Method for preparing high-purity calcium carbonate superfine powder from carbide slag

A technology of ultra-fine calcium carbonate and calcium carbide slag, which is used in the removal of calcium carbonate/strontium/barium, solid waste, etc., and can solve the problems of low purity, adverse effects on the environment and operator's health, and large particle size of calcium carbonate products. , to achieve the effect of improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

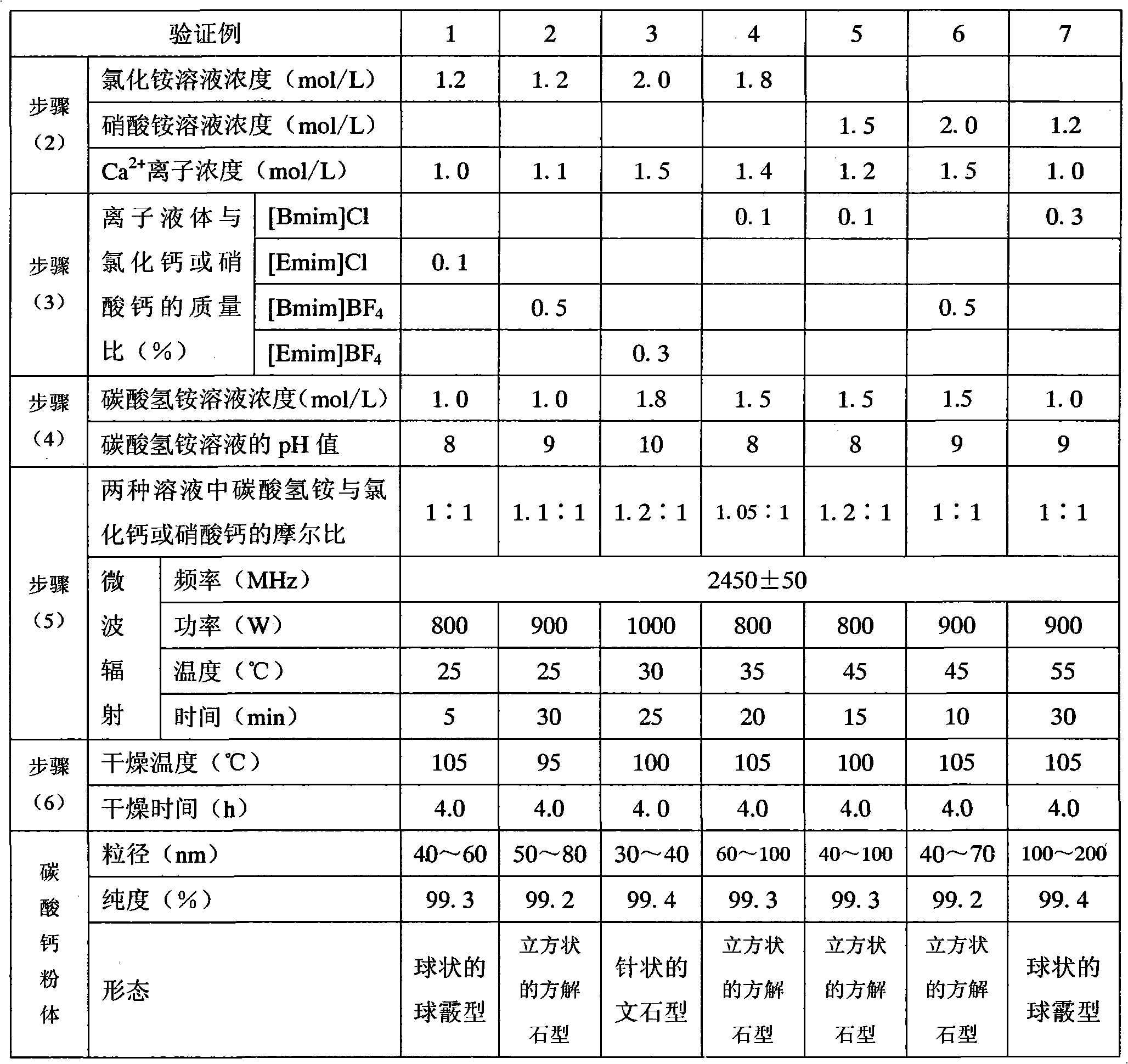

Examples

Embodiment Construction

[0015] A kind of method utilizing calcium carbide slag to prepare high-purity ultrafine calcium carbonate, comprising ammonium chloride solution in the leaching agent used in this method, one of leaching agent can also be ammonium nitrate solution among the present invention, and comprises the following steps:

[0016] (1) Crush the calcium carbide slag and sieve it through a 100-mesh sieve, and then heat and burn it at 300°C to 500°C (it is best to use microwave heating and combustion to increase the burning speed and shorten the burning time) to remove the residual volatile matter in the carbide slag. Volatile organic substances and impurities: hydrogen sulfide, phosphine, acetylene gas and other volatile organic impurities and residues;

[0017] (2) Mix the calcium carbide slag pretreated in step (1) and cooled to room temperature with ammonium chloride solution or ammonium nitrate solution with a concentration of 1.2 to 2.0 mol / L, and fully stir for leaching (usually The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com