Porous bracket with micro grooves on pore walls and preparation method thereof

A technology of porous scaffolds and micro-grooves, applied in medical science, prosthesis, etc., can solve the problem of difficulty in constructing micro-grooves, and achieve the advantages of large-scale production, good reproducibility, and good adhesion of cells. attached effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

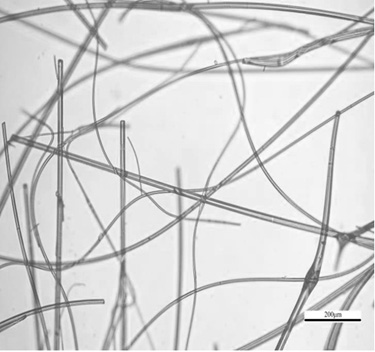

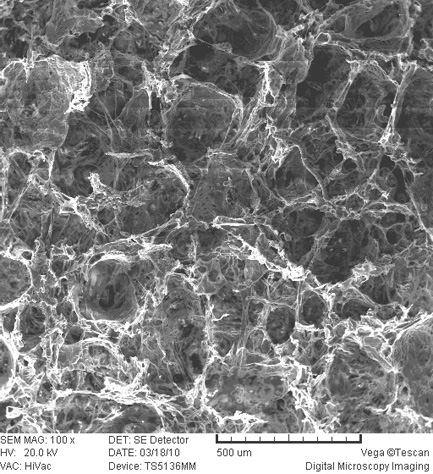

[0034] Firstly, the sugar fiber is spun by a commercially available electric drawing machine, with a diameter of 10 μm, and the sodium chloride is sieved with a molecular sieve to obtain different particle sizes, and the sodium chloride with a particle size of 180 μm-280 μm is taken for use. Dissolve 2g of PLGA85 / 15 with a molecular weight of 359,000 in 11g of dichloromethane, then evenly disperse 1g of sugar fiber and 30g of sodium chloride in the dichloromethane solution of PLGA, pour it into a mold, and press it at room temperature. After 24 hours Decompress, take out the support, soak the support with 200ml deionized water, change the water once every 1 hour, until the aqueous solution of 0.1mol / L silver nitrate is added dropwise in the leachate, no white precipitation occurs, indicating that sugar fibers and chlorine The sodium chloride has been completely leached, and the stent that has completely leached the porogen is sucked off most of the deionized water with filter p...

Embodiment 2

[0035] Example 2 Dissolve 2g of PLGA85 / 15 with a molecular weight of 359,000 in 11g of dichloromethane, then disperse 5g of sugar fiber (diameter 10μm) and 26g of sodium chloride (particle size 180μm-280μm) in the dichloromethane of PLGA Methane solution, poured into the mold, molded at room temperature, decompressed after 24 hours, used 200ml deionized water support, and changed the water every 0.5 hours until the aqueous solution of 0.1mol / L silver nitrate was added dropwise to the leaching solution. A white precipitate appears, indicating that the sugar fiber and sodium chloride have been completely leached, and the stent that has completely leached the porogen is sucked off most of the deionized water with filter paper or toilet paper, and then vacuum-dried at a drying temperature of 20°C and a drying time of 48 hours , to obtain a three-dimensional porous scaffold with a pore diameter of 200 μm and a porosity of 90% with grooves on the pore wall. The grooves are 10 μm wide...

Embodiment 3

[0036] Example 3 Dissolve 2g of PLGA85 / 15 with a molecular weight of 359,000 in 17g of dichloromethane, then disperse 1g of sugar fiber (diameter 15μm) and 20g of sodium chloride (particle size 180μm-280μm) in PLGA dichloromethane Methane solution, poured into the mold, molded at room temperature, decompressed after 24 hours, took out the bracket, soaked the bracket with 200ml deionized water, changed the water every 1 hour, until the aqueous solution of 0.1mol / L silver nitrate was used, dripping Add it to the leaching solution until no white precipitate appears. Use filter paper or toilet paper to absorb most of the deionized water from the scaffold that has completely leached the porogen, and then vacuum-dry it at a temperature of 20°C for 48 hours to obtain a pore wall belt with a pore size of 200 μm and a porosity of 86%. A three-dimensional porous scaffold with 15 μm wide and 15 μm deep grooves has a theoretical coverage of about 10% of the surface area of the pore wall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com