Modified acrylic resin-based normal temperature quick-drying automobile paint with high fullness and high solid

A technology of acrylic resin and acrylic ester, which is applied in the direction of coating, etc., can solve the problems of poor weather resistance, inability to use, easy yellowing of vinyl toluene, etc., and achieve good fullness, high solid content, and high fullness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

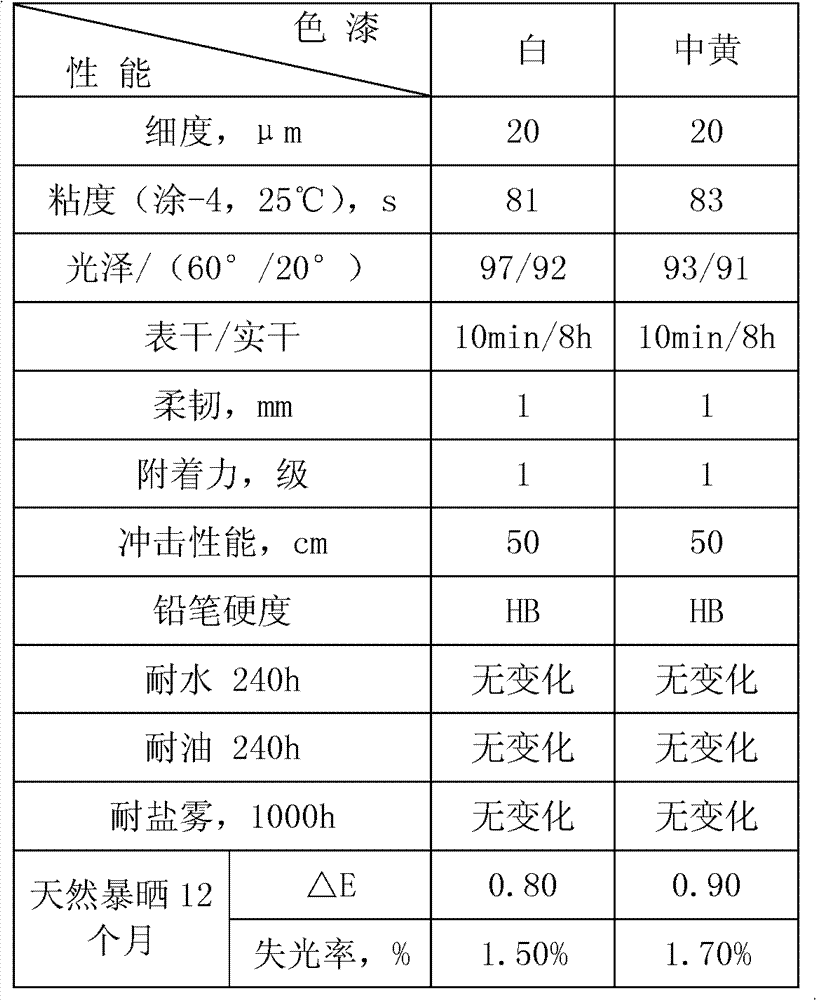

Examples

Embodiment 1

[0022] Example 1: Put 6% soyoleic acid, 2% tall oil acid, 5% phthalic anhydride, and 5% pentaerythritol into a stainless steel reactor, start stirring, heat up to 160°C, keep warm for 1 hour, then heat up to 200°C for 4 Hours later, take a sample to measure the acid value. When the acid value reaches 8-12mgKOH / g, cool down to 120°C, add xylene, stir evenly, and start adding dropwise at 120±5°C, 40% butyl methacrylate, 20% Hydroxypropyl acrylate, 1% methacrylic acid, 20% styrene, 1% benzoyl peroxide, take a sample to measure the viscosity after 4 hours, and wait for the viscosity to pass 50-200 seconds (50% solid content in xylene, apply -4 cups / 25°C), filter pack. See Table 1 for specific parameters.

Embodiment 2

[0023] Embodiment 2: drop into 5% linolenic acid, 1% soybean oil acid, 2% ricinoleic acid, 5% phthalic anhydride, 6% trimethylol propane in the stainless steel reactor, operation technique and control index are the same as embodiment 1, reach After the requirement, start to drop 40% butyl acrylate, 19% hydroxypropyl acrylate, 1% methacrylic acid, 20% styrene, 1% benzoyl peroxide, and the operation process and control index are the same as in Example 1. See Table 1 for specific parameters.

Embodiment 3

[0024] Embodiment 3: drop into 7% tall oil acid, 3% dehydrated ricinoleic acid, 5% isophthalic acid, 5% pentaerythritol in the stainless steel reactor, operation technique and control index are the same as embodiment 1, after meeting the requirements, start Add dropwise 40% butyl methacrylate, 20% hydroxypropyl acrylate, 1% methacrylic acid, 18% styrene, and 1% benzoyl peroxide. The operating process and control indicators are the same as in Example 1. See Table 1 for specific parameters.

[0025] Table 1 Modified acrylic resin index of the present invention

[0026] serial number

project

Example 1

Example 2

Example 3

1

clarity and transparency

clear, transparent

clear, transparent

clear, transparent

2

Color (Fe-Co method), No.

5

9

5

3

Viscosity (Tu-4 / 25℃), s

70

98

76

4

Acid value, mgKOH / g

10.7

11.1

10.5

5

Non-volatile mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com