Manufacturing method of high-temperature resistant and corrosion-resistant polyphenyl thioether composite tube

A polyphenylene sulfide and composite pipe technology, which is applied in the direction of tubular objects, other household appliances, household appliances, etc., can solve the problem of affecting mechanical properties, reducing the bending impact strength and tensile strength of composite pipes made of polyphenylene sulfide composite materials, and the effect Unsatisfactory and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

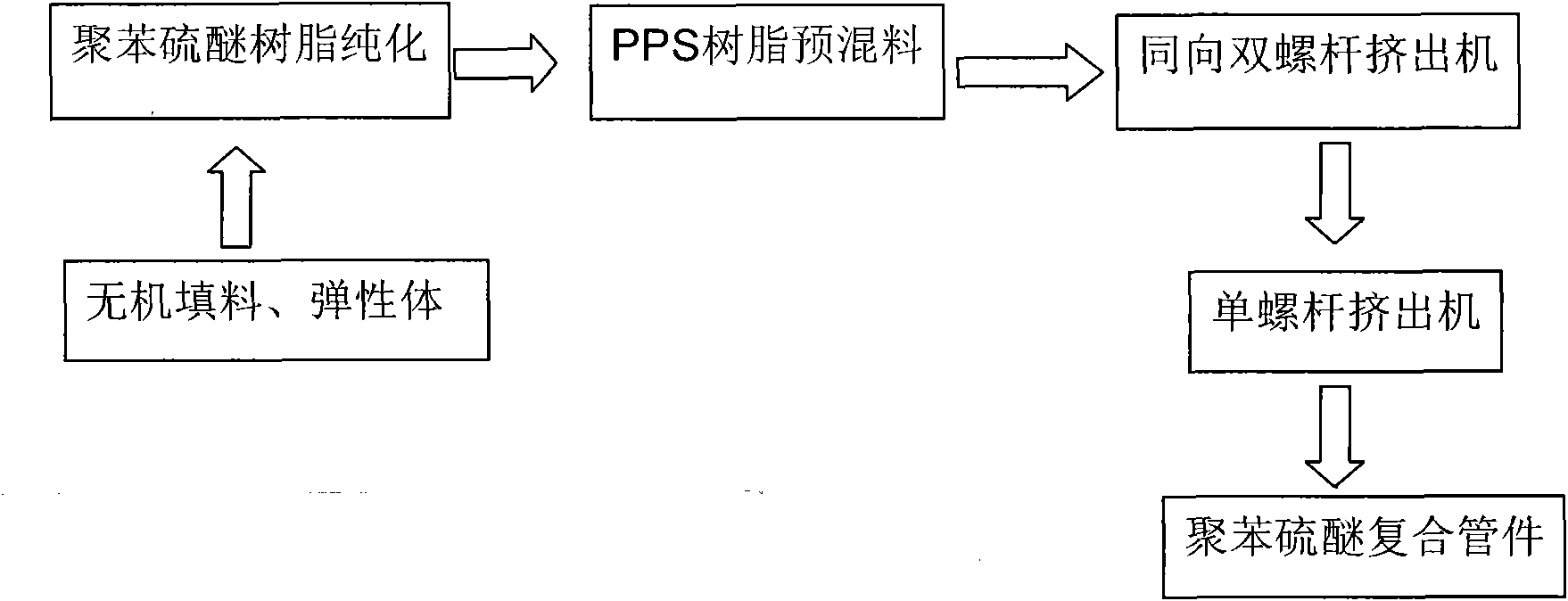

Method used

Image

Examples

Embodiment 1

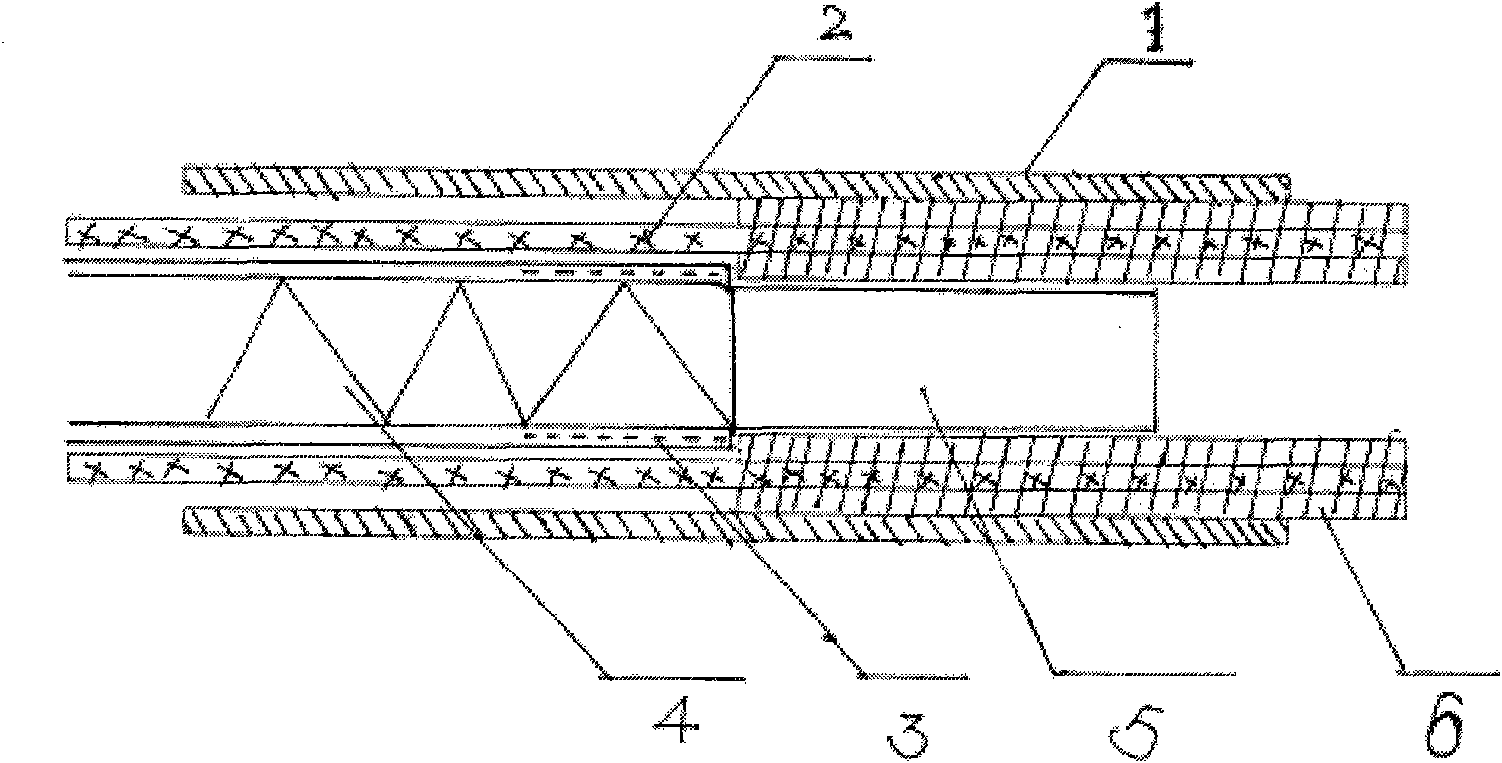

[0026] Polyphenylene sulfide resin, add 10% 0.1mm silicon carbide fiber, 0.5% N-stearyl lysine zinc salt, 3% KHT-108 compatibilizer, ETPU elastomer 10%wt mixed in a high-speed mixer 100% polyphenylene sulfide compound, the obtained polyphenylene sulfide resin premix is mixed and extruded by a twin-screw extruder and introduced into a single-screw extruder, and the 3-layer basalt fiber and heated Modified aramid fiber III (that is, polyaramid containing aromatic heterocycle) fiber cloth and polyphenylene sulfide after stretching treatment are extruded through the tubular die of the head of the extruder. Gas-cooled and formed to obtain polyphenylene sulfide composite pipes. And the fiber cloth accounts for 30%wt of the polyphenylene sulfide premix. Cylindrical basalt fiber and modified aramid III (that is, polyaramid containing aromatic heterocycle) fiber cloth is made of 30% basalt long fiber and 70% modified aramid III (that is, containing aromatic heterocycle) Heterocycli...

Embodiment 2

