Method for synthesizing graphene

A graphene and halogenated hydrocarbon technology, applied in the field of chemical synthesis, can solve the problems of complex operation, low controllability, difficult to mass-produce, etc., and achieve the effects of high purity, avoidance of damage, and complete flakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Weigh 18.6g of ferrocene and 18.1g of 1,2,4-trichlorobenzene in a molar ratio of 1:1, add them into a high temperature and high pressure reactor and stir evenly. After sealing, raise the temperature to 500°C under nitrogen atmosphere, and keep it warm for 0.1h. The resulting product was washed repeatedly with acetone to remove unreacted ferrocene and generated amorphous carbon and other small molecular substances. Then wash repeatedly with 0.5mol / l dilute hydrochloric acid to remove residual metal and metal chloride impurities, and finally wash with deionized water until the filtrate is neutral, and dry in a common oven at 100°C to obtain graphene.

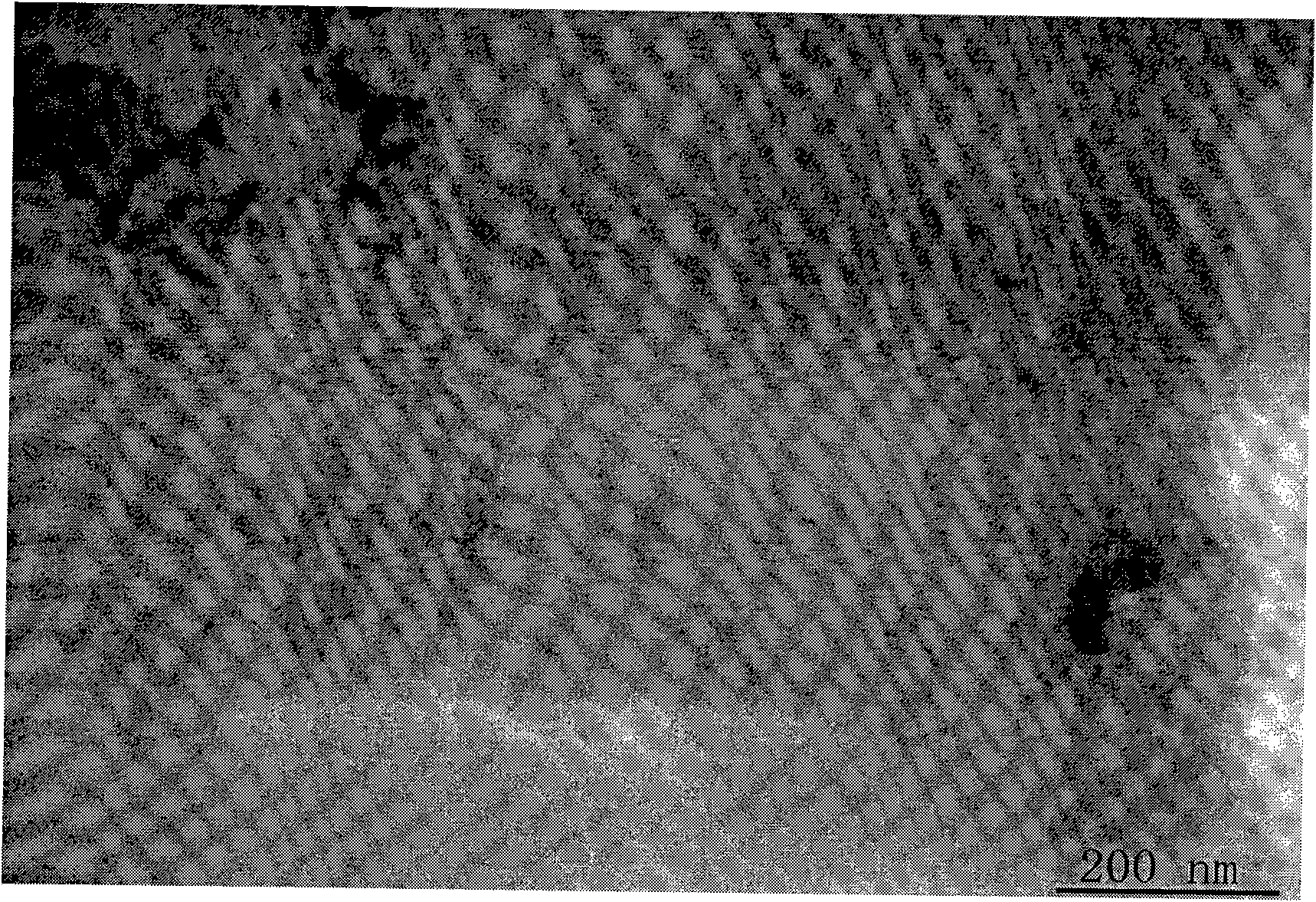

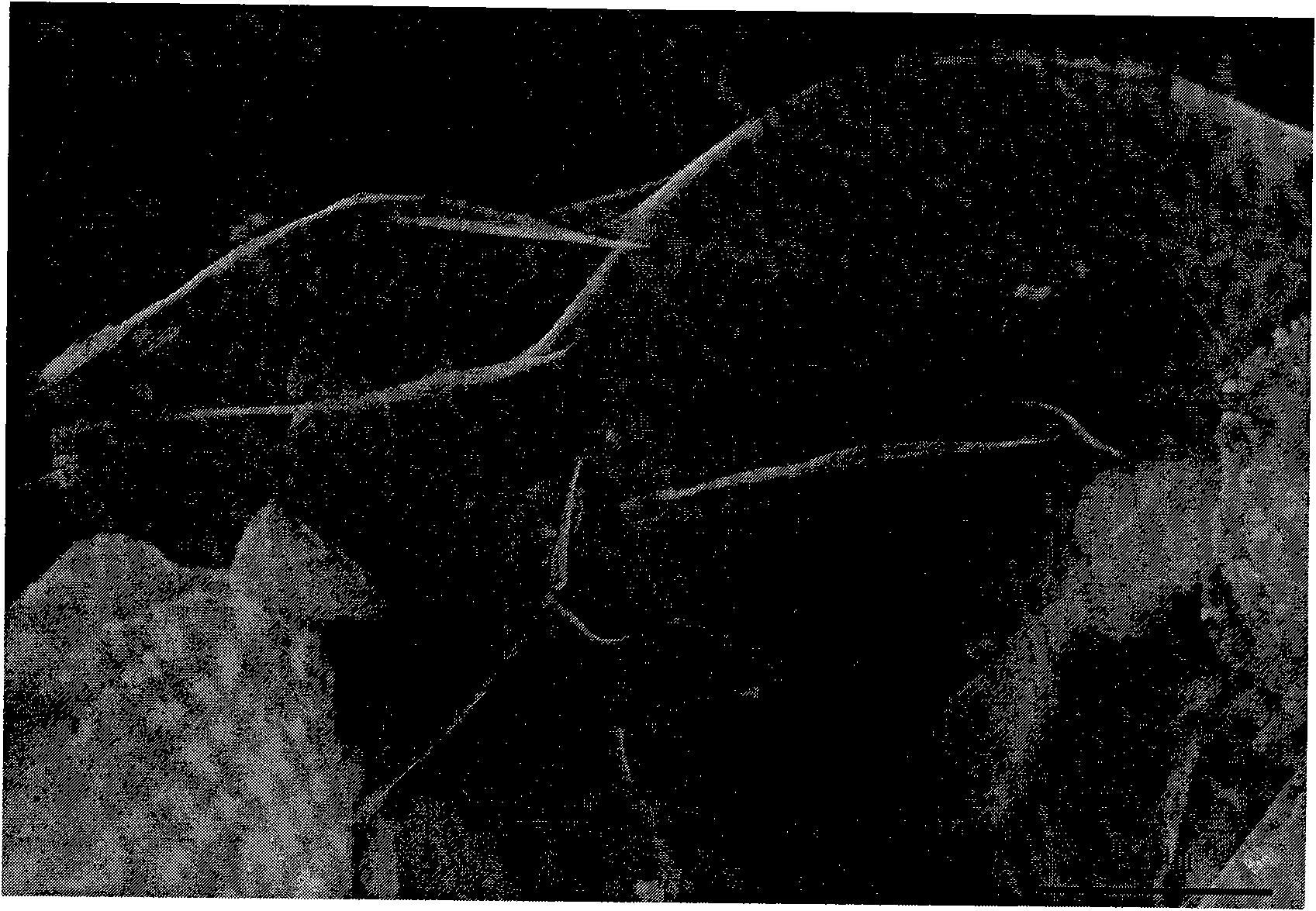

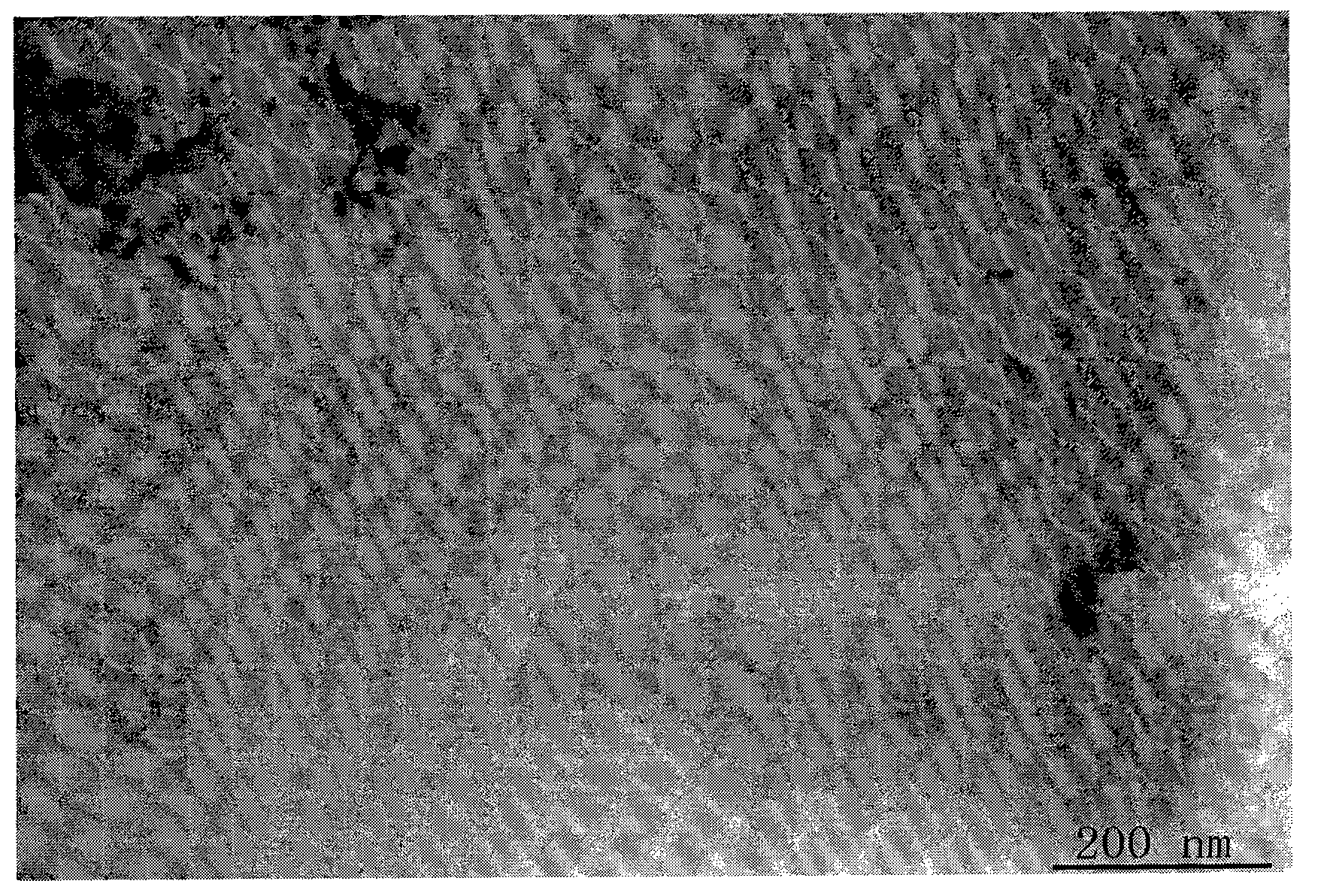

[0020] as attached figure 1 As shown by transmission electron microscopy (TEM), the prepared graphene is in the form of sheets with a length of 1-2 μm. as attached figure 2 As shown by a scanning electron microscope (SEM), the thickness of the prepared graphene is 3-5 nm.

Embodiment 2

[0022] Weigh 1.9 g of cobaltocene and 15.4 g of carbon tetrachloride in a molar ratio of 0.1:1, add them into a high-temperature and high-pressure reactor and stir evenly. After sealing, raise the temperature to 460°C in an argon atmosphere and keep it warm for 2 hours. The resulting product was washed repeatedly with absolute ethanol to remove unreacted cobaltocene and generated amorphous carbon and other small molecular substances. Then wash repeatedly with 0.1mol / l dilute sulfuric acid to remove residual metal and metal chloride impurities, and finally wash with deionized water until the filtrate is neutral, and dry in a common oven at 100°C to obtain graphene.

Embodiment 3

[0024] 18.9 g of nickelocene and 3.4 g of tetrabromoethylene were weighed in a molar ratio of 10:1, added to a high-temperature and high-pressure reactor and stirred evenly. After sealing, the temperature was raised to 520° C. under a nitrogen atmosphere, and the temperature was kept for 4 hours to obtain graphene. The generated graphene was washed repeatedly with pyridine to remove small molecular substances such as unreacted nickelocene and generated amorphous carbon. Then wash it repeatedly with 0.3mol / l dilute nitric acid to remove residual metal and metal chloride impurities, and finally wash it with deionized water until the filtrate is neutral, and dry it in a common oven at 100°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com