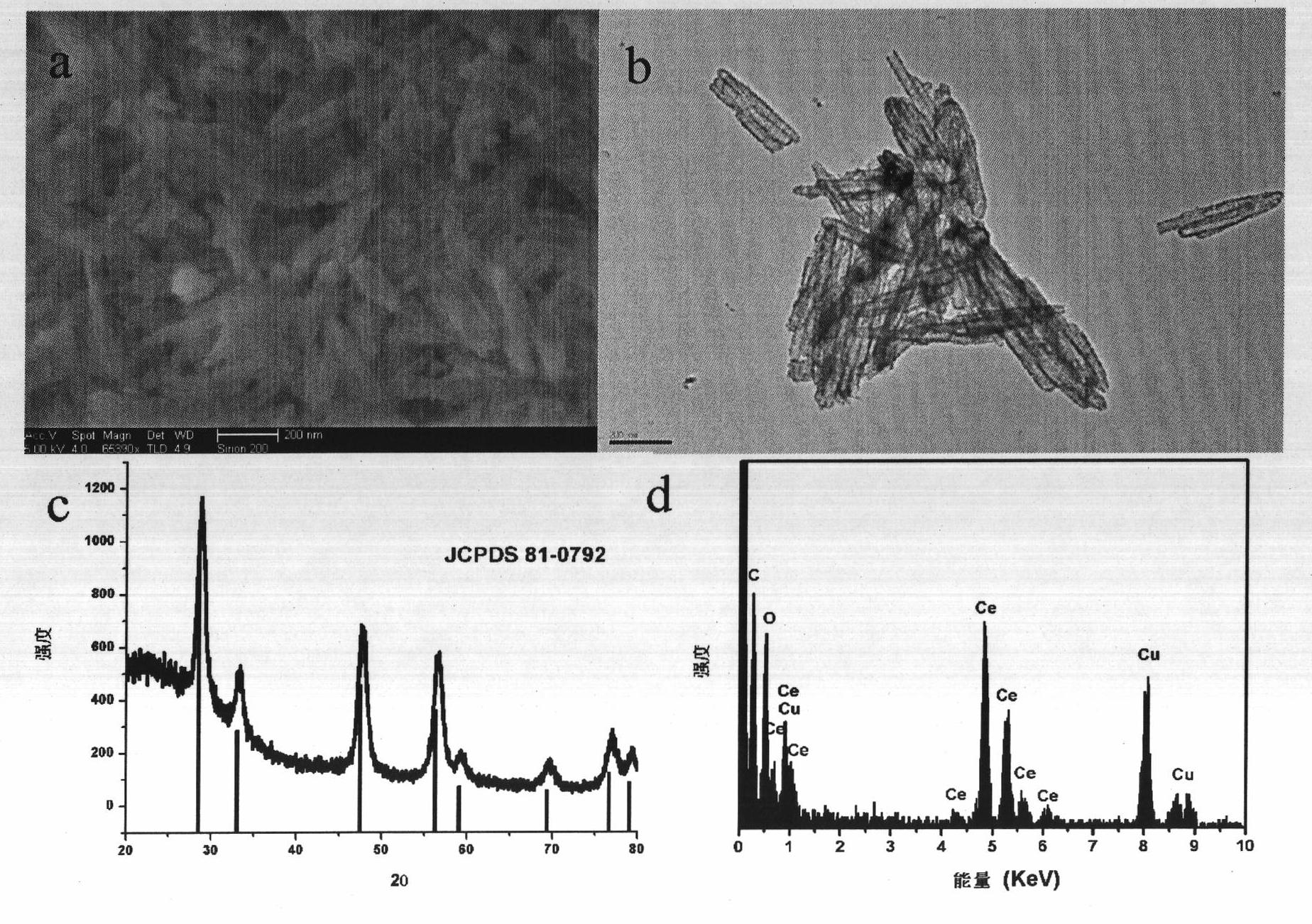

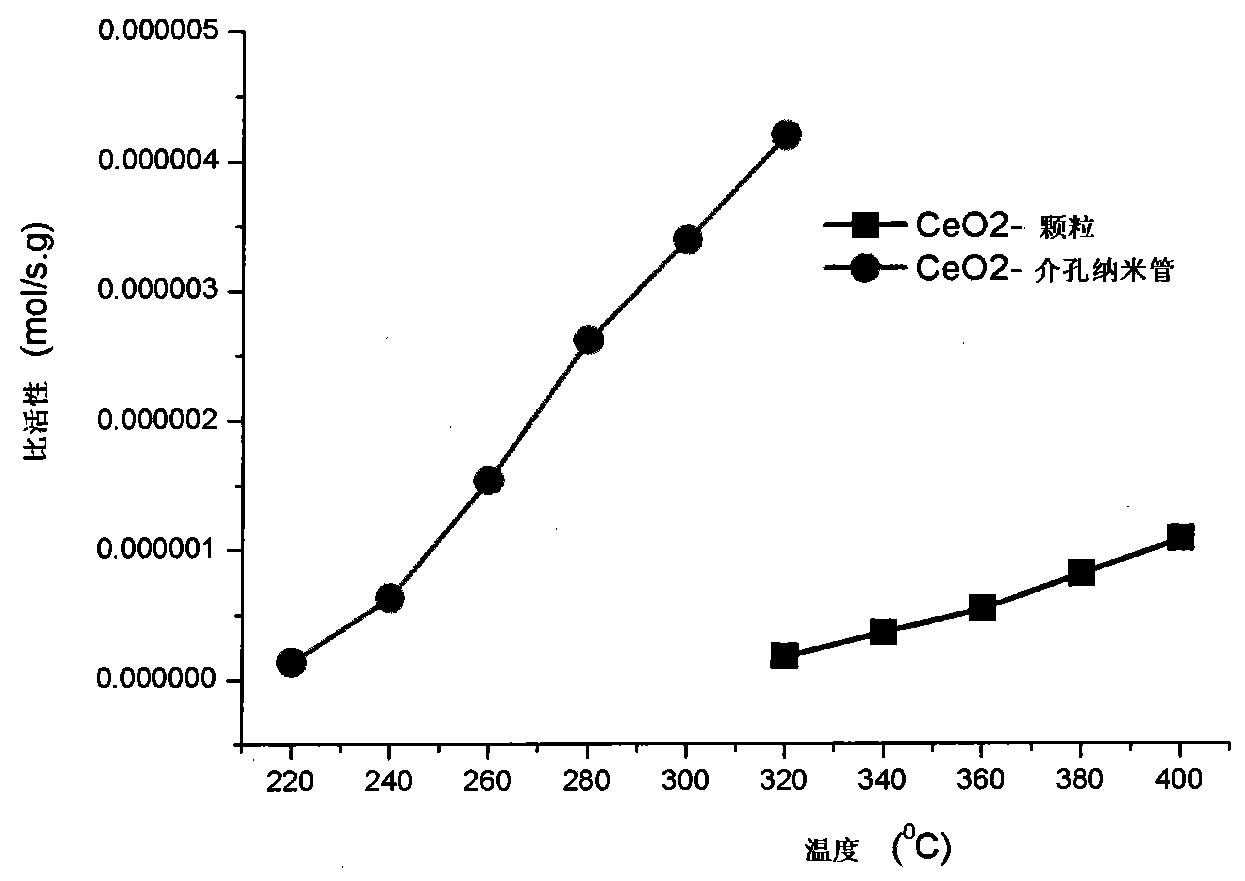

Method for preparing mesoporous CeO2 nano-tubes having large specific surface area and high catalytic activity

