Chitosan bandage

A chitosan-integrated technology, applied in the field of medical equipment, can solve the problems of easy shedding of dressings, poor elasticity, lack of waterproof function, etc., and achieve the effects of not easy pollution and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

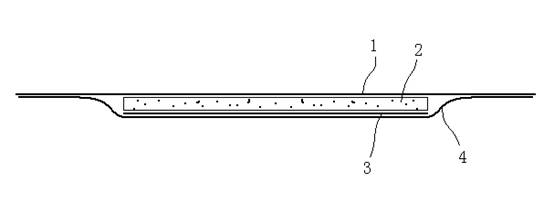

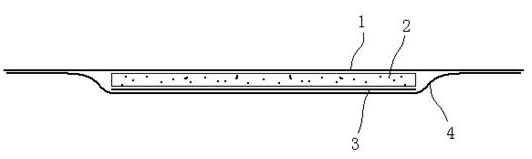

[0013] See the accompanying drawings, the chitosan protective bandage includes a composite base material layer 1, a biofilm layer and a protective layer 4; the biofilm layer uses medical polyurethane resin glue as an intermediate medium to make chitosan fibers The cloth 3 is composited with the medical absorbent pad 2, the substrate layer 1 is made of TPU medical film with medical polyurethane resin glue combined with the medical absorbent pad 2 of the biofilm layer, and the protective layer 4 is ordinary release paper covered on the biofilm layer Chitosan fibers on nonwoven fabric 3.

[0014] Instructions

[0015] 1. Repeatedly clean the wound surface and pasted parts with normal saline or disinfectant water;

[0016] 2. Use sterile gauze to dry the wound and pasted parts, and keep the wound and pasted parts dry and clean before pasting;

[0017] 3. Take this product with appropriate specifications, remove the protective layer, and make the middle biofilm layer completely c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com