Preparation method of biomass solid-molded composite fuel and biomass solid-molded composite fuel

A composite fuel and manufacturing method technology, applied in the direction of solid fuel, waste fuel, fuel, etc., can solve the problems of industrial waste polluting the environment and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

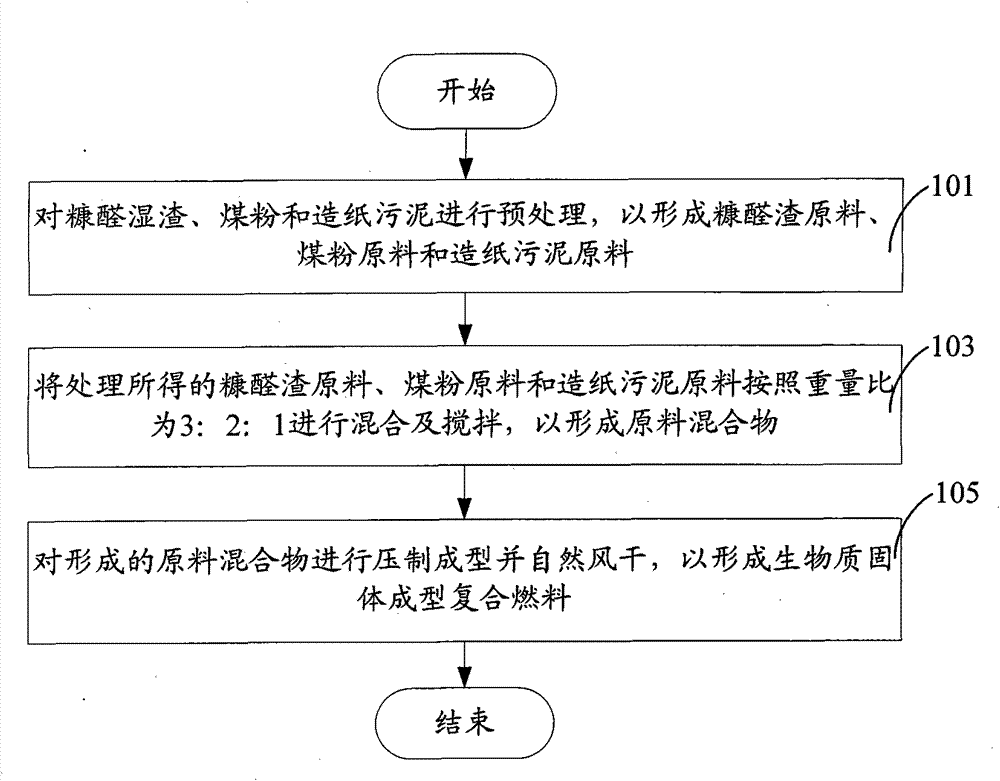

[0014] Such as figure 1 Shown is a flow chart of the manufacturing method of biomass solid briquette composite fuel in a preferred embodiment. The composite fuel manufacturing method comprises the following steps:

[0015] Step S101 , pretreating furfural wet slag, coal powder and papermaking sludge to form furfural slag raw material, coal powder raw material and papermaking sludge raw material. Among them, the pretreatment of furfural wet slag refers to dehydration and drying of furfural wet slag to a water content of 10-40%; the pretreatment of coal powder refers to pulverizing coal powder to a particle size of 0.1-0.3 cm, and the coal powder can be Anthracite coal powder, coke coal powder, bituminous coal powder or a mixture of the above coal powder; the pretreatment of papermaking sludge refers to dehydration and drying of papermaking sludge to a water content of 10-40%. The part is the combustible part (wood fiber, semi-fiber, starch, etc.) and the non-combustible part ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com