Method for modularizing crystal and heat sink in laser diode pumped solid laser

A technology of laser diodes and solid-state lasers, which is applied to lasers, laser components, laser components, etc., can solve problems such as the difficulty of effective heat dissipation of crystals, improve reliability and environmental adaptability, reduce assembly difficulty, and weaken thermal effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

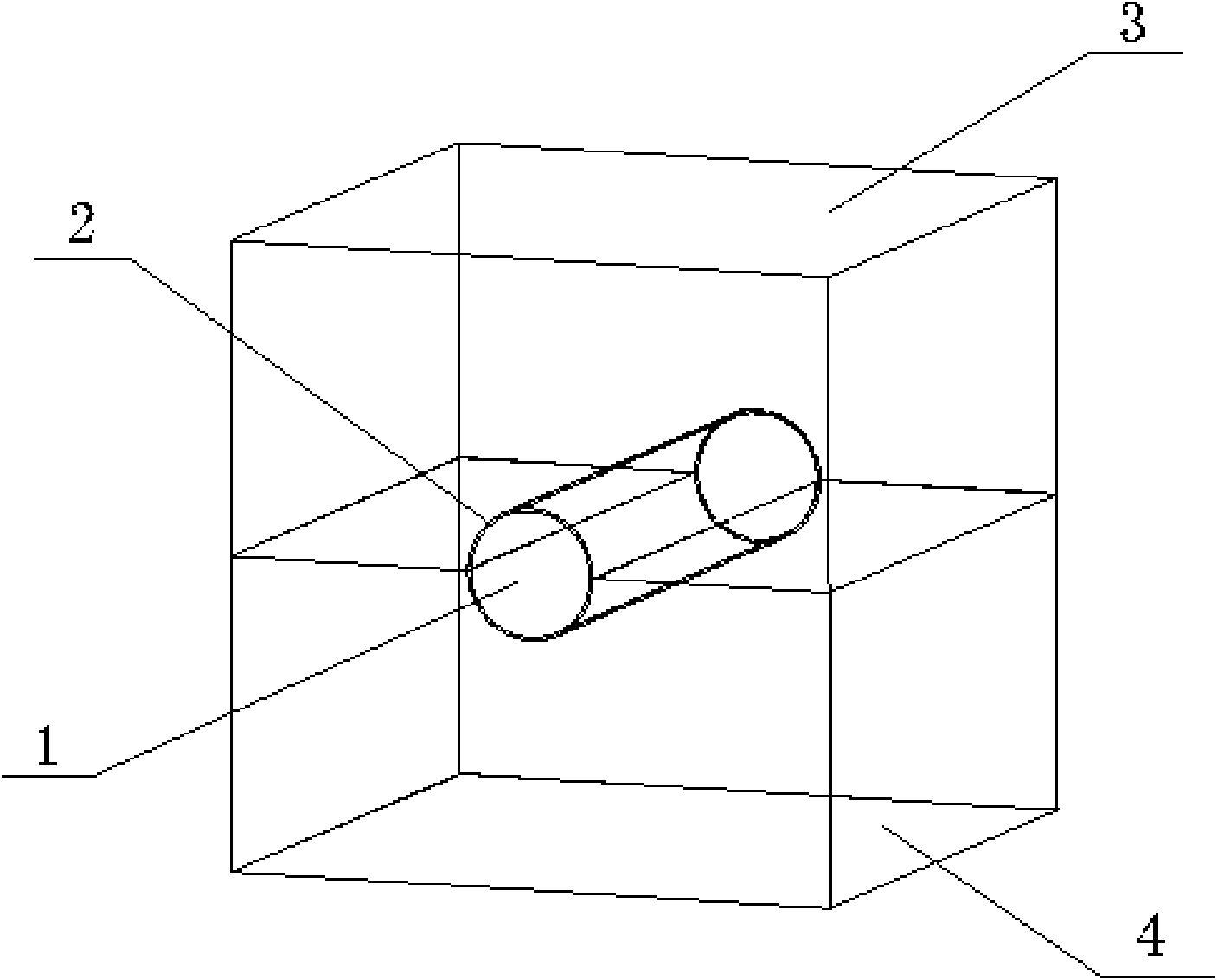

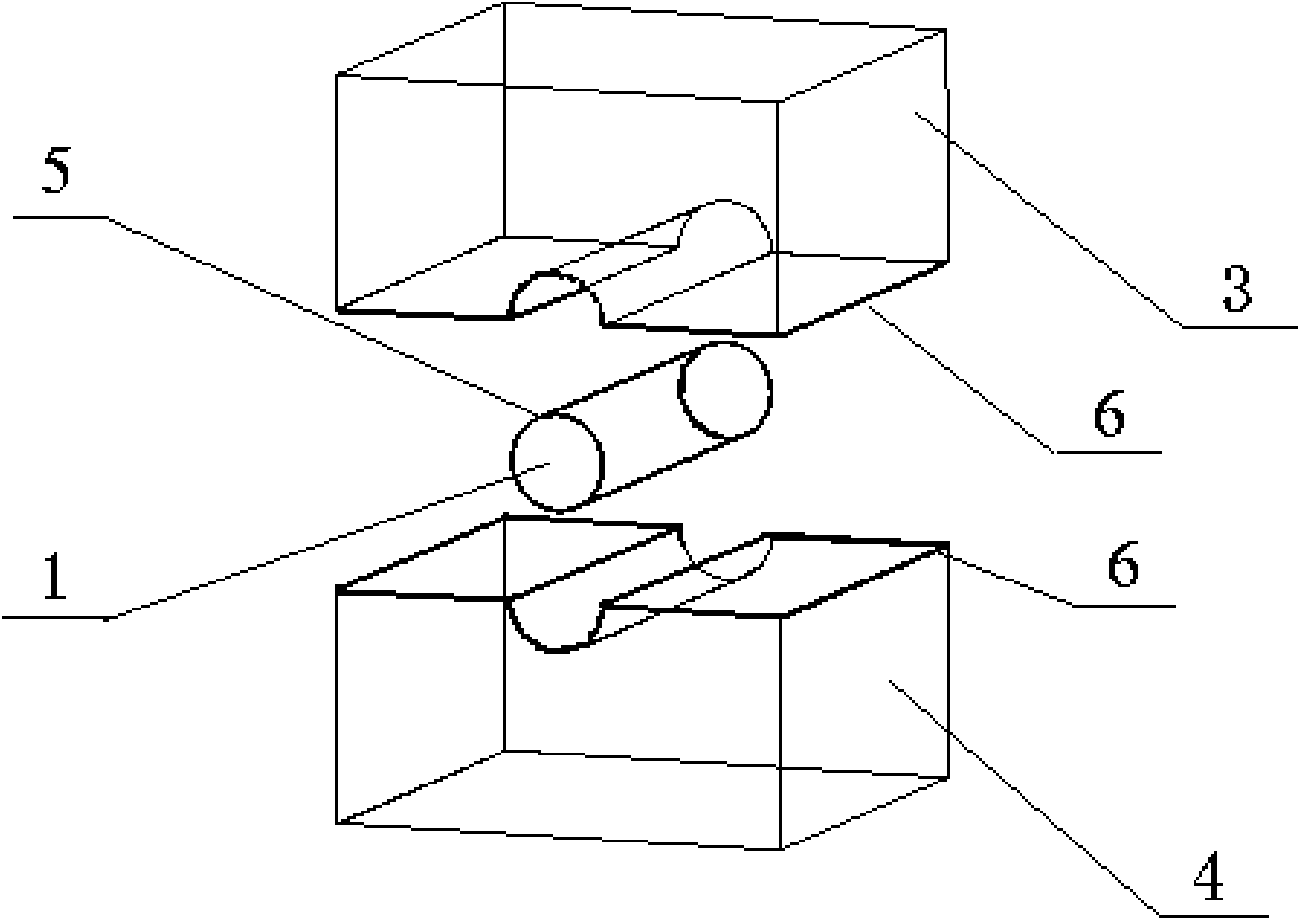

