Method for producing primary-color low-fat crisp mushroom chips

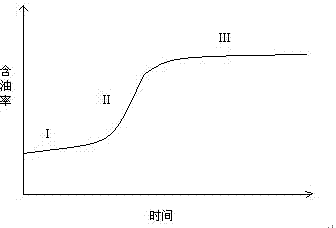

A production method and technology for shiitake mushrooms, which are applied in the fields of application, food preparation, food science, etc., can solve the problems of difficult to maintain color and shape, high technical oil content, and achieve the effects of improving product taste, reducing investment, and increasing unit output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: The production method of primary color low-fat shiitake mushroom crisps in the form of hot air drying after non-fried dehydration

[0039] 50kg of fresh shiitake mushrooms (moisture content on a wet basis is about 82%) are selected, removed, sliced (5mm-10mm), washed, color-protected for 10min-50min (0.5%NaCl+0.1%citric acid), blanched in the filling solution ( The mass fraction is 10% to 30% mixed filling liquid, maltodextrin mass: maltose mass = 2:1, 100°C, 3min to 6min), vacuum frying until the moisture content is about 30%, and the frying conditions are: vacuum degree 0.085 Mpa~0.098Mpa, the temperature in the fryer is 85℃~95℃, fry for 10min~20min (the specific situation is to observe the change of foaming in the fryer according to the glass window, take it out when there is less foaming), vacuum centrifuge Oil (speed 350rpm ~ 450rpm, time 2min ~ 4min). After deoiling, take it out and dry it with hot air. The specific conditions are: 40°C-70°C, 3h-5...

Embodiment 2

[0040] Embodiment 2: The production method of the original color low-fat shiitake mushroom chips in the form of vacuum drying after non-fried dehydration

[0041] 50kg of fresh shiitake mushrooms (moisture content on a wet basis is about 82%) are selected, removed, sliced (5mm-10mm), washed, color-protected for 10min-50min (0.5%NaCl+0.1%citric acid), blanched in the filling solution ( The mass fraction is 10% ~ 30% mixed filling liquid, maltodextrin mass: maltose mass = 3:2, 100 ° C, 3min ~ 6min), vacuum frying until the moisture content is about 30%, frying, deoiling conditions and implementation Example 1 is the same. After deoiling, take it out for vacuum drying, vacuum drying conditions: drying temperature 40°C-70°C, vacuum degree 0.080Mpa-0.090Mpa, drying time 2h-3h. Re-seasoning (salt 0.5%, sugar 2%, I+G 0.01%, monosodium glutamate 0.2%) and packaging.

Embodiment 3

[0042] Embodiment 3: The production method of primary color low-fat shiitake mushroom crisps with non-fried dehydration as the heat pump drying method in the later stage

[0043] 50kg of fresh shiitake mushrooms (moisture content on a wet basis is about 82%) are selected, removed, sliced (5mm-10mm), washed, color-protected for 10min-50min (0.5%NaCl+0.1%citric acid), blanched in the filling solution ( The mass fraction is 10% ~ 30% mixed filling liquid, maltodextrin mass: glucose = 3:1, 100 ° C, 3min ~ 6min), vacuum frying until the moisture content is about 30%, frying, deoiling conditions and examples 1 is the same. After deoiling, take it out for heat pump drying, heat pump drying conditions: drying temperature 30 ℃ ~ 60 ℃, drying time 4h ~ 8h. Re-seasoning (salt 0.5%, sugar 2%, I+G 0.01%, monosodium glutamate 0.2%) and packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com