Method for producing cadmium nitrate and copper nitrate in preparation of cast iron ingots by arc process mixed iron slag

A technology of mixed iron and arc method, applied in copper nitrate, chemical instruments and methods, cadmium compounds, etc., can solve the problems of no treatment and utilization methods, environmental pollution, and harm to crop growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

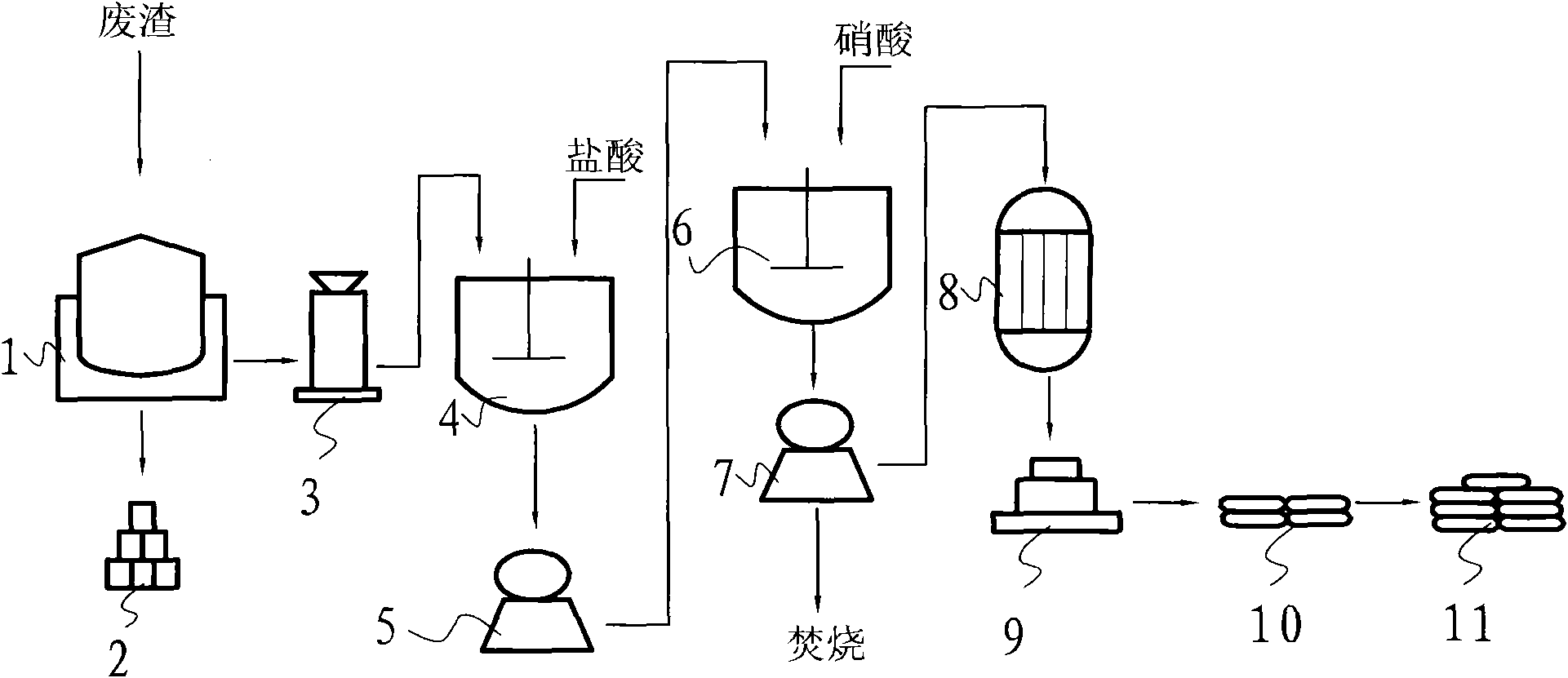

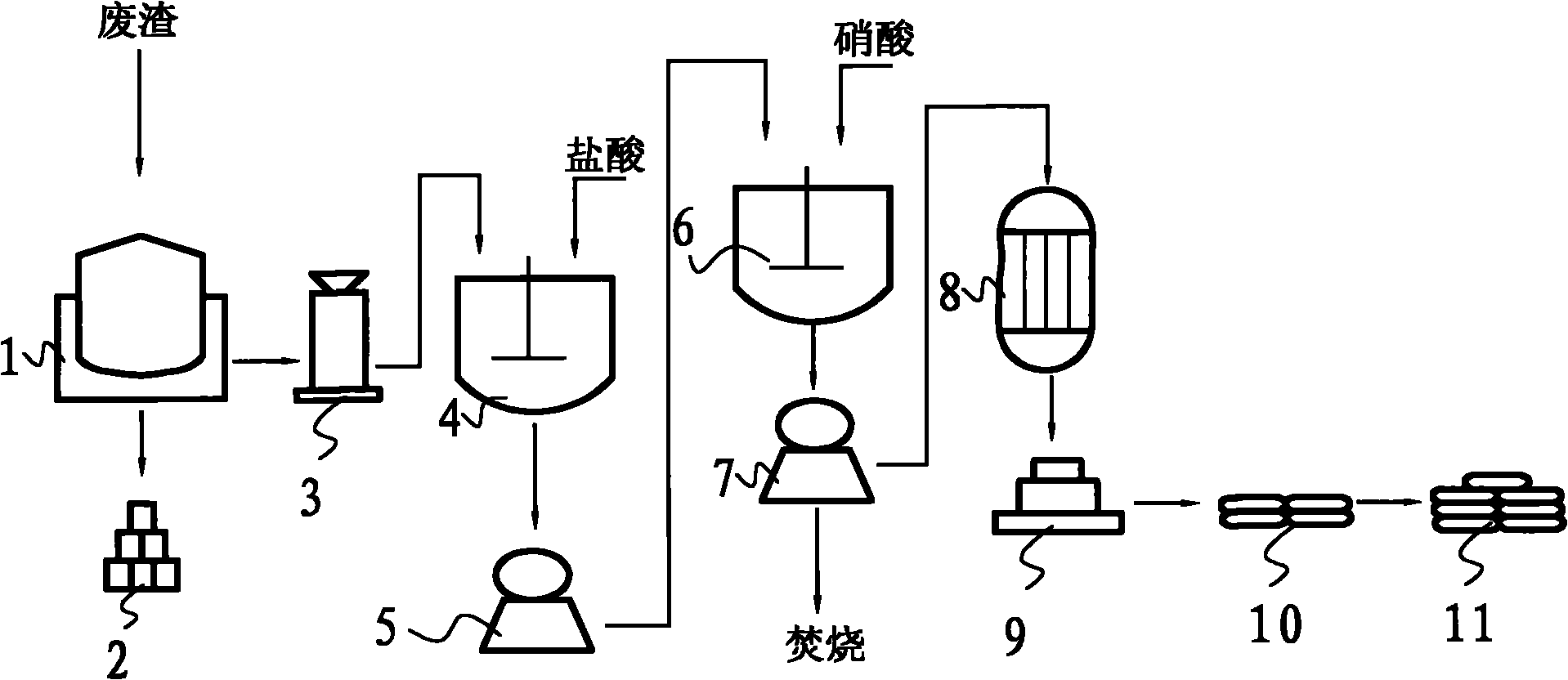

[0025] The method for producing iron ingots and co-producing cadmium nitrate and copper nitrate by electric arc method mixing iron slag comprises the following preparation steps:

[0026] Step A, put the iron slag mixed with electric arc method into the reverberatory furnace 1, and heat slowly (slowly heating at a rate of 2°C per minute) so that the temperature rises to 1600°C; at this time, the iron slag and its iron compounds have melted into The molten iron flows out, and the molten iron is used to produce iron ingots 2; part of the residual carbon monoxide and carbon dioxide gas is also volatilized with the temperature rise in the reverberatory furnace 1, and the remaining waste slag is discharged and cooled to the next process for further processing and extraction rare metal salts;

[0027] Step B, the remaining waste slag (in terms of 500kg pure copper oxide and 200kg pure cadmium oxide) in step A is first pulverized into 80 mesh coarse powder with pulverizer 3, and then...

Embodiment 2

[0033] The method for producing iron ingots and co-producing cadmium nitrate and copper nitrate by electric arc method mixing iron slag comprises the following preparation steps:

