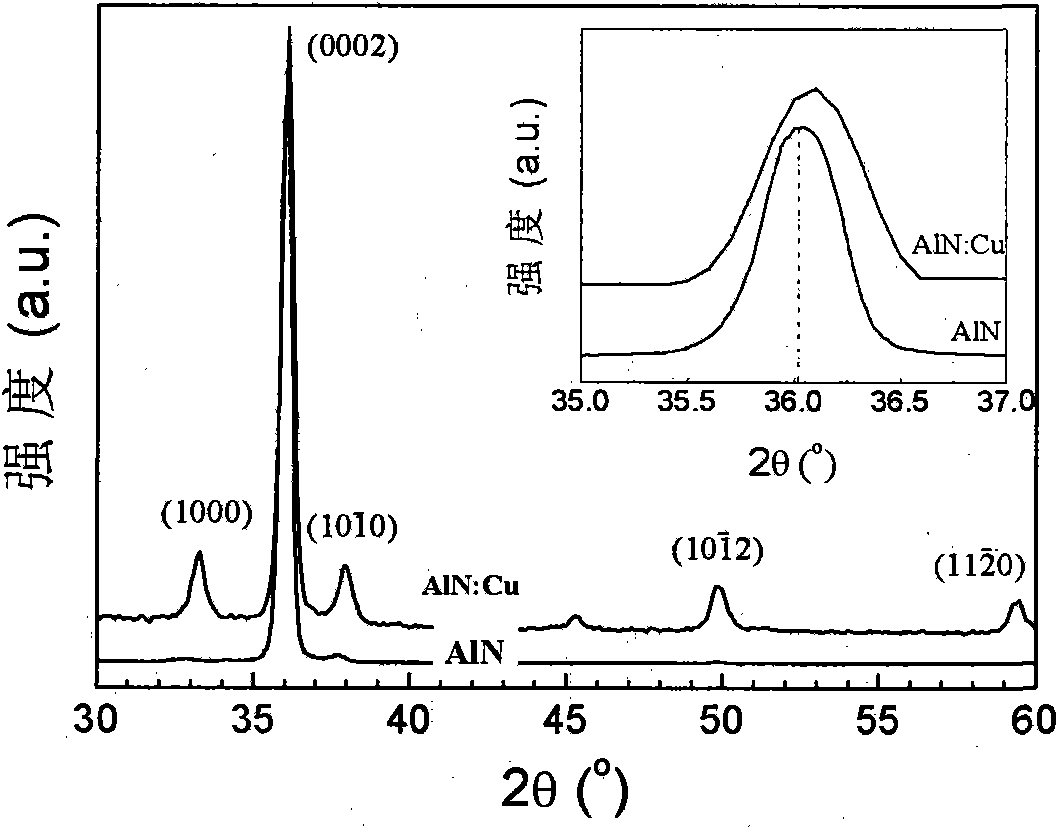

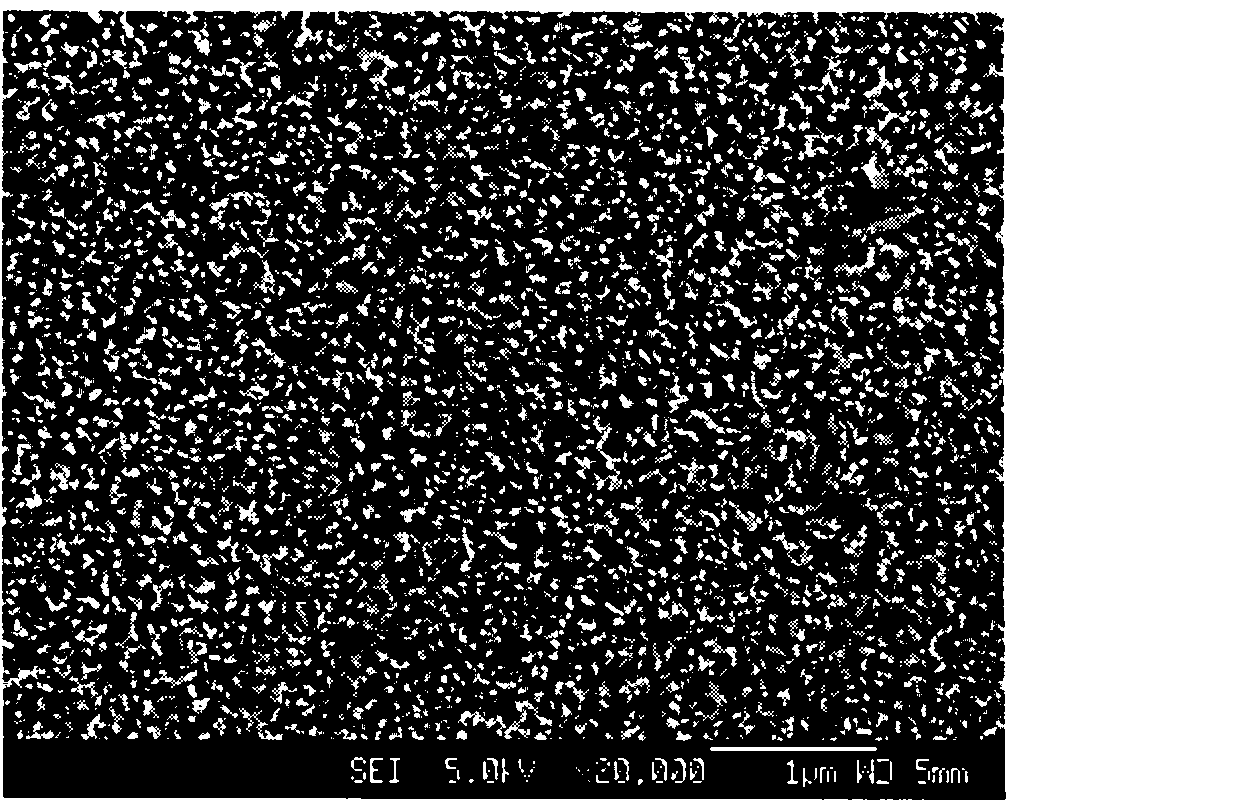

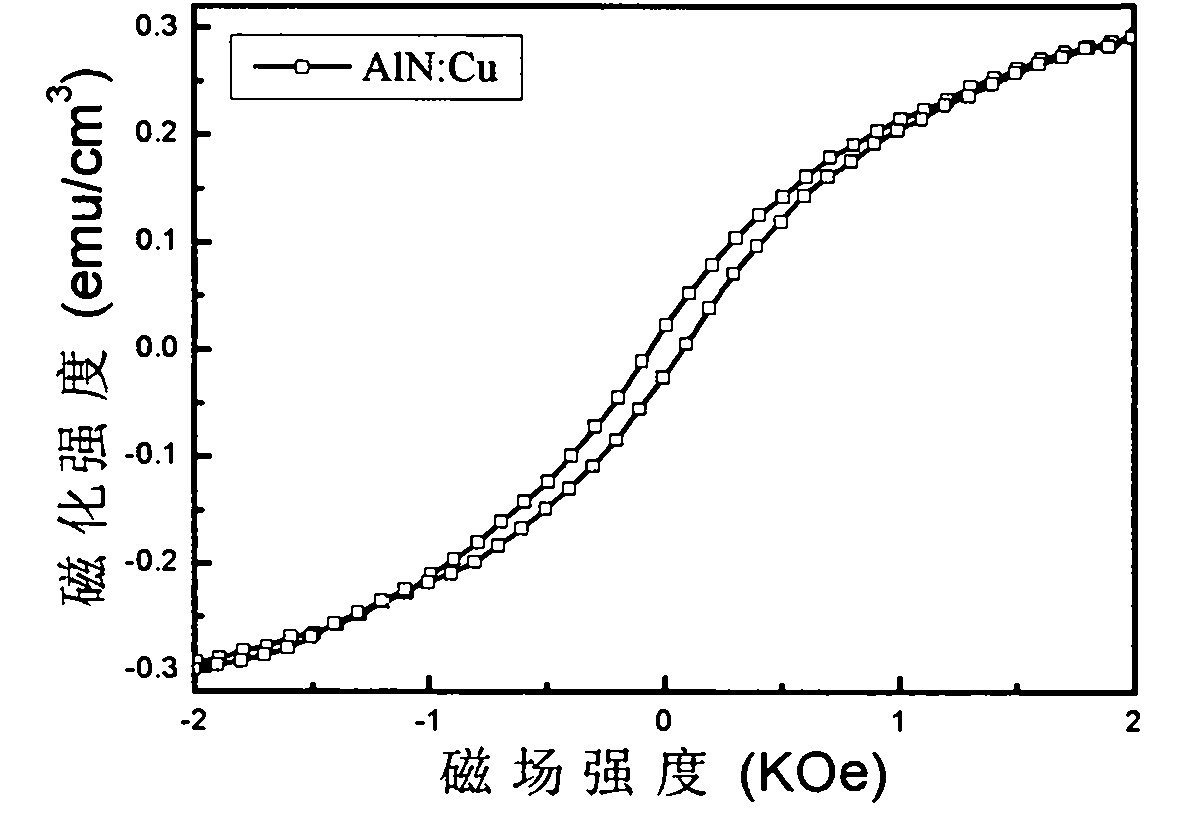

Method for preparing copper-doped aluminum nitride base diluted magnetic semiconductor nano rods

A dilute magnetic semiconductor, aluminum nitride-based technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, to achieve broad application prospects, low equipment requirements, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) AlCl 3 with CuCl 2 mix;

[0023] (2) Place the crucible and the silicon substrate containing the mixture in the quartz tube, close the quartz tube, push the quartz tube into the furnace so that the crucible is not heated, and vacuumize;

[0024] (3) Control the temperature of the furnace to rise to 900-950°C within half an hour, and at the same time feed nitrogen gas