Method and system for recovering light hydrocarbon by oil field associated gas membrane method

A technology for the recovery of associated gas and light hydrocarbons in oilfields, applied in the field of its recovery system, can solve the problems of affecting transportation, easy clogging of combustion nozzles, waste of resources, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

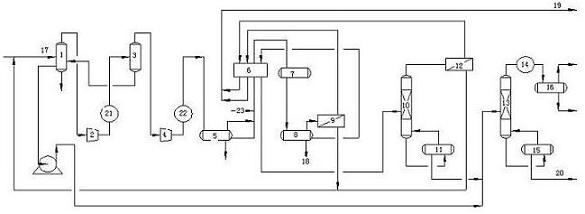

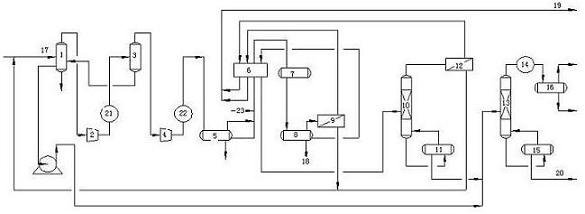

[0023] Such as figure 1 In the oilfield associated gas film method light hydrocarbon recovery system shown, the inlet of raw gas buffer tank 1 is connected to oilfield associated gas inlet 17, the liquid outlet at the bottom of the raw gas buffer tank is connected to the liquefied gas tower 13 through pipelines, and the gas outlet at the top of the raw gas buffer tank is The pipeline installed with the primary compressor 2 and the water cooler 21 is connected to the inlet of the primary liquid separation tank 3, and the gas outlet at the top of the primary liquid separation tank is connected to the secondary gas outlet through the pipeline equipped with the secondary compressor 4 and the air cooler 22. The liquid tank 5, the sewage outlet at the bottom of the secondary separation tank 5 is connected to the sewage treatment system, the gas phase outlet and the liquid phase outlet at the top are connected to the liquid inlet pipeline, and the multi-flow cold box 6 is the liquid i...

Embodiment 2

[0025] The oilfield associated gas membrane light hydrocarbon recovery system described in Example 1 is used to recover light hydrocarbons from oilfield associated generators. The specific process is as follows:

[0026] The first step of shallow cold compression: the slightly positive pressure oilfield associated gas enters the raw material gas buffer tank after metering (see attached picture), and enters the first-stage compressor after liquid separation, boosting the pressure to about 0.6MPa, and the temperature reaches about 120°C. After the cooling water is condensed to about 40°C, it enters the first-stage liquid separation tank for liquid separation, and then enters the second-stage compressor to increase the pressure to about 2.2MPa, and the temperature reaches about 120°C. After cooling to about 40°C by air cooling, it enters the second-stage liquid separation tank. tank, sewage to the sewage treatment system, the gas phase and liquid phase are mixed and injected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com