Method for producing coated acidifier granules for feed

A production method and acidifying agent technology, applied in the molding or processing of animal feed, animal feed, animal feed, etc., can solve the problems of poor feed additive properties, volatile instability, corrosiveness, etc., and achieve good mixing and stability, enhanced acidification effect, low irritation and corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

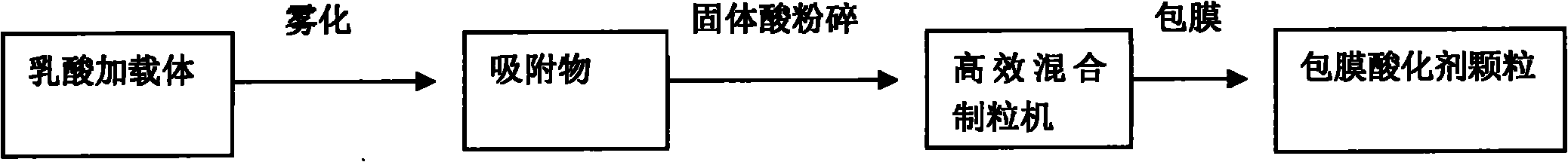

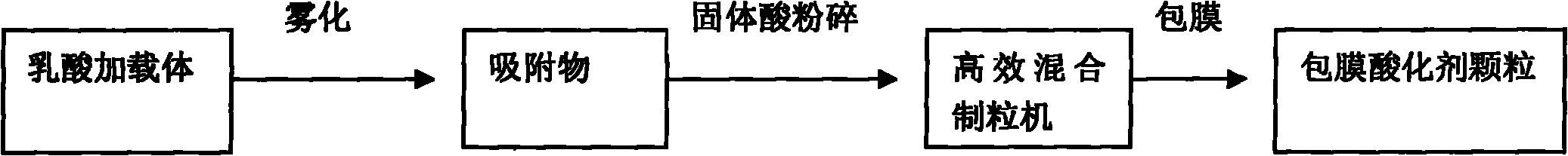

Method used

Image

Examples

Embodiment 1

[0023] Premixing of raw and auxiliary materials: 46kg of white carbon black is placed in a one-step granulator, and 25kg of lactic acid is sprayed into the granulator by a peristaltic pump for atomization and adsorption; Mesh sieve, after mixing with lactic acid adsorbate, add 7kg coating agent acrylic resin and triethyl citrate (mass ratio is 2:1) and carry out coating granulation in high-efficiency mixing granulator to obtain product. The granulation and coating process conditions are as follows: atomization pressure 0.2MPa, infusion volume 0.65kg / min, boiling temperature 50℃, air volume 3200m 3 / h.

Embodiment 2

[0025] Premixing of raw and auxiliary materials: 38kg of white carbon black is placed in a one-step granulator, and 30kg of lactic acid is sprayed into the granulator with a peristaltic pump for atomization and adsorption; Mesh sieve, after mixing with lactic acid adsorbate, add 8kg coating agent acrylic resin and triethyl citrate (mass ratio is 3.5:1) and carry out coating granulation in high-efficiency mixing granulator to obtain product. The granulation and coating process conditions are as follows: atomization pressure 0.3MPa, infusion volume 1.0kg / min, boiling temperature 65°C, air volume 4000m 3 / h.

Embodiment 3

[0027] Premixing of raw and auxiliary materials: 21kg of white carbon black is placed in a one-step granulator, and 35kg of lactic acid is sprayed into the granulator by a peristaltic pump for atomization and adsorption; Mesh sieve, after mixing with lactic acid adsorbate, add 15kg of coating agent acrylic resin and triethyl citrate (mass ratio is 5:1) and carry out coating granulation in a high-efficiency mixing granulator to obtain the product. The granulation and coating process conditions are as follows: atomization pressure 0.5MPa, infusion volume 1.2kg / min, boiling temperature 80°C, air volume 4800m 3 / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com