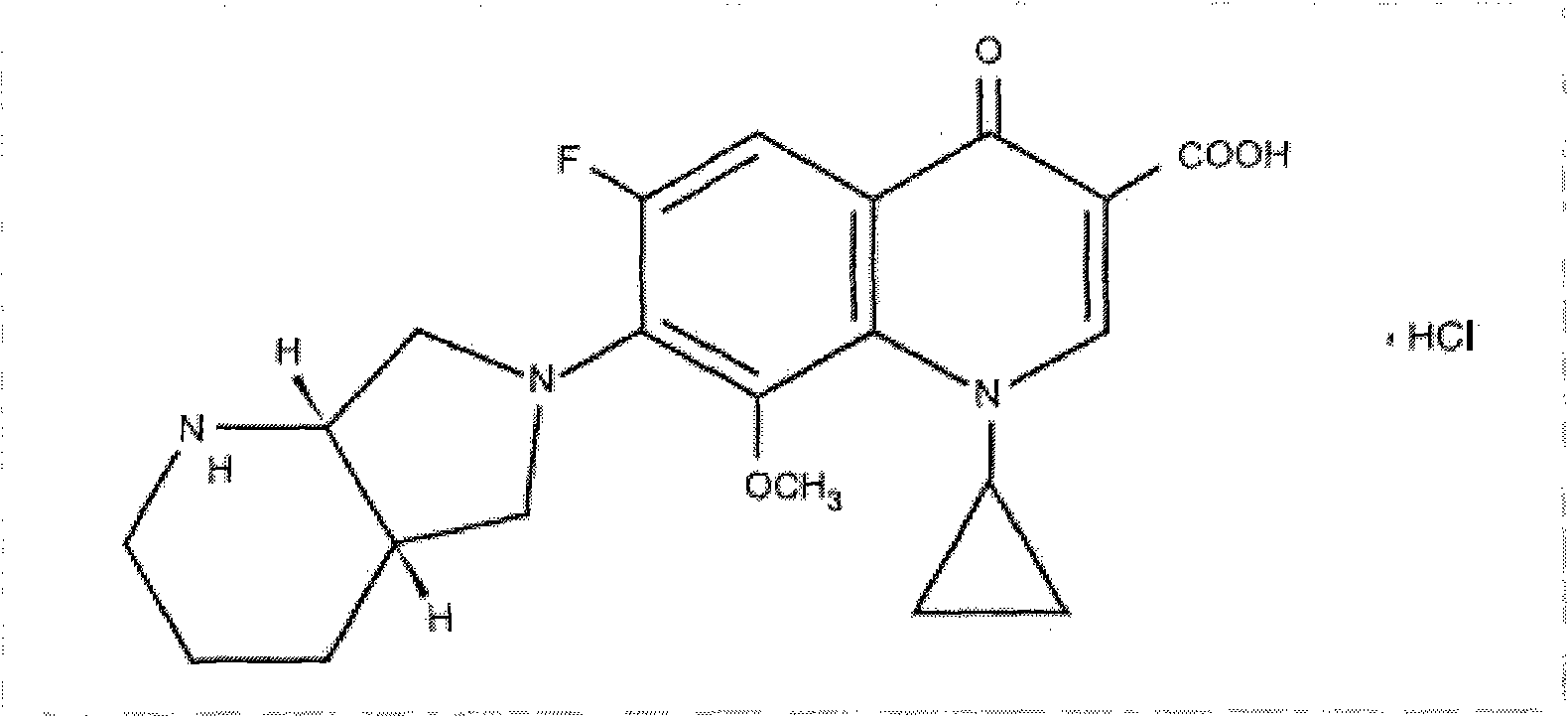

Synthesizing method of moxifloxacin hydrochloride

A technology of moxifloxacin hydrochloride and a synthesis method, applied in the field of medicinal chemistry, can solve the problems of difficulty in realizing industrialized production, cumbersome post-processing operations, product loss, etc., and achieve the effects of reducing operation steps, process optimization, and improving selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] For a better description of the present invention, examples are as follows:

[0017] 1. Synthesis of quinoline carboxylic acid borane chelate

[0018] Take 86g of acetic anhydride and add it to a three-necked flask, add 3g of zinc chloride as a catalyst, stir at room temperature and slowly add 17.3g of boric acid to keep the temperature stable. After the addition, raise the temperature to 100°C for 3 hours. After the reaction was completed, the temperature was lowered to 70°C, and 83g (1-cyclopropyl-6,7-difluoro-1,4-dihydro-8-methoxy-4-oxo-3-quinolinecarboxylic acid) was added and stirred After 10 minutes, the temperature was raised to 100°C and the reaction was stirred for 3 hours. After the reaction was completed, the temperature was lowered to 40° C., then poured into 600 ml of frozen purified water and vigorously stirred. A large amount of solids precipitated, filtered, washed twice with ice water, dried and weighed: 89.5g.

[0019] 2. Synthesis of borane chelate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com