Injectable bone repairing material and preparation method thereof

A bone repair and injection technology, applied in medical science, prosthesis, etc., can solve the problems of fast curing, slow biodegradation, and poor stability of bone repair materials, and achieve good biocompatibility, promote regeneration, and stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The specific preparation method includes the following steps:

[0038] 1) Use gamma rays to irradiate sodium alginate to obtain sodium alginate with an average molecular weight of 6000-20000, preferably with an average molecular weight of 6000-15000;

[0039] 2) A hydrochloric acid solution with a pH of 4-4.5 prepared with pure water and hydrochloric acid;

[0040] 3) Dissolve the sodium alginate prepared in step 1 in the hydrochloric acid solution prepared in step 2. The mass percentage of sodium alginate to the volume percentage of hydrochloric acid is preferably 0.5-1%, and a certain amount of adipic acid dihydrazide ( adipic dihydrazide, abbreviated as ADH), the mass percentage concentration of ADH is 0.5-20%, and the ratio of ADH to alginic acid sugar units is preferably 1:1-1:5, preferably, the mass ratio of sodium alginate to ADH is 1 :15-1:20;

[0041] 4) Combine a certain quality of 1-ethyl-3-(3-dimethylaminopropyl)carbodiimide hydrochloride (EDC) and 1-hydroxybenzotr...

