Method for preparing bionic modified collagen tissue repair material

A collagen tissue and repair material technology, applied in tissue regeneration, coating, medical science, etc., can solve the problems of lower material quality, repair effect, poor biocompatibility, etc., achieve low cost, facilitate large-scale production, and simple molding process effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of a biomimetic modified collagen tissue repair material, the steps are as follows:

[0030] (1) Prepare a collagen-acetic acid solution of 7mg / ml with a 3% volume fraction of acetic acid for type I collagen;

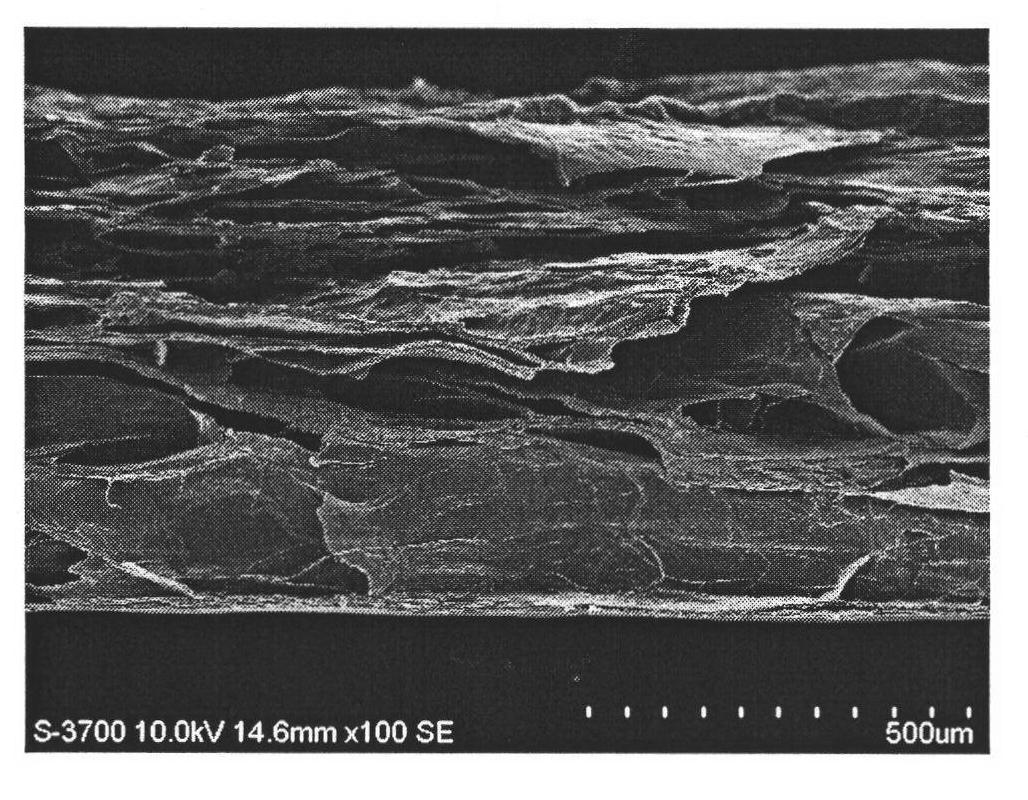

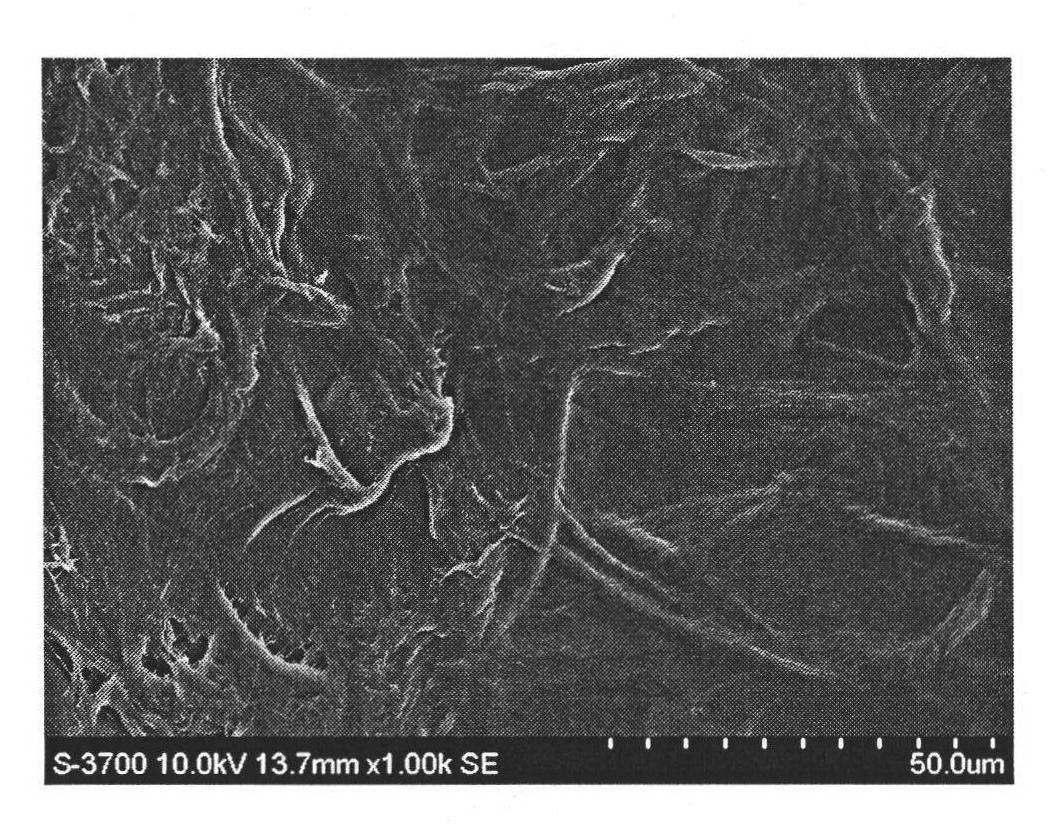

[0031] (2) Cast the collagen-acetic acid solution in step (1) into a plastic mold, pre-freeze at -60°C for one day (24 hours), and freeze-dry at -80°C in vacuum to obtain a collagen sponge of 55mm×15mm×12mm;

[0032] (3) Place the freeze-dried collagen sponge in step (2) in a vacuum drying oven, and conduct a vacuum thermal crosslinking reaction at 120°C for 24 hours. After stopping heating, keep the vacuum state and cool to room temperature before taking out the sample;

[0033] (4) The collagen sponge after thermal cross-linking is soaked in a mixed solution of EDC and NHS at 4° C. for 12 hours to promote further chemical cross-linking. The concentration of EDC in this mixed solution is 14mM, the concentration of NHS is 5.6mM, and the molar ratio...

Embodiment 2

[0039] The preparation method of a biomimetic modified collagen tissue repair material, the steps are as follows:

[0040] (1) Prepare type I collagen with 3% acetic acid solution to make 5mg / ml collagen solution;