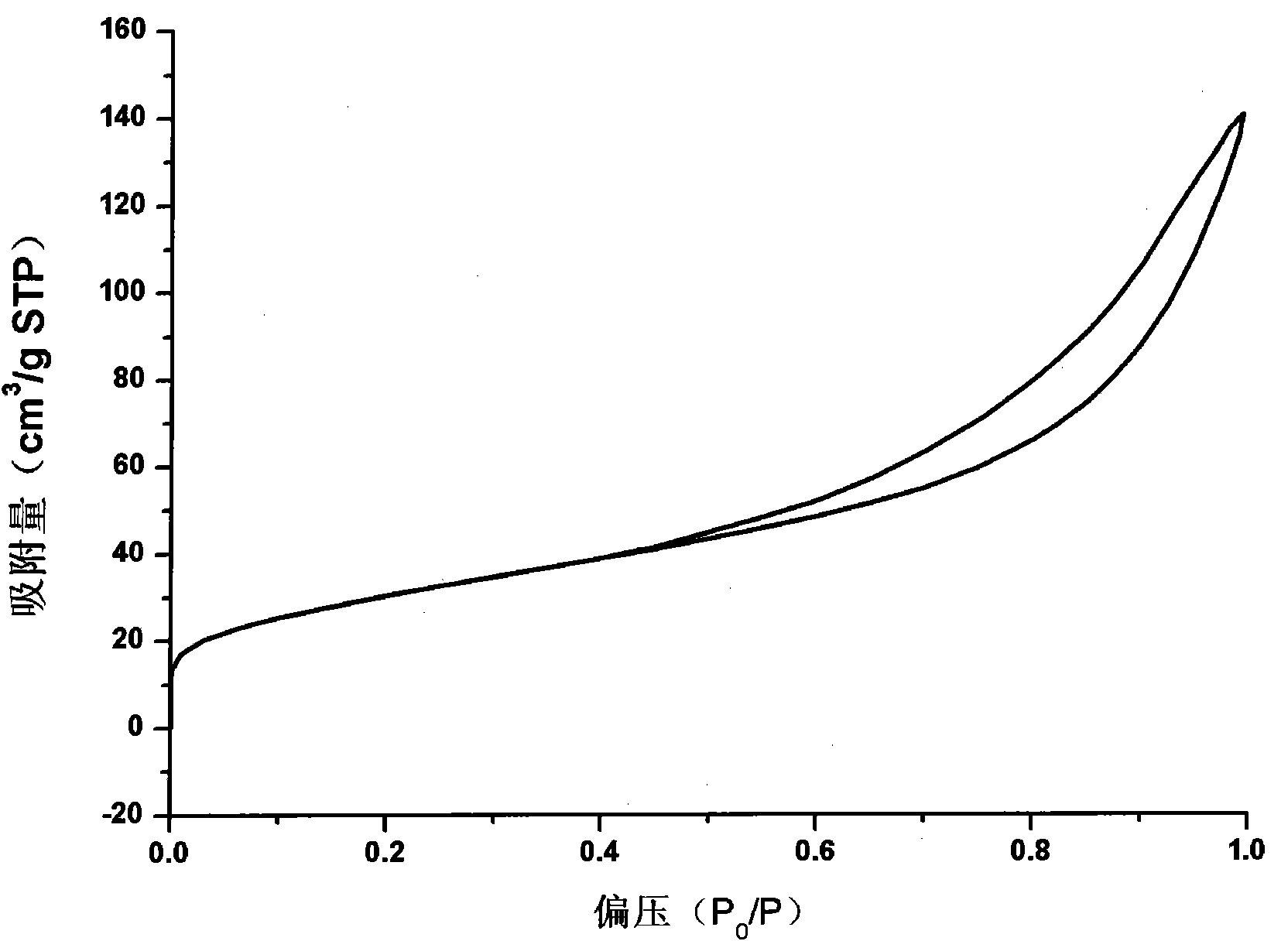

A technology with high catalytic activity and high specific surface area, applied in the field of preparation of mesoporous CeO2 nanotubes, can solve the problem of low specific surface area and achieve high catalytic activity and low light-off temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Raw materials: zinc acetate, cerium nitrate, sodium hydroxide, nitric acid, absolute ethanol, etc.

[0021] Preparation steps:

[0022] (1) Preparation of ZnO nanorods. ZnO nanorods with a diameter of about 20 nanometers and an aspect ratio of about 10 were synthesized by hydrothermal method. The specific process is: 15mL concentration is 0.1ML -1 The zinc acetate ethanol solution was added dropwise to 30mL with a concentration of 0.5ML -1 NaOH ethanol solution and stirred for 30 min. Then the mixed solution was transferred to a 60mL autoclave, and heated in an oven at 150-200°C for 24 hours. The reacted product was filtered several times with deionized water and then dried in air at 60°C;

[0023] (2) Preparation of ZnO / mesoporous CeO2 core-shell structure. On the basis of the obtained ZnO nanorods, the ZnO / mesoporous CeO was constructed by a continuous ion-layer adsorption reaction method. 2 Core shell structure. The specific process is as follows: First, put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com