Method for extracting juglone from walnut green husk residue by microwave reflux

A technology of microwave reflux and walnut green husk, which is applied in quinone separation/purification, organic chemistry, etc., to achieve the effects of avoiding thermal decomposition, high extraction rate and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 10 kg green bark is crushed with a crusher and filtered. Take the crushed material and adjust the solid-liquid ratio to 1:8 with chloroform, put it in a microwave oven reflux device, and extract it under a microwave power series for 25 minutes under a warm fire, remove it and filter it with suction to obtain a juglone quinone leaching solution. Extract the filter residue once more, wash the filter residue with solvent for 3 times, collect all the solution, and concentrate by rotary evaporation under reduced pressure to obtain the product juglone. Chloroform is recycled.

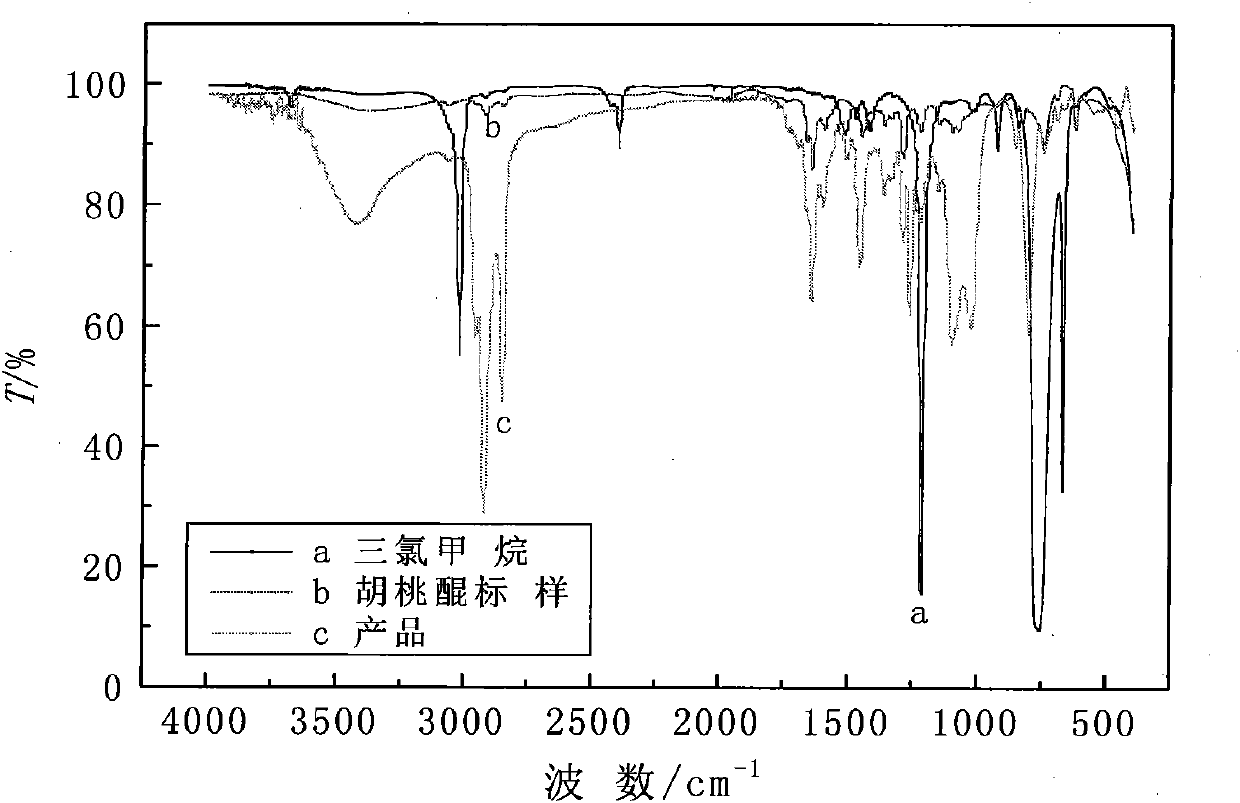

[0021] The product juglone was tested for each index. Wherein, by AVATAR360 type Fourier transform infrared spectrometer, obtain juglone standard substance and sample collection of illustrative plates (see attached figure 1 ), and analyzed and compared, it was determined that the product was juglone.

[0022] The calculated juglone extraction rate was 85%, the purity was 92%, and the yield was 0.19%...

Embodiment 2

[0028] 10 kg green bark is crushed with a crusher and filtered. Take the crushed material and adjust the solid-liquid ratio to 1:5 with chloroform, put it in a microwave oven reflux device, and extract it under a microwave power series for 30 minutes under a warm fire, remove it and filter it with suction to obtain a juglone extract. Extract the filter residue once more, combine the two extracts, wash the filter residue 5 times with a solvent, collect all the solutions, and concentrate by rotary evaporation under reduced pressure to obtain the product juglone. Chloroform is recycled. The product juglone was tested for each index. The extraction rate of juglone was 93%, the purity was 81.5%, and the yield was 0.20%.

Embodiment 3

[0030] 10 kg green bark is crushed with a crusher and filtered. Take the crushed material and adjust the solid-liquid ratio to 1:6 with chloroform, put it in a microwave oven reflux device, and extract it under a microwave power series for 20 minutes under a warm fire, remove it and filter it with suction to obtain a juglone quinone leaching solution. Extract the filter residue once more, combine the two extracts, wash the filter residue 4 times with a solvent, collect all the solutions, and concentrate by rotary evaporation under reduced pressure to obtain the product juglone. Chloroform is recycled. The product juglone was tested for each index. The extraction rate of juglone was 88%, the purity was 85%, and the yield was 0.19%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com