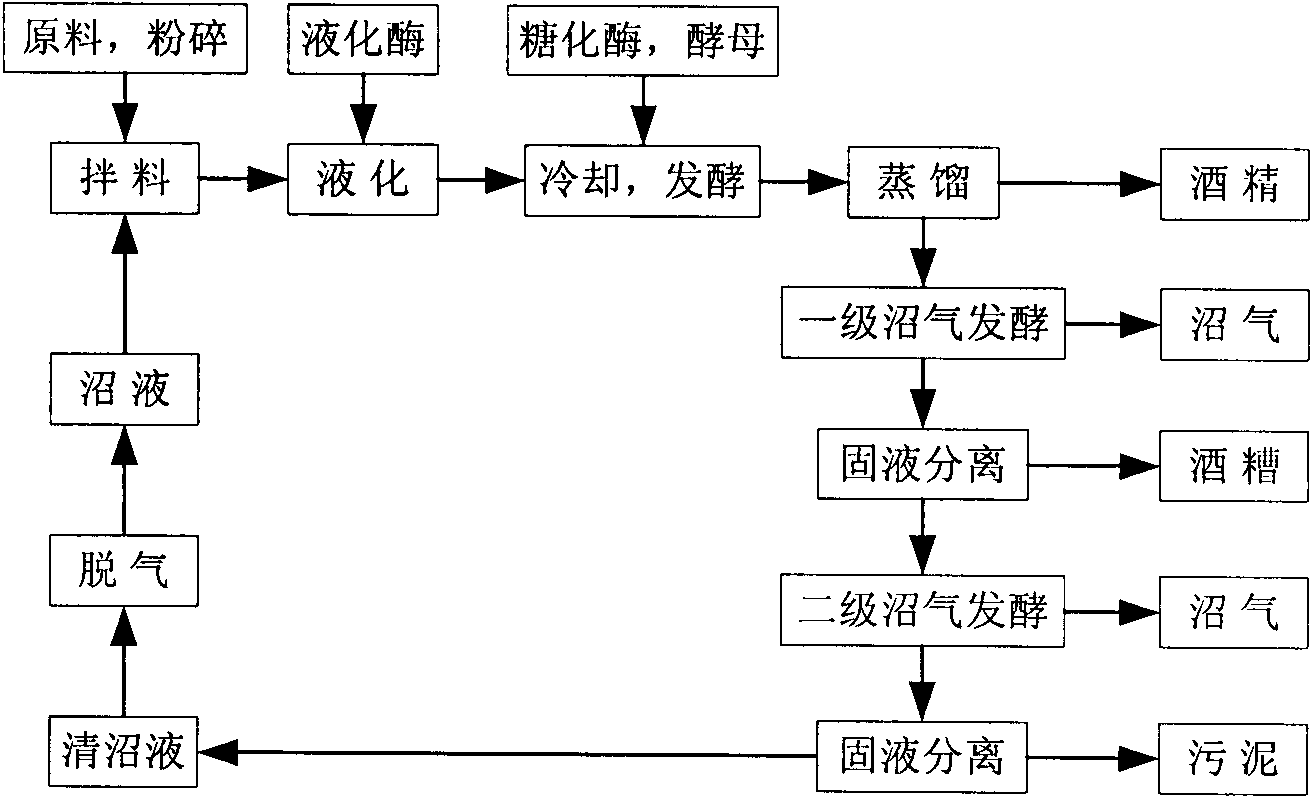

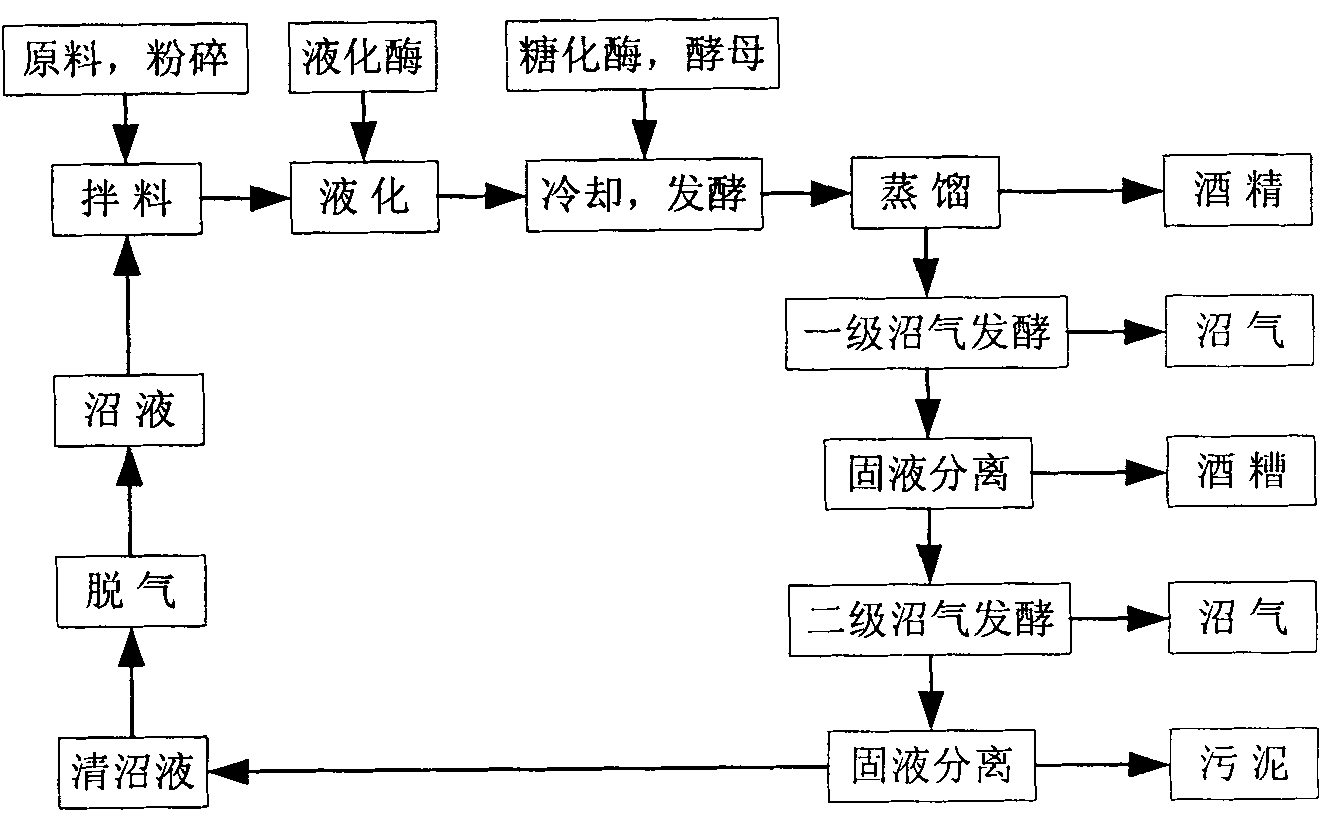

Method for ecologically producing alcohol by taking tuberous crop as raw material

A manufacturing method and a technology for raw materials, applied in the field of alcohol ecological manufacturing, can solve problems such as alcohol pollution, and achieve the effects of eliminating the problem of large land occupation, saving water resources, and eliminating high-concentration wastewater pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment one: a kind of alcohol ecological production method using potatoes as raw material adopts the following process steps:

[0038] The raw material is dried cassava. The dried cassava is crushed and passed through a 30-mesh sieve. According to the ratio of feed water mass ratio of 1:3, the previous batch of degassed biogas slurry was added. During the mixing process, the pH of cassava starch slurry was adjusted to 6.2 with sulfuric acid, and then commercial high-temperature-resistant α-amylase was added. The amount of amylase added is 10u / g starch. After the mixing, the starch slurry was cooked at 105°C for 45 minutes to fully liquefy the starch. After cooking and liquefaction, the liquefied liquid is rapidly cooled down to 30°C, and then commercial glucoamylase is added. The amount of glucoamylase added is 100u / starch. Insert the cultured yeast seed liquid to start fermentation, and the inoculum amount of the yeast seed liquid is 10% of the volume of the li...

Embodiment 2

[0041] Embodiment two: a kind of alcohol ecological production method using potatoes as raw material adopts the following process steps:

[0042] Using fresh cassava as raw material, spray and wash the fresh cassava with water to remove the sediment on the surface of the cassava, then crush it, and pass it through a 20-mesh sieve. The degassed biogas slurry was added according to the ratio of material to water mass ratio of 1:1.5. During the mixing process, sulfuric acid was used to adjust the pH of cassava starch slurry to 6.6, and commercial high-temperature-resistant α-amylase was added. The amount of amylase added is 12u / g starch. The starch slurry after mixing was steamed at 105°C for 60 minutes to fully liquefy the starch. After cooking and liquefaction, cool the liquefied liquid to 28°C, and then add commercial glucoamylase in an amount of 150u / starch. Insert the cultured yeast seed liquid to start fermentation, and the inoculum amount of the yeast seed liquid is 12% ...

Embodiment 3

[0045] Embodiment three: a kind of alcohol ecological production method using potatoes as raw material adopts the following process steps:

[0046] Using dried sweet potato as raw material, crush the dried sweet potato and pass through a 40-mesh sieve. Add the degassed biogas slurry mixing material according to the ratio of feed water mass ratio of 1:3, adjust the pH of cassava starch slurry to 5.6 with sulfuric acid in the mixing process, add commercial high temperature resistant α-amylase, the amount of amylase added is 8u / g starch, cook at 105°C for 120 minutes to fully liquefy the starch; after cooking and liquefaction, cool the liquefied liquid to 28°C, then add commercial glucoamylase, the amount of glucoamylase added is 80u / starch; The cultured yeast seed liquid starts to ferment, and the inoculum amount of the yeast seed liquid is 8% of the volume of the liquefied liquid. After the alcoholic fermentation is finished, the fermented liquid is distilled to obtain the fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com