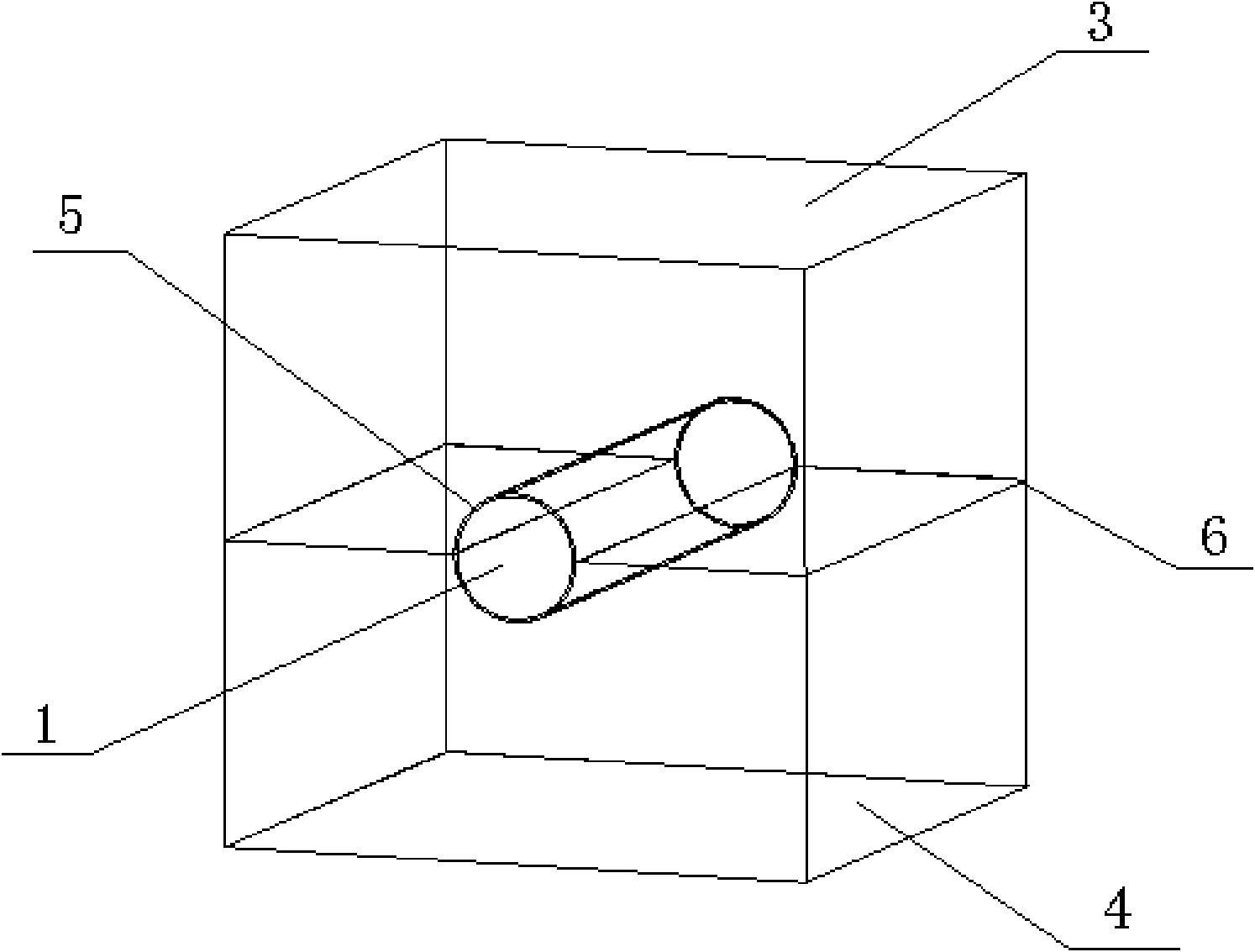

[0016] figure 2 In the schematic diagram of the embodiment shown, the crystal 1 is a non-coated crystal on the end face (because the crystal coating will affect the coating effect during the sintering process, or the coating will be burned, so the crystal 1 is a non-coated crystal on the end face, and finally the welded crystal and the crystal are heated sink the overall coating to obtain an integrated component that can be used directly.) The gold powder layer 5 with a thickness of about 5 microns is sintered on the side; the crystal heat sink upper assembly 3 and the crystal heat sink lower assembly 4 are processed from oxygen-free copper materials, and The crystal heat sink upper component 3 and the crystal heat sink lower component 4 are electroplated with a silver layer 6 with a thickness of about 15 microns on the connection surface of the crystal 1, and the silver layer 6 is mainly used as solder; the crystal 1 and the crystal heat sink after burning gold The upper com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com