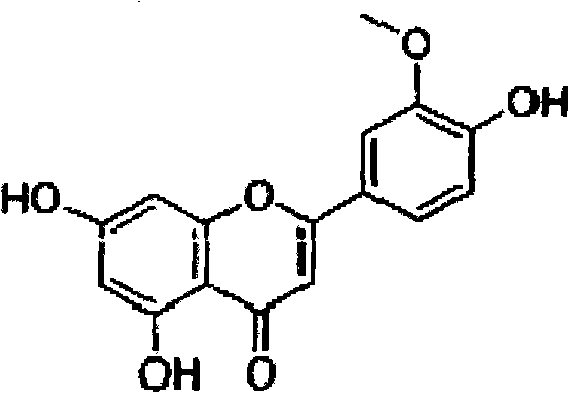

Preparation method of chrysoeriol

A technology of coirisin and medicinal materials, which is applied in the field of coirisin preparation, can solve the problems of low extraction rate and large loss of coirisin, and achieve the effects of short extraction time, easy control and prolonged service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take 10 kg of Artemisia wilt leaf powder, add 80 L of pH10 sodium hydroxide aqueous solution, and perform ultrasonic extraction at 45°C for 30 minutes, filter and then use 40 L of pH10 sodium hydroxide aqueous solution to ultrasonically extract once, and combine the two filtrates. The pH of the filtrate was adjusted to neutrality with hydrochloric acid, centrifuged at 3000 r / min for 15 minutes, the precipitate was added with an appropriate amount of distilled water to make a 1L suspension, and 1L of chloroform was added to the suspension for continuous ultrasonic extraction, and the extraction was performed twice. The lower layer was removed, and the upper layer was continuously ultrasonically extracted twice with 1L of ethyl acetate. The four extractions were combined for a total of 4L, and were then subjected to microfiltration, ultrafiltration and nanofiltration in a multifunctional membrane separation device. The filter membrane material is a polyvinylidene fluoride ...

Embodiment 2

[0030] Take 10 kg of peony seed powder, add 100 L of sodium hydroxide aqueous solution with pH 9, ultrasonically extract at 50 ° C for 1 hour, filter and then use 50 L of sodium hydroxide aqueous solution with pH 9 to ultrasonically extract once, and combine the two filtrates. The filtrate was adjusted to neutral pH with hydrochloric acid, centrifuged at 3000r / min for 10 minutes, the precipitate was added with an appropriate amount of distilled water to make a 1L suspension, and 1L of chloroform was added to the suspension for continuous ultrasonic extraction, and the extraction was performed twice. The lower layer was removed, and the upper layer was continuously ultrasonically extracted twice with 1L of ethyl acetate. The four extractions were combined for a total of 4L, and microfiltration, ultrafiltration and nanofiltration were carried out in sequence in a multifunctional membrane separation device. The operating pressure was 1.5bar, wherein The microfiltration membrane is...

Embodiment 3

[0032] Take 50 kg of chrysanthemum brain whole herb powder, add 600 L of pH10 sodium hydroxide aqueous solution for 1.5 hours at 60°C for ultrasonic extraction, filter and then ultrasonically extract once with 300 L of pH10 sodium hydroxide aqueous solution, and combine the two filtrates. The filtrate was adjusted to neutral pH with hydrochloric acid, centrifuged at 3000r / min for 10 minutes, the precipitate was added with an appropriate amount of distilled water to make a 5L suspension, and 5L of chloroform was added to the suspension for continuous ultrasonic extraction, and the extraction was performed twice. The lower layer was removed, and the upper layer was continuously ultrasonically extracted twice with 5L of ethyl acetate. The four extractions were combined for a total of 20L, and microfiltration, ultrafiltration and nanofiltration were carried out successively in a multifunctional membrane separation device. The operating pressure was 1.5bar, wherein The microfiltrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com