[0034] Step A, put the iron slag mixed with arc method into the reverberatory furnace 1, and heat slowly (slowly heating at a rate of 4°C per minute) to make the temperature rise to 1650°C; at this time, the iron slag and its iron compounds have melted into The molten iron flows out, and the molten iron is used to produce iron ingots 2; part of the residual carbon monoxide and carbon dioxide gas is also volatilized with the temperature rise in the reverberatory furnace 1, and the remaining waste slag is discharged and cooled to the next process for further processing and extraction rare metal salts;

[0035] Step B, the remaining waste slag (in terms of 500kg pure copper oxide and 200kg pure cadmium oxide) in step A is first pulverized into a 100-mesh coarse powder with a pulverizer 3, and then tran...

Embodiment 3

[0041] The method for producing iron ingots and co-producing cadmium nitrate and copper nitrate by electric arc method mixing iron slag comprises the following preparation steps:

[0042] Step A, put the iron slag mixed with the electric arc method into the reverberatory furnace 1, and slowly heat (slowly heat at a rate of 5°C per minute) so that the temperature rises to 1700°C; at this time, the iron slag and its iron compounds have melted into The molten iron flows out, and the molten iron is used to produce iron ingots 2; part of the residual carbon monoxide and carbon dioxide gas is also volatilized with the temperature rise in the reverberatory furnace 1, and the remaining waste slag is discharged and cooled to the next process for further processing and extraction rare metal salts;

[0043] Step B, the remaining waste slag (in terms of 500kg pure copper oxide and 200kg pure cadmium oxide) in step A is first pulverized into 120 mesh coarse powder with pulverizer 3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com