Tellurium-based sulfur series infrared glass and preparation method thereof

An infrared glass and chalcogenide technology, applied in the field of infrared glass materials, can solve the problems of narrow available spectral range and large influence of multi-phonon absorption, etc., and achieve the effects of increased available spectral range, suitable transition temperature, and strong glass-forming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

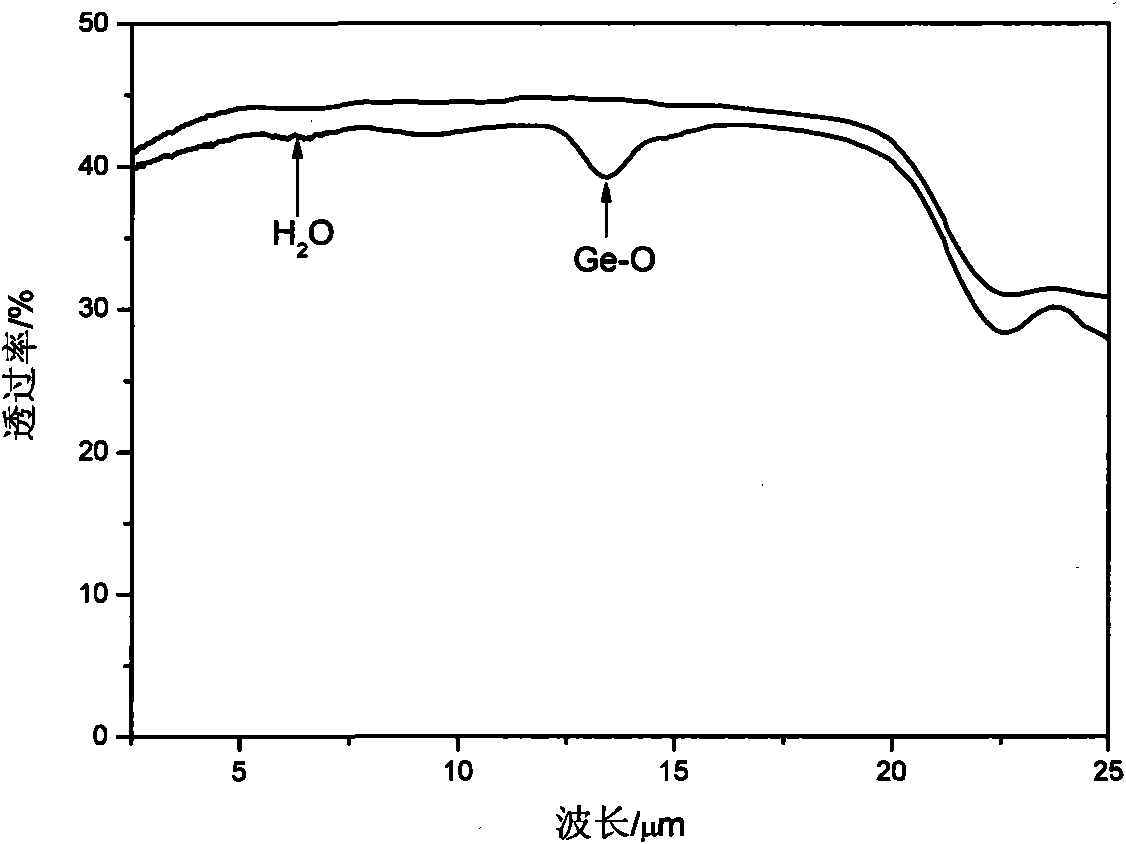

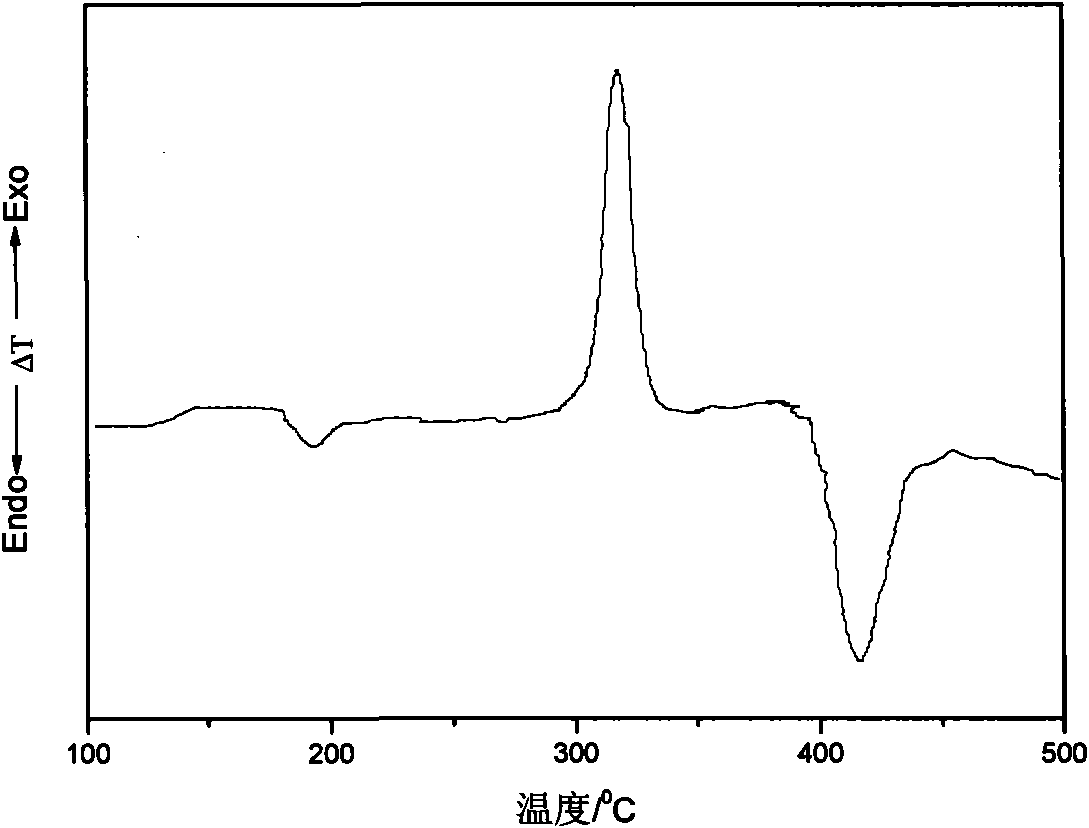

[0023] A tellurium-based chalcogenide infrared glass, the glass composition is: 20mol% In 2 Te 6 , 60mol% GeTe 4 And 20mol%AgI, according to this component requirement, calculate the weight percent that needs AgI raw material to be 7.88%, the weight percent of elemental raw material In is 7.71%, the weight percent of Ge is 7.31%, the weight percent of Te is 77.10%, press Weight ratio Silver halide with a purity of ≥99.9%, indium, germanium and tellurium with a purity of ≥99.99%, are mixed to form a glass mixture, and 0.1wt% magnesium strips are added to the glass mixture: 0.1wt% is is the weight percent concentration of magnesium strips in the glass mixture. Magnesium strips can react with oxides in raw