Photoetching manufacturing process

A production process and photolithography technology, applied in the field of photolithography and etching production process, can solve problems such as photoresist peeling off, achieve the effect of improving wafer yield and preventing acid tank pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The photolithography manufacturing process of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

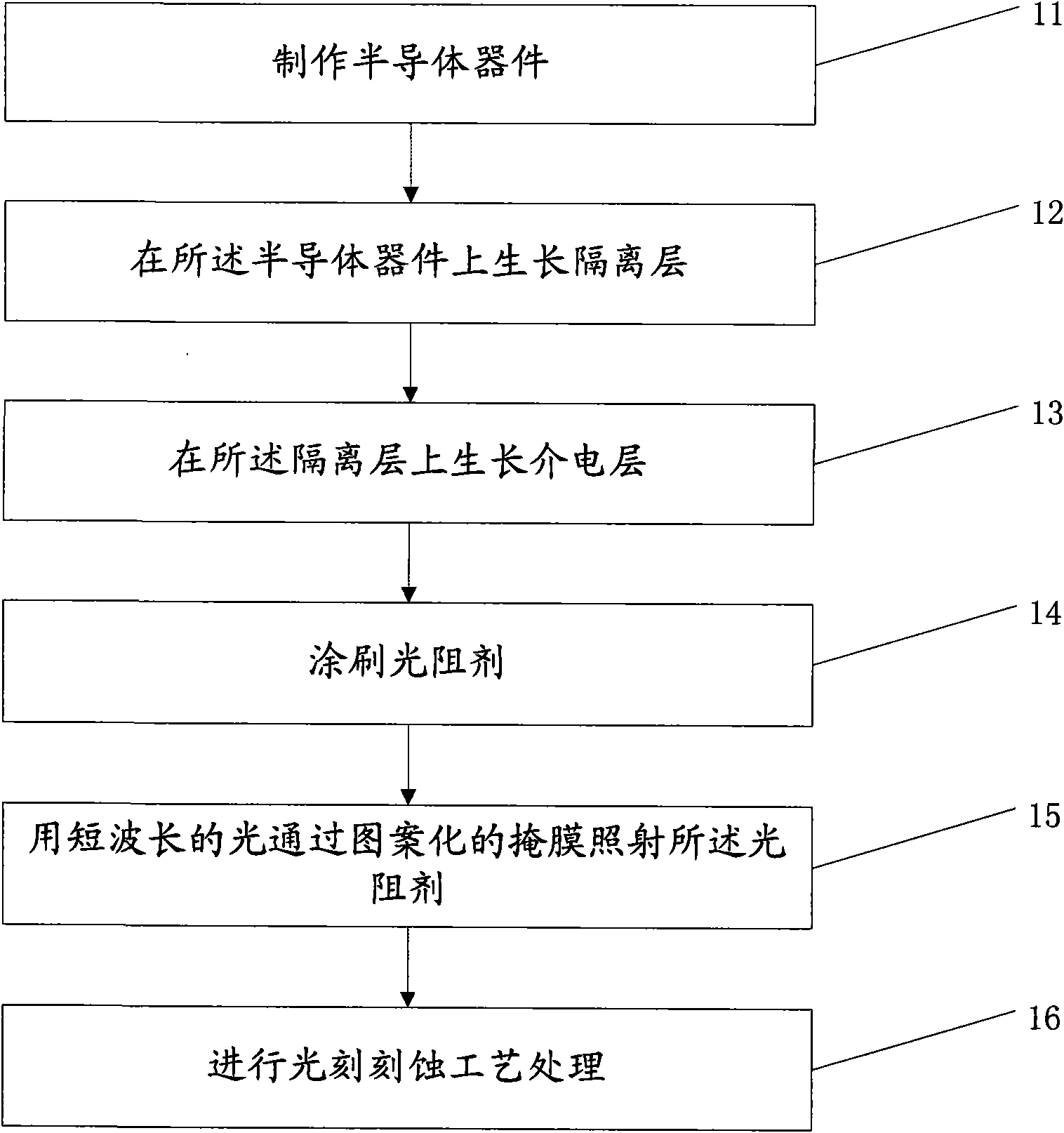

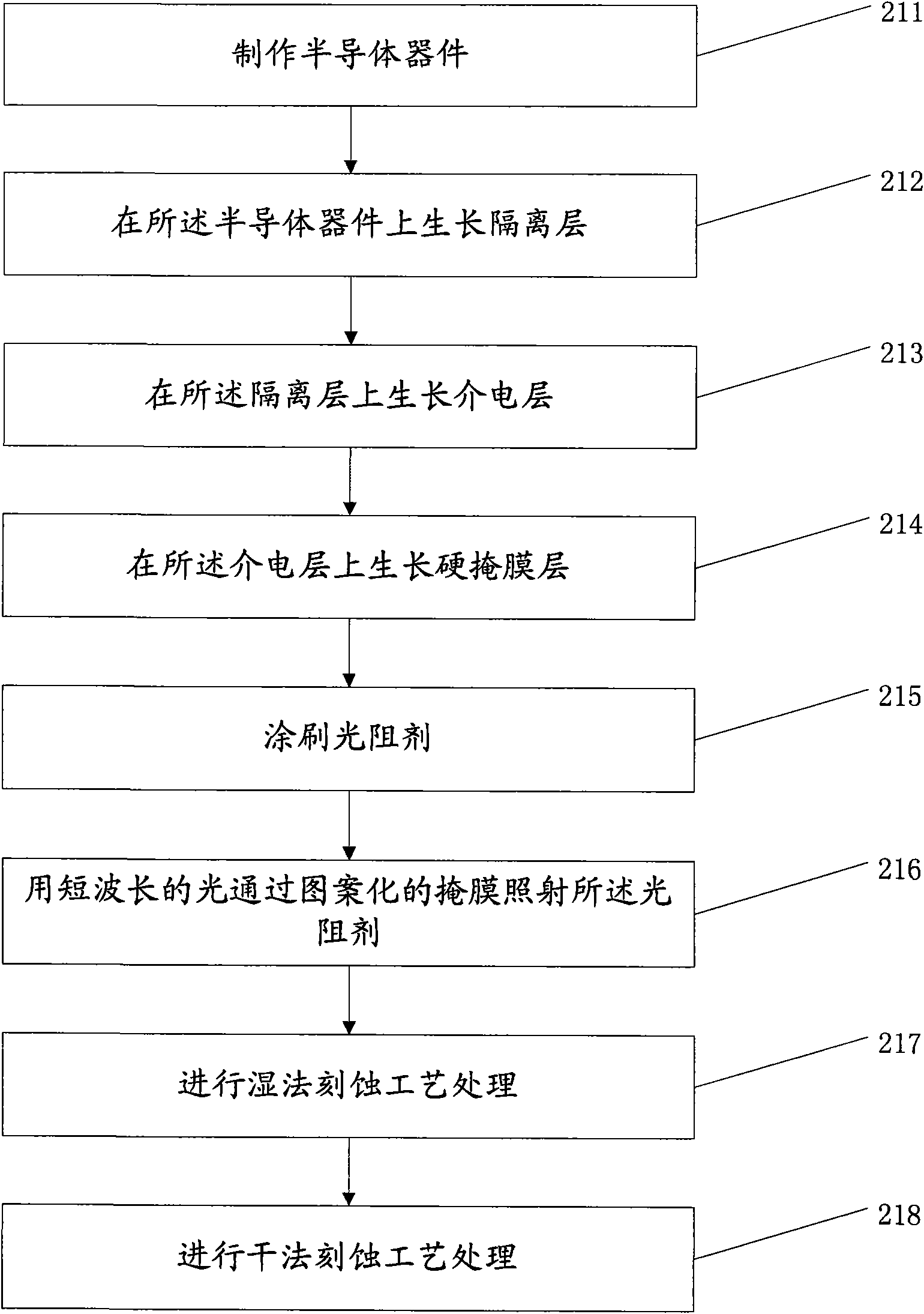

[0017] First, please refer to figure 2 , figure 2 It is a flow chart of the etching process of the present invention, including the following steps: Step 211: making a semiconductor device, including a series of processes such as film growth, etching, ion implantation and cutting on the wafer, until the semiconductor device is formed, according to different devices Types, using different manufacturing processes, not described one by one here; step 212: growing an isolation layer on the semiconductor device, the isolation layer material is ethyl silicate (TEOS), the function of the isolation layer is to The dielectric layer to be grown is isolated from the semiconductor device, because the dielectric layer generally contains boron and phosphorus, which are impurities relative to the semi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com