with a flow rate of 100 sccm; then push the quartz tube further into the furnace to heat the mixture and the silicon substrate, keeping the flow rate of nitrogen gas constant, Inject ammonia gas for 30 minutes, with a flow rate of 20 sccm; then reduce the flow rate of ammonia gas to 5 sccm, and pass it for 30 minutes to obtain copper-doped aluminum nitride-based dilute magnetic semiconductor nanorods.

[0025] 1) Cut the Si sheet into strips with a width of 1 cm, ultrasonically clean it with acetone and alcohol, and dry it with nitrogen gas for later use;

[0026] 2) AlCl 3 powder with CuCl 2 Put t...

Embodiment 2

[0036] 1) Cut the Si sheet into strips with a width of 1 cm, ultrasonically clean it with acetone and alcohol, and then dry it with nitrogen to obtain a Si substrate;

[0037] 2) High-purity AlCl 3 powder with CuCl 2 The powders are physically mixed in a ratio of 9.5:1 according to the molar ratio;

[0038] 3) put the mixed powder into an alumina crucible, and place it in a quartz tube with two ends open, a diameter of 60mm, and a length of 1 meter;

[0039] 4) Place the prepared Si substrate in the quartz tube; the distance between the crucible and the silicon substrate is 8cm;

[0040] 5) Push the quartz tube into the horizontal tubular atmosphere furnace to keep the source end from being heated;

[0041] 6) Close the quartz tube, evacuate to 0.1Pa, and then flush into nitrogen for cleaning;

[0042] 7) Introduce 100 sccm nitrogen gas from one end of the reaction source as the carrier gas, and set the temperature rise program so that the system rises to 950°C within half...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com