materials to remove oxygen impurities in raw materials and play a role in purifying raw materials. At the same time, magnesium is not mixed with glass melting; The mixture is put into one of the quartz tubes of the H-shaped double-tube quartz ampoule. The H-shaped double-tube...

Embodiment 2

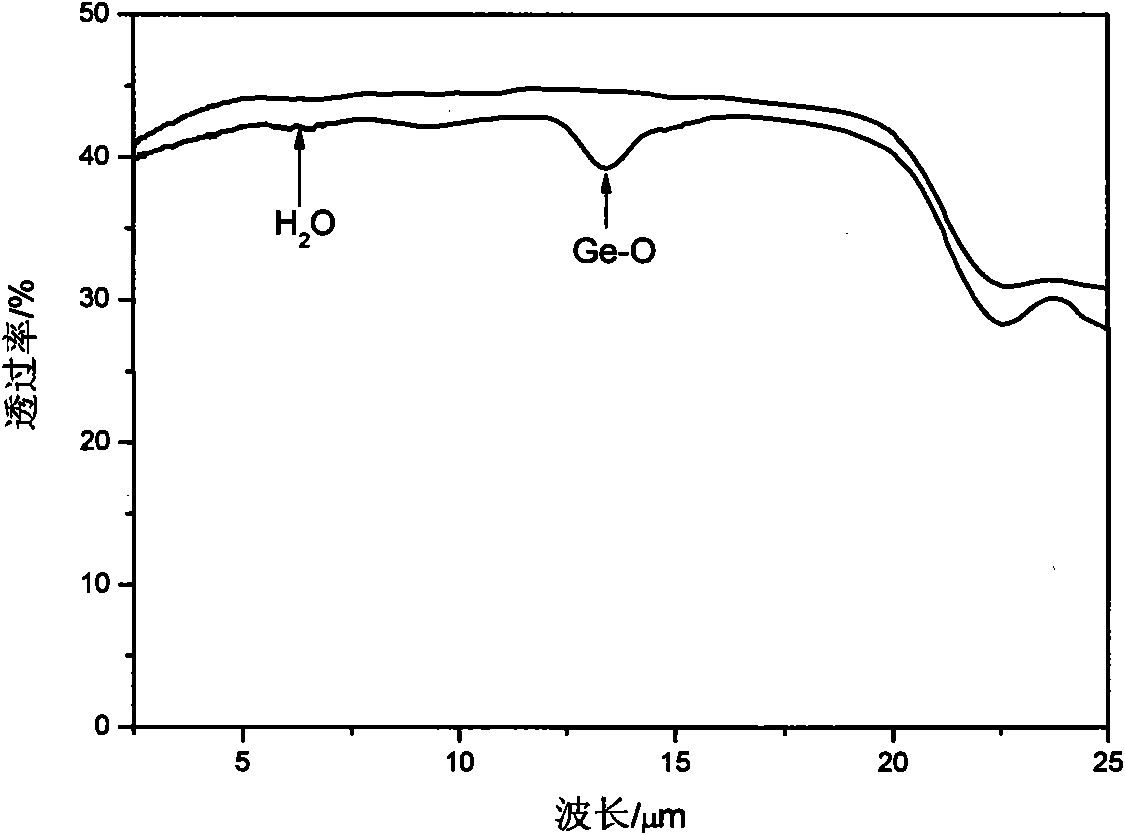

[0027]A tellurium-based chalcogenide infrared glass, which is basically the same as in Example 1, except that the composition of the glass is: 15mol% In 2 Te 6 , 70mol% GeTe 4 And 15mol% AgBr, so the weight percentage of AgBr raw material is 4.82%, the weight percentage of elemental raw material In is 5.88%, the weight percentage of Ge is 8.68%, the weight percentage of Te is 80.62%, and the vacuum degree in the ampoule can be met in addition Requirements≤3×10 -3 Pa, the cold end temperature of distillation purification is 20°C.

Embodiment 3

[0029] A tellurium-based chalcogenide infrared glass, which is basically the same as in Example 1, except that the glass has a composition of: 10mol% In 2 Te 6 , 45mol% GeTe 4 and 45mol% AgBr, the weight percent calculation of specific raw materials is a conventional conversion method, which will not be described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com