Embodiment 1

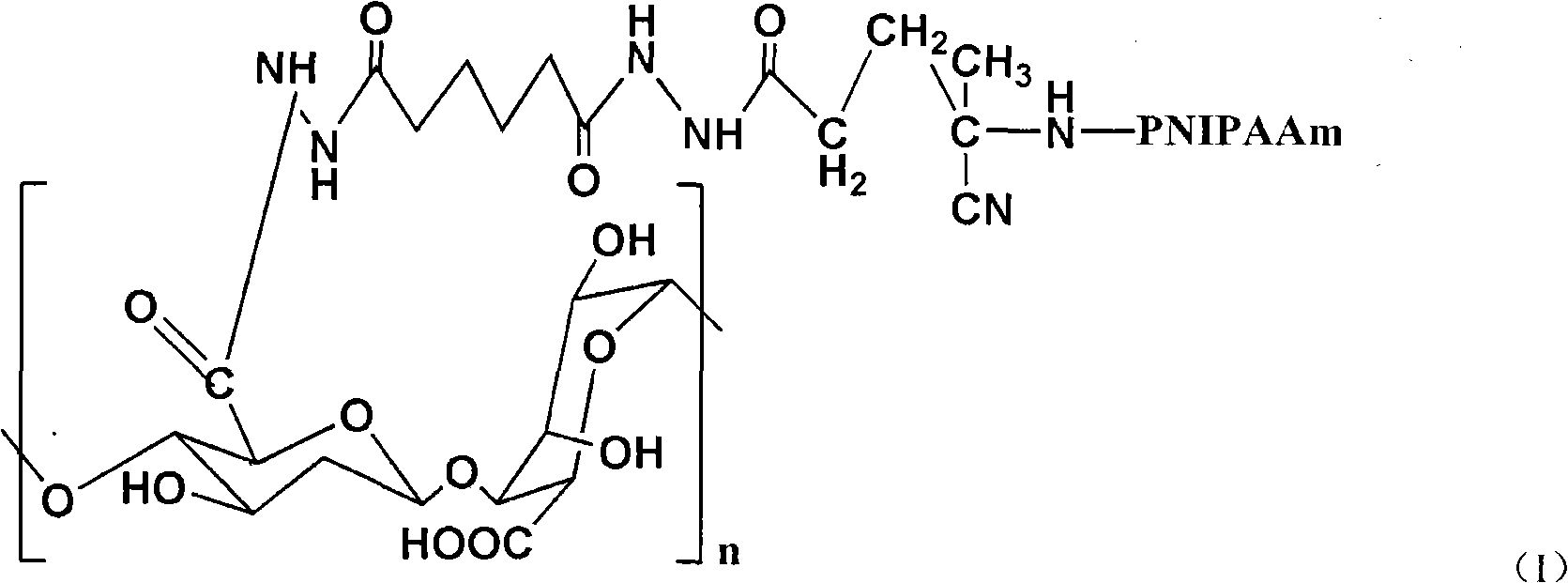

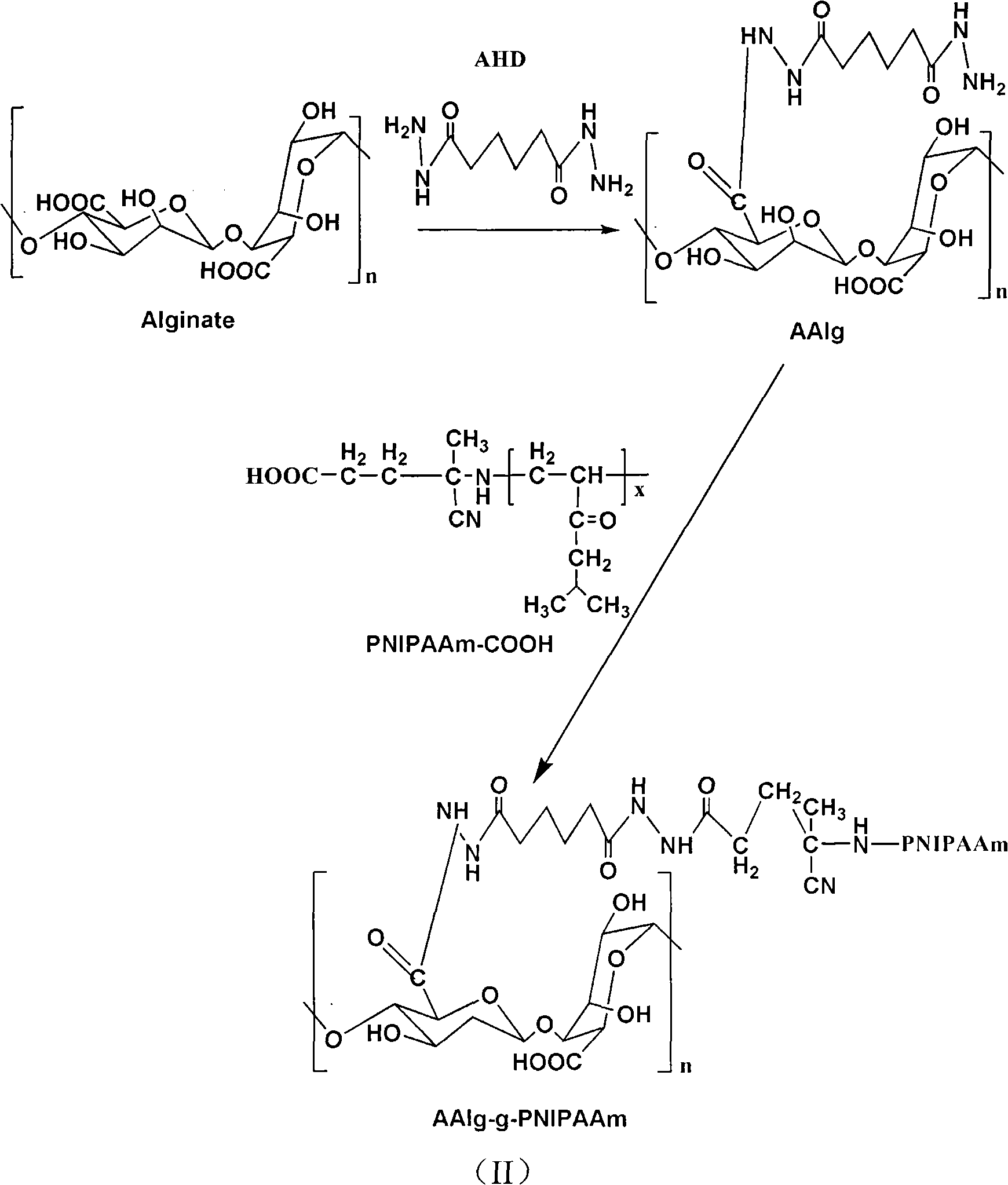

[0059] First, prepare AAlg-g-PNIPAAm of formula (I) according to reaction formula (II), and the specific preparation method is as follows:

[0060] 1) Use gamma rays to irradiate sodium alginate to obtain low molecular weight sodium alginate with an average molecular weight of 6000-8000;

[0061] 2) A hydrochloric acid solution with a pH of 4-4.5 prepared with pure water and hydrochloric acid;

[0062] 3) Dissolve 1 g of sodium alginate prepared in step 1 in 100 ml of hydrochloric acid solution prepared in step 2, and add 15 g of ADH after complete dissolution;

[0063] 4) Dissolve 1.6g EDC and 1.4g HOBt in dimethyl sulfoxide (DMSO) / water solution, the concentration of EDC and HOBt are 10mmol / ml respectively, the ratio of DMSO and water is 1:1, add this solution to In the mixed solution of step 3, stir and react at room temperature for 24 hours;

[0064] 5) Dialysis the reaction solution of step 4 in pure water for 3 days, the molecular weight of the dialysis bag semipermeable membrane...

Embodiment 2

[0072] First, prepare AAlg-g-PNIPAAm of formula (I) according to reaction formula (II), and the specific preparation method is as follows:

[0073] 1) Use gamma rays to irradiate sodium alginate to obtain low molecular weight sodium alginate with an average molecular weight of 6000-8000;

[0074] 2) A hydrochloric acid solution with a pH of 4-4.5 prepared with pure water and hydrochloric acid;

[0075] 3) Dissolve 0.5 g of sodium alginate prepared in step 1 in the 100 ml hydrochloric acid solution prepared in step 2, and add 10 g of ADH after it is completely dissolved;

[0076] 4) Dissolve 0.8g EDC and 0.7g HOBt in DMSO / water solution, where the ratio of DMSO to water is 1:1, add the solution to the mixed solution in step 3, and stir for 24 hours at room temperature;

[0077] 5) Dialysis the reaction solution of step 4 in pure water for 3 days, the molecular weight of the dialysis bag semipermeable membrane can dialyze out is 6000, then take out the dialysis solution, add a certain amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com