Amoxicillin sodium potassium clavulanate composition microballoon injection

A technology for amoxicillin sodium clavulanate potassium and amoxicillin sodium is applied in the field of pharmaceutical preparations, can solve the problems of poor stability, undisclosed amoxicillin sodium clavulanate potassium, poor clarity and the like, and achieves improved stability. , reduce drug toxicity, prolong the effect of drug efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Embodiment 1 Preparation of Amoxicillin Sodium Clavulanate Potassium Pharmaceutical Composition Microsphere Injection

[0069] Prescription: (100 bottles)

[0070] Amoxicillin Sodium 50g

[0071] Potassium clavulanate 10g

[0072] Gelatin 40g

[0073] Gum Arabic 40g

[0074] Disodium hydrogen phosphate 30g

[0075] Trehalose 20g

[0076] Glycerin 10g

[0077] making process:

[0078] (1) Dissolve 40g of gelatin and 40g of gum arabic in 500ml of water for injection, add 50g of amoxicillin sodium, 10g of potassium clavulanate, 10g of glycerin, 20g of trehalose and 30g of disodium hydrogen phosphate;

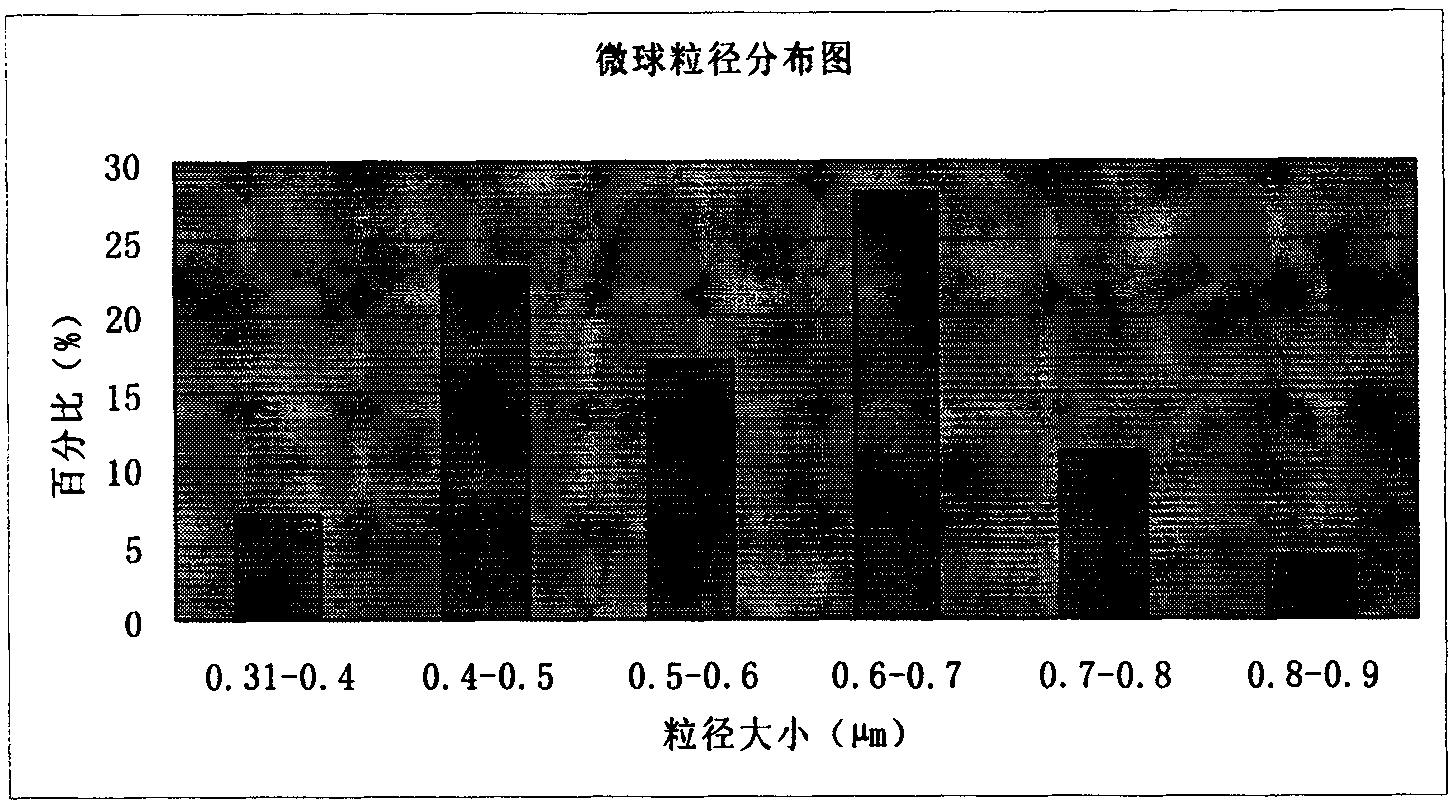

[0079] (2) Put the above solution into the spray dryer, adjust the spray conditions (the inlet temperature is 85°C, the outlet temperature is about 40°C, the nozzle size is 0.5mm, the spray flow rate is 5ml / min, and the compressed air velocity is 8L / min) to spray dry , to obtain white microspheres with uniform shape;

[0080](3) The obtained microspheres were finall...

