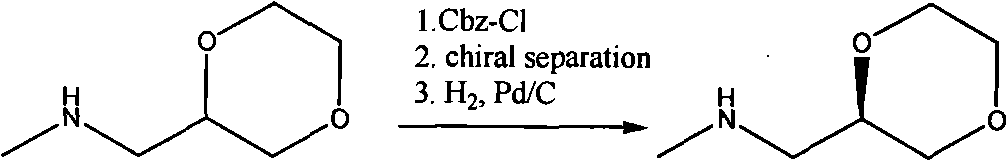

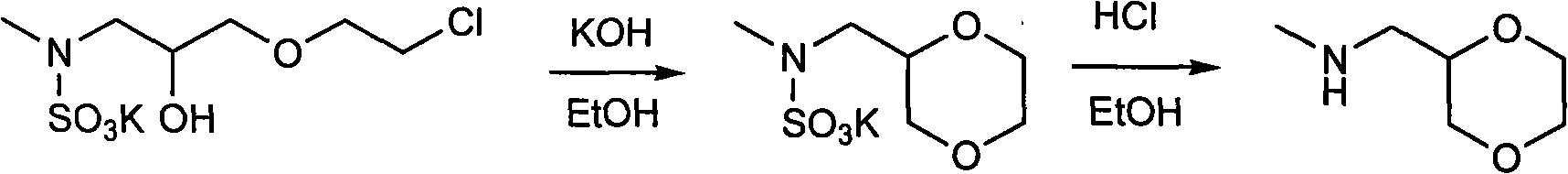

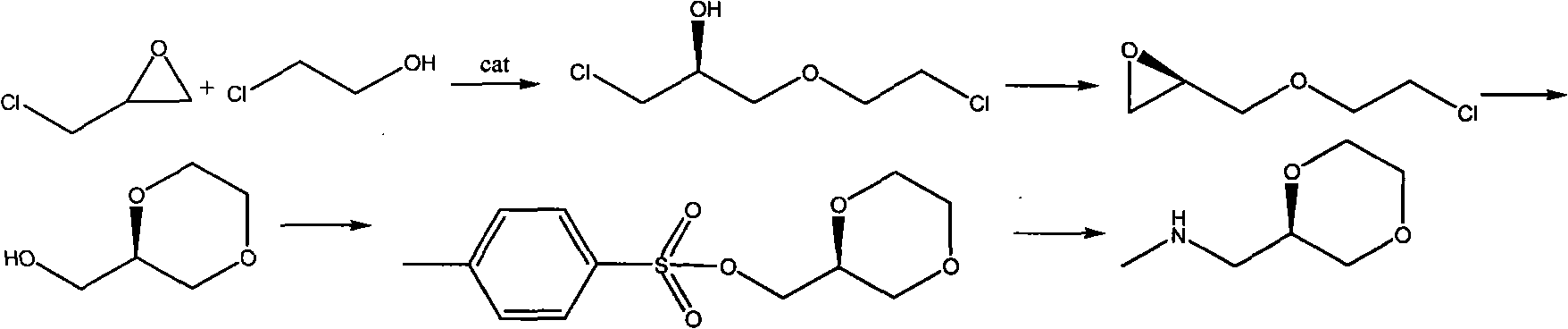

Synthesis process of (2R)-(1,4-dioxane-2-yl)-N-methyl-methanamine hydrochloride

A technology of methyl methylamine hydrochloride and synthesis process, applied in directions such as organic chemistry, can solve problems such as high cost of chiral column, bringing in by-products, difficulty in industrialization, etc., avoiding chiral splitting, simple raw materials, The effect of easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Add 0.05 grams of [(R, R)-N, N'-bis(3,5-di-tert-butyl salicylidene)-1,2-cyclohexanediamine cobalt in a four-necked flask 2 ·SnCl 2 100 grams of epichlorohydrin and 50 grams of 2-chloroethanol were reacted at 0°C for 12 hours, cooled to 10°C, added 500 grams of dichloromethane, neutralized to pH= 7.0-8.0, standing to separate layers, drying the organic layer with anhydrous sodium sulfate, distilling off dichloromethane to obtain crude product 81.3 of (S)-3-(2-chloroethoxy)-1-chloropropan-2-ol gram, gas chromatography analysis, content 93.7%, directly used in next step reaction;

[0020] 2) Add 250 grams of acetone in a four-necked flask, 50 grams of (S)-3-(2-chloroethoxy)-1-chloropropan-2-alcohol and 50 grams of sodium carbonate reflux reaction for 3 hours, cooled to 0 ℃, filter, remove insoluble matter, distill off acetone, obtain (2R)-2-[(2-chloroethoxy) methyl] oxirane crude product 28.9 grams, gas chromatography analysis, content 91.6%, directly for the next re...

Embodiment 2

[0024] 1) Add 0.05 grams of [(R, R)-N, N'-bis(3,5-di-tert-butyl salicylidene)-1,2-cyclohexanediamine cobalt in a four-necked flask 2 ·SnCl 4 100 grams of epichlorohydrin and 100 grams of 2-chloroethanol were reacted at 20°C for 24 hours, cooled to 20°C, added 500 grams of dichloromethane, neutralized to pH= 7.0-8.0, standing to separate layers, the organic layer was dried with anhydrous sodium sulfate, dichloromethane was evaporated to obtain (S)-3-(2-chloroethoxy)-1-chloropropan-2-ol crude product 70.5 gram, gas chromatography analysis, content 93.5%, directly used in next step reaction;

[0025] 2) Add 250 grams of acetone in a four-necked flask, 50 grams of (S)-3-(2-chloroethoxy)-1-chloropropane-2-alcohol and 150 grams of sodium carbonate reflux reaction for 5 hours, cooled to 10 DEG C, filter, remove insoluble matter, evaporate acetone, obtain (2R)-2-[(2-chloroethoxy) methyl] oxirane crude product 28.1 grams, gas chromatography analysis, content 91.6%, directly for the ...

Embodiment 3

[0029] 1) Add 0.05 grams of [(R, R)-N, N'-bis(3,5-di-tert-butyl salicylidene)-1,2-cyclohexanediamine cobalt in a four-necked flask 2 ·FeCl 3 100 grams of epichlorohydrin and 75 grams of 2-chloroethanol were reacted at 15°C for 20 hours, cooled to 15°C, added 500 grams of dichloromethane, neutralized to pH= 7.0-8.0, standing to separate layers, drying the organic layer with anhydrous sodium sulfate, evaporating dichloromethane to obtain (S)-3-(2-chloroethoxy)-1-chloropropan-2-ol crude product 80.0 gram, gas chromatography analysis, content 93.7%, directly used in next step reaction;

[0030] 2) Add 250 grams of acetone in a four-necked flask, 50 grams of (S)-3-(2-chloroethoxy)-1-chloropropan-2-alcohol and 75 grams of potassium carbonate reflux reaction for 4 hours, cooled to 0 ℃, filter, remove insoluble matter, evaporate acetone, obtain (2R)-2-[(2-chloroethoxy) methyl] oxirane crude product 29.1 grams, gas chromatography analysis, content 91.5%, directly for the next reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com