Foamed ceramic reinforcing fiber aerogel insulating material and preparation method thereof

A technology of foam ceramics and reinforced fibers, which is applied in the field of heat insulation materials and its preparation, can solve the problems of high risk, high cost, and high brittleness, and achieve the effects of shortening drying time, reducing preparation costs, and improving heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

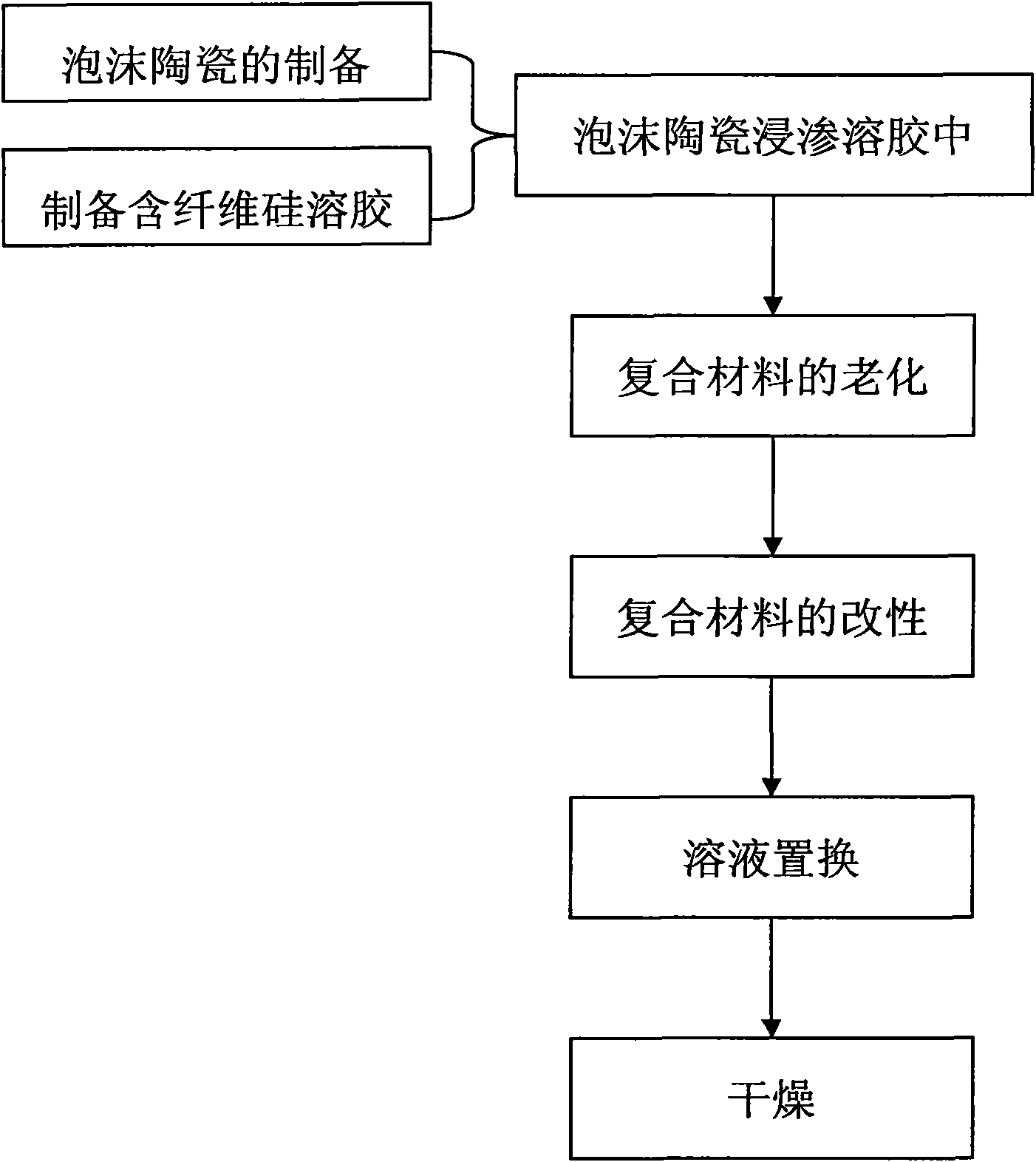

Method used

Image

Examples

Embodiment 1

[0034] Mix and stir 0.1 mol of tetraethyl orthosilicate, 0.4 mol of ethanol, and 0.6 mol of water, add mullite fiber (ie 1.04 g) according to the mass ratio of fiber to airgel of 1:20, stir for 3 minutes, then add hydrochloric acid (1 mol / L), adjust the pH to 3.5, add ammonia water (10mol / L) after stirring for 30 minutes at 50°C, adjust the pH to 8.0, and put the alumina porous ceramic into the sol after stirring for 60 seconds, and put it into a vacuum device Medium (DZF-6020B of Shanghai Anting Scientific Instrument Co., Ltd.), the vacuum degree is 73.5Mpa, the temperature is 25°C, take it out after 30min and place it in a mixed solution of tetraethyl orthosilicate: ethanol: water, and its molar ratio is 1 : 4:6 (0.2 mol of ethyl orthosilicate, 0.8 mol of ethanol, 1.2 mol of water), after 48 hours, take it out and put it into the modifying solution containing trimethylchlorosilane and n-butanol, keep the temperature at 50°C for 24 hours, The surface of the wet gel was chemi...

Embodiment 2

[0037] The difference between this embodiment and Embodiment 1 is that silicon carbide foam ceramics are used instead of alumina foam ceramics. The compressive strength of the alumina foam ceramic reinforced fiber airgel thermal insulation material prepared in this example reaches 5.3MPa, and the thermal conductivity is 0.13W / K m, while the thermal conductivity of the silicon carbide foam ceramic alone is 0.25W / K m .

Embodiment 3

[0039] The difference between this embodiment and Embodiment 1 is that the added fiber is mullite fiber, and its mass ratio to airgel is adjusted to 1:5, that is, 4.06g of mullite fiber is added to obtain a thermal insulation material The compressive strength is 3.8MPa, and the thermal conductivity is 0.18W / K m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com