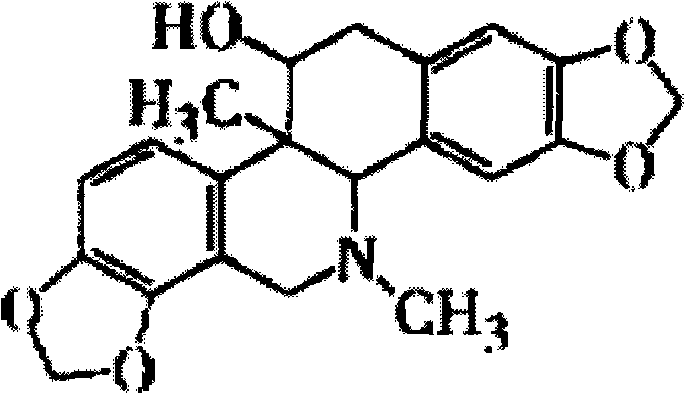

Method for extracting corynoline

An extraction method and a technology for Corydalin, which are applied in the field of extraction of Corydalin, can solve problems such as few methods for extracting Corydalin, and achieve the effects of high product yield, reduced dosage, and improved processing capacity and effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take kudiding medicinal material and grind it into 80 meshes, take 1kg and add 5 times the amount of 90% methanol for ultrasonic extraction for 1 hour, extract 3 times, filter the extract, recover methanol under reduced pressure with a rotary evaporator, add 100g of alumina to a small volume and mix well Dry (medium alumina is neutral alumina, particle size 120-200 mesh), crush and add 500ml acetone for ultrasonic extraction 3 times, extract acetone with rotary evaporator and dry. Take chloroform, methanol, and water to prepare a high-speed countercurrent chromatography solvent system in a ratio of 25:35:17. After shaking and shaking in a separatory funnel, the upper phase is used as the mobile phase to dissolve the dry matter, and the lower phase is used as the stationary phase. The flow rate was 2ml / min, the reverse rotation speed was 700r / min, the above crude extract was separated by high-speed countercurrent chromatography, the fraction of Corydalis was collected, th...

Embodiment 2

[0025] Take kudiding medicinal material and crush it into 40 meshes, take 1 kg and add 8 times the amount of 80% methanol for ultrasonic extraction for 1 hour, extract twice, filter the extract, recover methanol under reduced pressure with a rotary evaporator, add 150 g of alumina to a small volume and mix well Dry (medium alumina is neutral alumina, particle size 120-200 mesh), crush and add 800ml of 80% acetone for ultrasonic extraction twice, extract acetone with a rotary evaporator and dry. Take chloroform, methanol, and water to prepare a high-speed countercurrent chromatography solvent system in a ratio of 27:37:20. After shaking and layering in a separating funnel, take the upper phase as the mobile phase to dissolve the dry matter, and take the lower phase as the stationary phase. The flow rate was 3ml / min, the reverse rotation speed was 800r / min, the above crude extract was separated by high-speed countercurrent chromatography, the fraction of Corydalis was collected, ...

Embodiment 3

[0027] Take Kudiding medicinal material and crush it into 60 meshes, take 2kg and add 5 times the amount of 90% methanol for ultrasonic extraction for 1 hour, extract 3 times, filter the extract, recover methanol under reduced pressure with a rotary evaporator, add 200g of alumina and mix evenly to a small volume Dry (medium alumina is neutral alumina, particle size 120-200 mesh), pulverize, add 1000ml acetone and ultrasonically extract 3 times, use rotary evaporator to recover acetone from the extract until dry. Take chloroform, methanol, and water to prepare a high-speed countercurrent chromatography solvent system in a ratio of 25:30:17. After shaking and layering in a separating funnel, take the upper phase as the mobile phase to dissolve the dry matter, and take the lower phase as the stationary phase. The flow rate was 2ml / min, the reverse rotation speed was 700r / min, the above crude extract was separated by high-speed countercurrent chromatography, the fraction of Coryda...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com