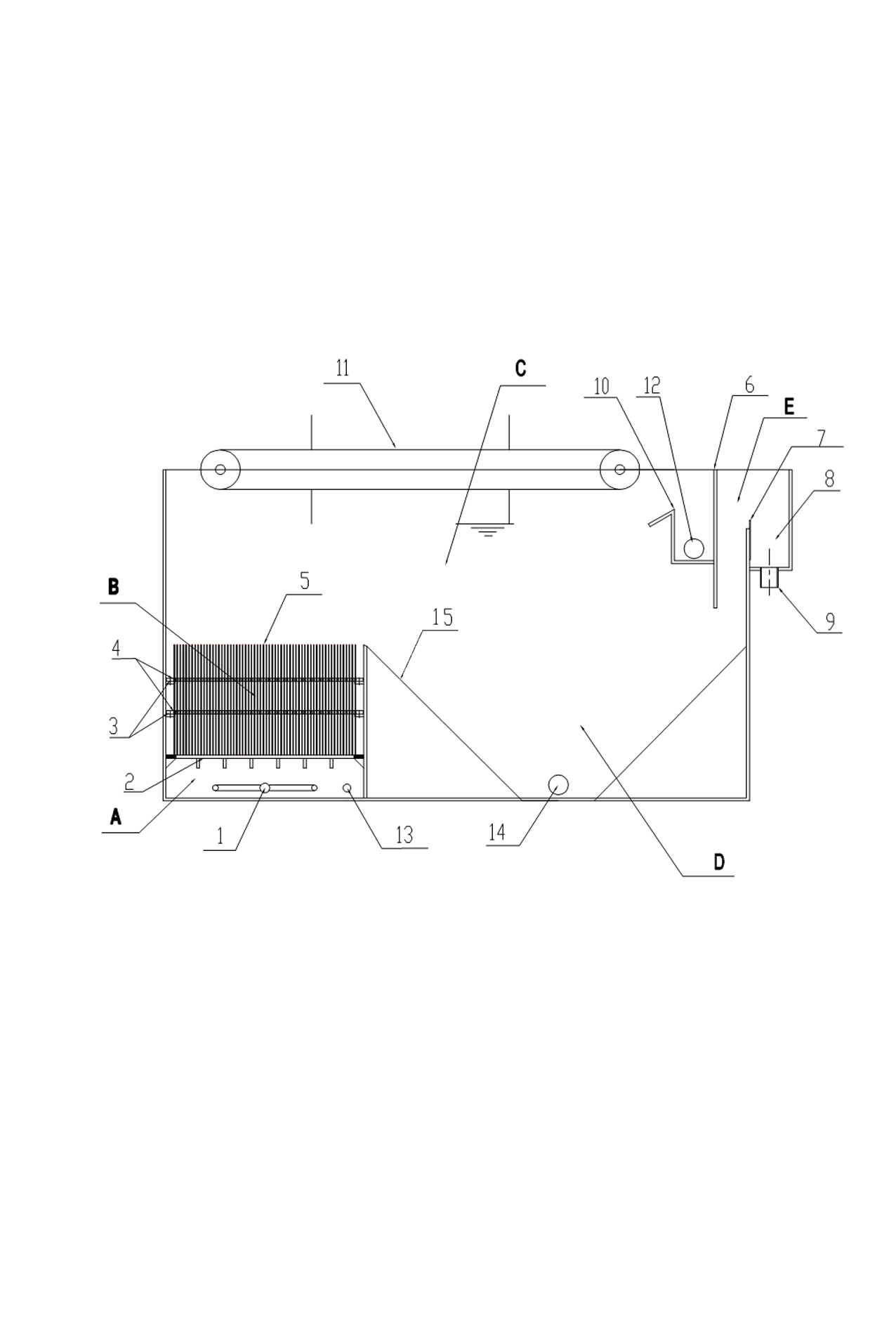

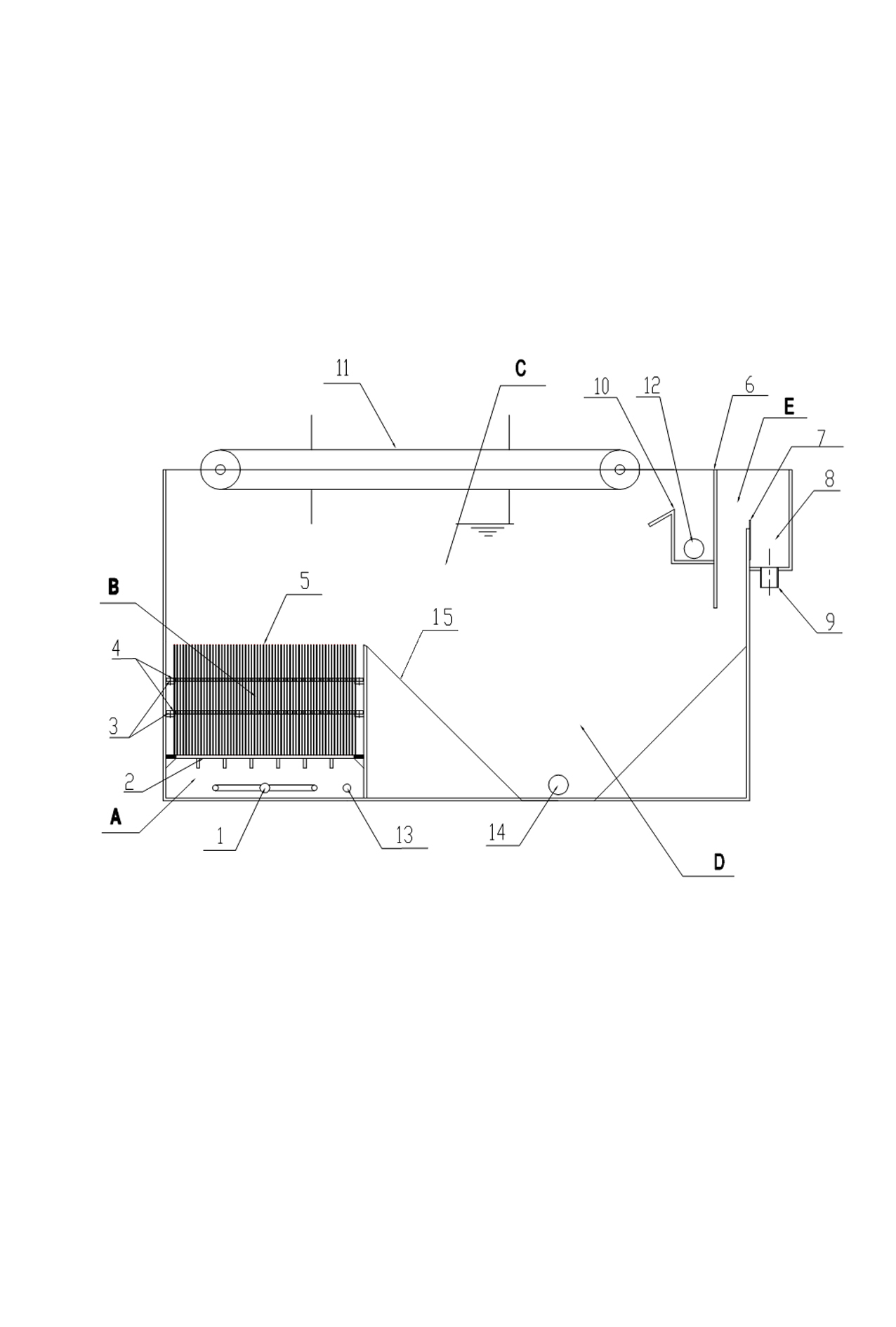

Electric flocculation-air flotation integrated waste water treatment equipment

A technology of wastewater treatment and electro-flocculation, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Problems such as difficulty in replacement, to achieve the effect of saving fixed investment and floor space, reducing cell voltage and energy consumption, and preventing electrode passivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] Example: In June 2008, a set of printing and dyeing wastewater treatment facilities with electrocoagulation-air flotation integrated equipment as the core was established in the printing and dyeing workshop of a certain garment factory in Shenyang for experiments. The experiments proved that the treatment capacity is 5m 3 / h. The wastewater treatment facility has a simple process, compact equipment structure, easy to realize automatic control, continuous and stable operation so far, and no safety and technical problems have occurred. The effluent quality of the wastewater treatment facility is stable, and all indicators have reached the national secondary standard for comprehensive sewage discharge. The processing equipment covers an area of less than 10m 2 , with a total investment of 140,000 yuan. The operating cost per ton of water is 1.2 to 1.5 yuan, which can be accepted by enterprises. Compared with other treatment processes of the same type of wastewater, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com