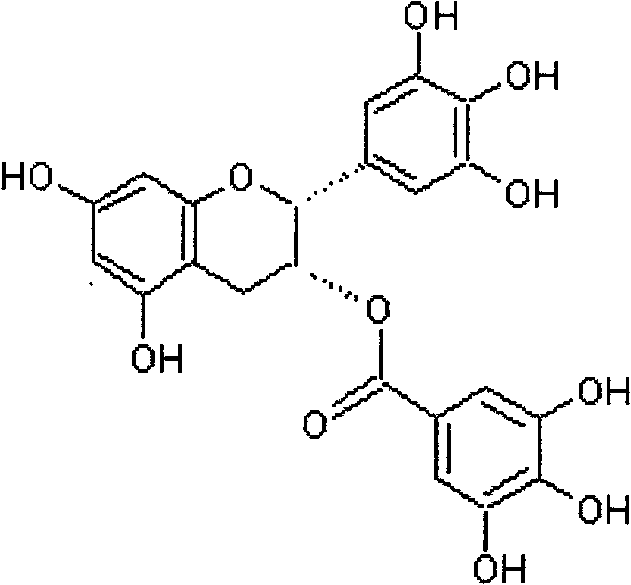

(-)-Epigallocatechin-3-gallate pill composition and application thereof

A technology of epigallocatechin and gallate, applied in the field of (-)-epigallocatechin gallate pill composition and its application, can solve the EGCG pill combination that has not been seen in the prevention and treatment of senile dementia To avoid problems such as drug patents, to avoid excessive local drug concentration, reduce irritation, and achieve good absorption reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1E

[0084] The preparation of embodiment 1EGCG pellet capsule

[0085] Prescription: EGCG 100g, microcrystalline cellulose 50g, HPMC 5g, sodium dihydrogen phosphate 0.5g, preparation method: take the above auxiliary materials, mix and sieve, add an appropriate amount of 75% ethanol to make a soft material, adjust the dry humidity of the soft material, and extrude In the machine, the diameter of the mesh is 0.5 mm, and the rotation speed is 10 r / min. Extrude the strip-shaped soft material and place it in a ball rolling machine to make a round ball to obtain wet pellets, and dry them with hot air at 50 ° C to obtain the final product.

[0086] Take the pellets and put them in the coating pot, add about 1kg of special-shaped blank pills to the coating pot, and coat them with 8% Opadry OY-C-700A ethanol solution, the speed of the coating pot is 5 rpm, the temperature of the pellet bed 40-43°C, control hot air temperature and proper spraying speed, keep the surface of the pills dry in ...

Embodiment 2

[0087] The preparation of embodiment 2EGCG pellets

[0088] Prescription: EGCG 100g, microcrystalline cellulose 50g, starch 50g, talcum powder 10g, HPMC 10g, diacetic acid 0.1g, preparation method: take diacetic acid and add a small amount of water to dissolve, absorb with talcum powder, dry, sieve, add EGCG, micro Mix crystalline cellulose, starch, HPMC, etc., put it in a rotary rolling pellet machine, spray 75% ethanol while adding powder, and rotate and roll granulate at a speed of 100r / min, take out the pellets, and place them in an oven with hot air at 60-65°C Dry and serve.

[0089] Take the pellets and put them into the coating pot, spray the coating solution (coating ingredients: 2.8g cellulose acetate, 0.625g ethyl cellulose, add dichloromethane and ethanol compound Solvent (100ml) appropriate amount, until the surface is moist, dry with hot air at 60-80°C, repeat the above operation until the coating weight increases by more than 10%, pack into bags, each bag is 1g,...

Embodiment 3

[0090] The preparation of embodiment 3EGCG pill

[0091] Prescription: EGCG 200g, microcrystalline cellulose 100g, lactose 50g, aspartic acid 1.0g.

[0092] Preparation method: Take the above auxiliary materials, mix and sieve, add 75% ethanol to make soft material, adjust the dry humidity of the soft material, put it in the extruder, the mesh diameter is 3mm, the speed is 10r / min, extrude the soft material in strip shape Roll into a ball in a ball rolling machine to obtain small wet pellets, and dry them with hot air at 50°C.

[0093] Take the dried pellets, put them in a coating pan, and coat them with 8% Opadry OY-C-700A ethanol solution, the coating pan rotates at 5 rpm, the pellet bed temperature is 40-43°C, and the hot air temperature and appropriate temperature are controlled. Spray quickly, keep the surface of the pills dry in time, coat for about 3 hours, increase the weight of the pills by about 10%, and contain 500mg of EGCG per gram.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com