[0041] (2) Cast the collagen-acetic acid solution in step (1) into a plastic mold, pre-freeze at -60°C for one day, and freeze-dry in vacuum at -80°C for 48 hours to obtain a collagen sponge with a size of 55mm×15mm×15mm;

[0042] (3) Place the freeze-dried collagen sponge in step (2) in a vacuum drying oven, and conduct a vacuum thermal cross-linking reaction at 100° C. for 24 hours. After stopping heating, keep the vacuum state and cool to room temperature before taking out the sample;

[0043] (4) The thermally crosslinked collagen sponge is soaked in a mixed solution of EDC and NHS at 4°C for 12 hours. The concentration of EDC is 12mM and the concentration of NHS is 4.8mM. After cross-linking, discard the EDC-NHS solution, rinse with deionization 10 times, pre-freeze...

Embodiment 3

[0048] The preparation method of a biomimetic modified collagen tissue repair material, the steps are as follows:

[0049] (1) Prepare type I collagen with a 3% acetic acid solution to prepare a 6mg / ml collagen-acetic acid solution, and add bioactive glass powder, where the mass ratio of bioactive glass to collagen is 1:4;

[0050] (2) Cast the collagen-acetic acid solution in step (1) into a plastic mold, pre-freeze at -60°C for one day, and freeze-dry in vacuum at -80°C to obtain a collagen sponge of 55mm×15mm×12mm;

[0051] (3) Place the freeze-dried collagen sponge in step (2) in a vacuum drying oven, heat the crosslinking reaction in a vacuum at 110°C for 24 hours, stop heating and then keep the vacuum state and cool to room temperature before taking out the sample;

[0052] (4) The collagen sponge after thermal crosslinking is soaked in a 0.25% (mass fraction) glutaraldehyde solution at 4°C for 4 hours. After cross-linking, discard the glutaraldehyde solution, rinse with deioniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com