Novel silicon carbide ceramic and preparation method thereof

A silicon carbide ceramic and silicon carbide technology are applied in the field of new silicon carbide ceramics and their preparation, which can solve the problems of free silicon and high production costs in ceramics, and achieve the effects of reducing the pressure of processing waste, saving resources and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

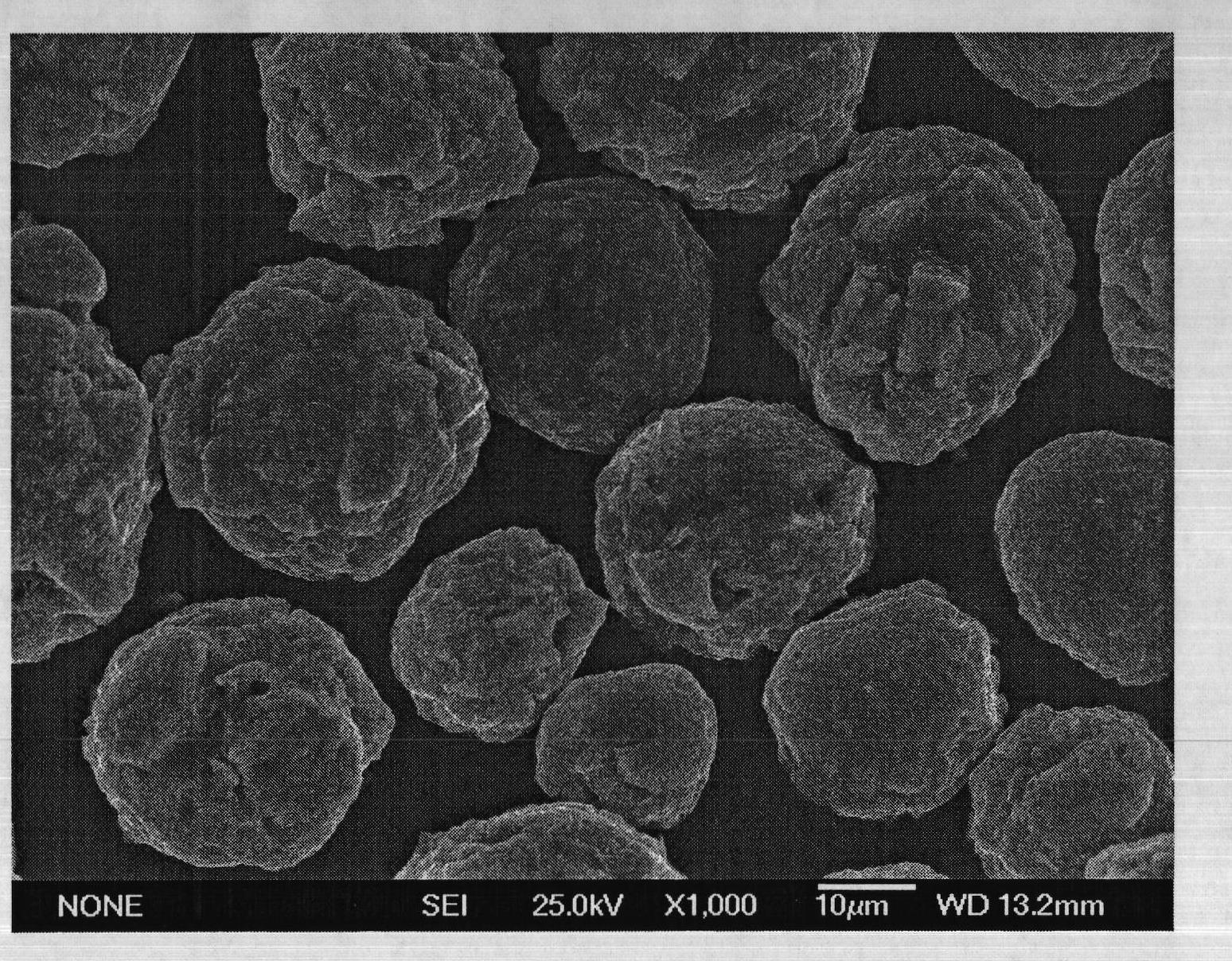

Image

Examples

Embodiment 1

[0026] Embodiment 1: A kind of novel silicon carbide ceramics, the mass percent of its main material is composed of: 80% silicon carbide powder, 10% silicon powder and 10% carbon powder, and its auxiliary material is polyvinyl alcohol and polyethylene glycol, polyethylene The consumption of alcohol is 1% of the main material gross mass, and the total mass of polyethylene glycol is 0.5% of the main material gross mass;

[0027] Carry out the following steps in sequence during preparation:

[0028] (1) Prepare silicon carbide powder, a. Soak the silicon carbide waste material with an acid solution with a pH of 1 for 8 hours to remove metal and oxide impurities, and then soak with an alkaline solution with a pH of 11 for 2 hours to remove silicon dioxide; B, disperse the product of step a in water of 0.8 times its mass to form a suspension, adjust the pH of the suspension to 2, stir for 6 hours, filter, wash the filter cake with water until the washing liquid is neutral, and dry ...

Embodiment 2

[0034] Embodiment 2: A kind of novel silicon carbide ceramics, the mass percent of its main material is composed of: 90% silicon carbide powder, 6% silicon powder and 4% carbon powder, and its auxiliary material is carboxymethyl cellulose and tetramethyl hydrogen Ammonium oxide, the amount of carboxymethyl cellulose is 5% of the total mass of the main ingredients, and the total mass of tetramethylammonium hydroxide is 1% of the total mass of the main ingredients;

[0035] Carry out the following steps in sequence during preparation:

[0036] (1) Prepare silicon carbide powder, a. Soak the silicon carbide waste material in an acid solution with a pH of 3 for 9 hours to remove metal and oxide impurities, and then soak in an alkaline solution with a pH of 12 for 3 hours to remove silicon dioxide; B, disperse the product of step a in water of 0.9 times its mass to form a suspension, adjust the pH of the suspension to 1, stir for 12 hours, filter, wash the filter cake with water un...

Embodiment 3

[0042] Embodiment 3: A kind of novel silicon carbide ceramics, the mass percent of its main material is composed of: 85% silicon carbide powder, 8% silicon powder and 7% carbon powder, and its auxiliary material is polyvinyl alcohol and carboxymethyl cellulose Mixture and aluminophosphate, the amount of the mixture of polyvinyl alcohol and carboxymethyl cellulose is 3% of the total mass of the main material, and the total mass of aluminophosphate is 1% of the total mass of the main material;

[0043] Carry out the following steps in sequence during preparation:

[0044] (1) Prepare silicon carbide powder, a. Soak the silicon carbide waste material in an acid solution with a pH of 5 for 10 hours to remove metal and oxide impurities, and then soak in an alkaline solution with a pH of 13 for 4 hours to remove silicon dioxide; b. Disperse the product of step a in water of 1 times its mass to form a suspension, adjust the pH of the suspension to 1.5, stir for 14 hours, filter, wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com