Embodiment 2

[0095] Example 2 Preparation of Amoxicillin Sodium Clavulanate Potassium Pharmaceutical Composition Microsphere Injection

[0096] Prescription: (100 bottles)

[0097] Amoxicillin Sodium 50g

[0098] Potassium clavulanate 10g

[0099] Gelatin 45g

[0100] Gum Arabic 45g

[0101] Disodium hydrogen phosphate 40g

[0102] Trehalose 30g

[0103] Glycerin 15g

[0104] making process:

[0105] (1) Dissolve 45g of gelatin and 45g of gum arabic in 600ml of water for injection, add 50g of amoxicillin sodium, 10g of potassium clavulanate, 15g of glycerin, 30g of trehalose and 40g of disodium hydrogen phosphate;

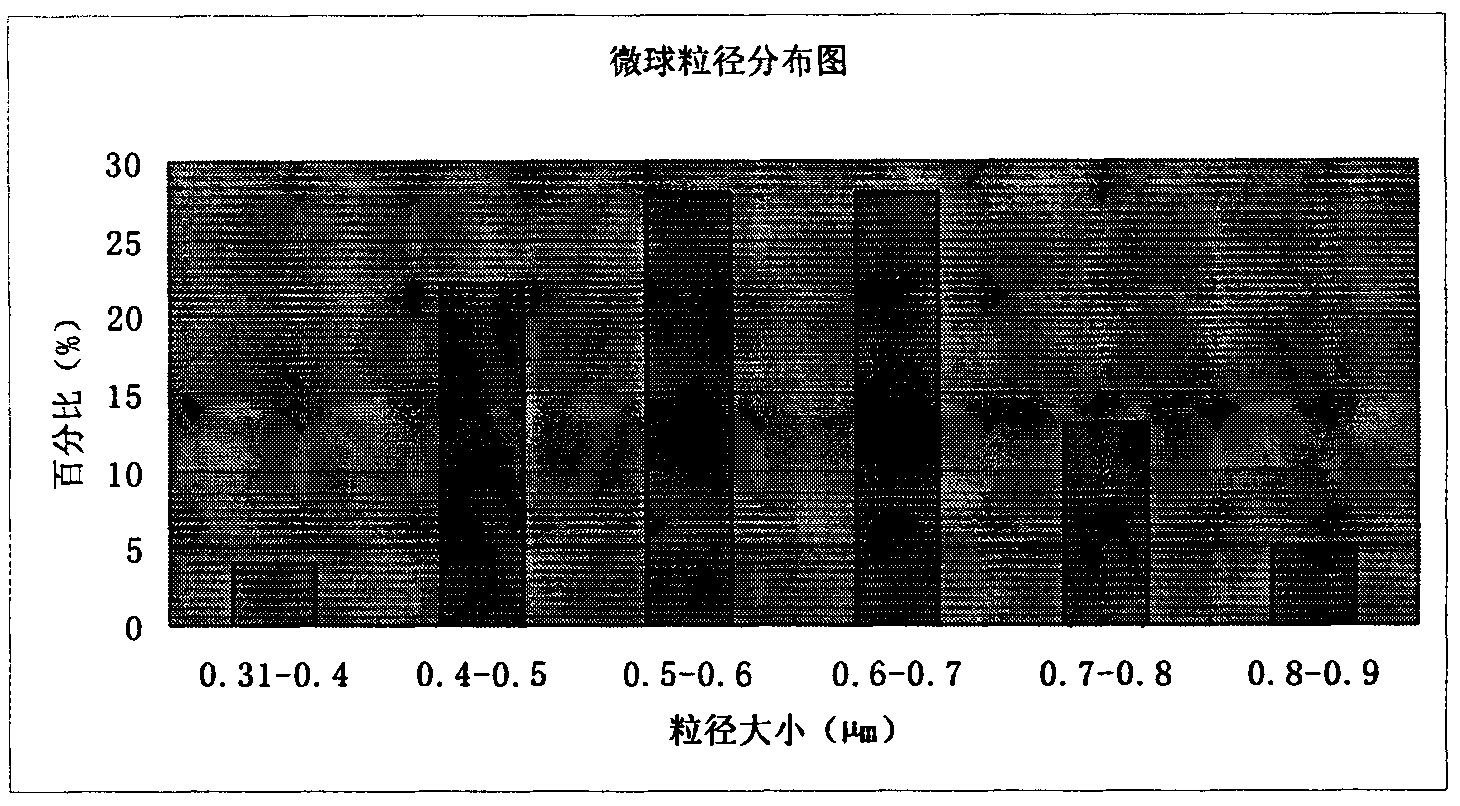

[0106] (2) Put the above solution into the spray dryer, adjust the spray conditions (inlet temperature is 80°C, outlet temperature is about 30°C, nozzle size is 1mm, spray liquid flow rate is 10ml / min, compressed airflow speed is 15L / min) spray drying, Obtain white microspheres with uniform shape;

[0107] (3) Finally, heat and solidify the obtained microspheres at a t...