[0029] Polyphenylene sulfide resin, add 11% 5 nanometer grade titanium dioxide, 0.7% N-stearyl lysine magnesium salt, 3.1% KHT-201 compatibilizer, ETPU elastomer 11%wt mixed in a high-speed mixer to 100% The polyphenylene sulfide compound, the obtained polyphenylene sulfide resin premix is mixed and extruded by the twin-screw extruder and introduced into the single-screw extruder, and the 4-layer basalt fiber and the heat-stretching treatment The final modified aramid III (that is, polyaramid containing aromatic heterocycle) fiber cloth and polyphenylene sulfide composite melt extruder head extruded through a tubular die, and the drawn tube is cooled by helium at a temperature of -20°C Shaped to obtain a polyphenylene sulfide composite pipe. And the fiber cloth accounts for 31%wt of the polyphenylene sulfide premix. Cylindrical basalt fiber and modified aramid III (that is, polyaramid containing aromatic heterocycle) fiber cloth is made of 35% basalt long fiber and 65% modi...

Embodiment 3

[0032] Polyphenylene sulfide resin, add 13% of 0.2mm silicon carbide fiber, 1.1% N-stearyl lysine magnesium salt, 3% KHT-303 compatibilizer, ETPU elastomer 12%wt and mix it in a high-speed mixer 100% polyphenylene sulfide compound, the obtained polyphenylene sulfide resin premix is mixed and extruded by a twin-screw extruder and introduced into a single-screw extruder, and the 5-layer basalt fiber and heated The modified aramid fiber III (that is, polyarylamide containing aromatic heterocycle) fiber cloth and polyphenylene sulfide composite melt extruder after stretching treatment is extruded through a tubular die, and the tube is drawn with helium at a temperature of -22°C. Gas-cooled and formed to obtain polyphenylene sulfide composite pipes. And the fiber cloth accounts for 35%wt of the polyphenylene sulfide premix. Cylindrical basalt fiber and modified aramid III (that is, polyaramid containing aromatic heterocycle) fiber cloth is made of 40% basalt long fiber and 60% m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com