Embodiment 3

[0120] Example 3 Preparation of Amoxicillin Sodium Clavulanate Potassium Pharmaceutical Composition Microsphere Injection

[0121] Prescription: (100 bottles)

[0122] Amoxicillin Sodium 50g

[0123] Potassium clavulanate 10g

[0124] Gelatin 60g

[0125] Gum Arabic 60g

[0126] Disodium hydrogen phosphate 60g

[0127] Trehalose 40g

[0128] Glycerin 30g

[0129] making process:

[0130] (1) Dissolve 60g gelatin and 60g gum arabic in 3000ml water for injection, add 50g sodium amoxicillin, 10g potassium clavulanate, 30g glycerin, 40g trehalose and 60g disodium hydrogen phosphate;

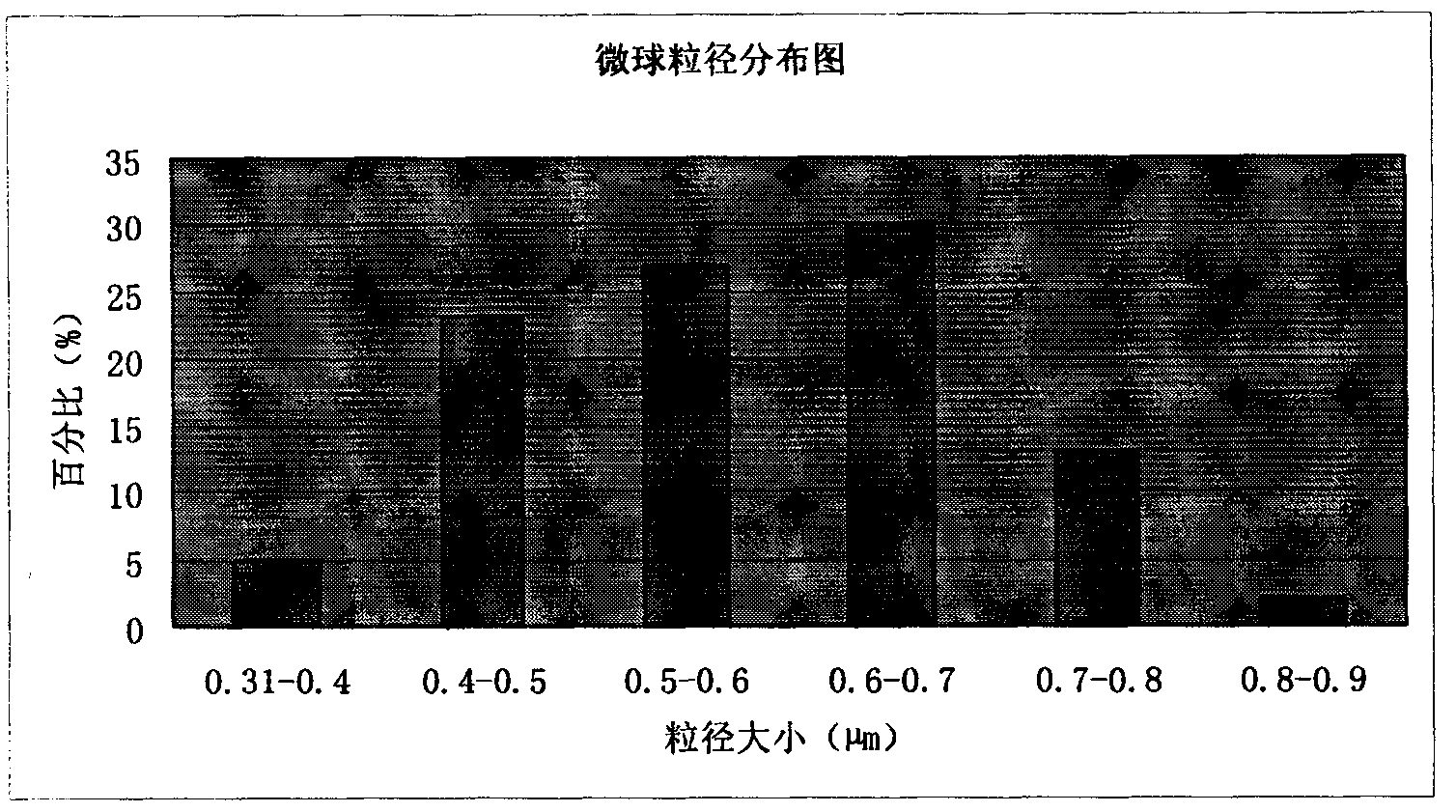

[0131] (2) Put the above solution into the spray dryer, adjust the spray conditions (inlet temperature is 90°C, outlet temperature is about 40°C, nozzle size is 0.8mm, spray flow rate is 7ml / min, compressed air velocity is 12L / min) spray drying , to obtain white microspheres with uniform shape;

[0132] (3) Finally, heat and solidify the obtained microspheres at a temperature of 120° C. for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| encapsulation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com