Novel esterase and application thereof

A new type of esterase technology, applied in the field of genetic engineering, to achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

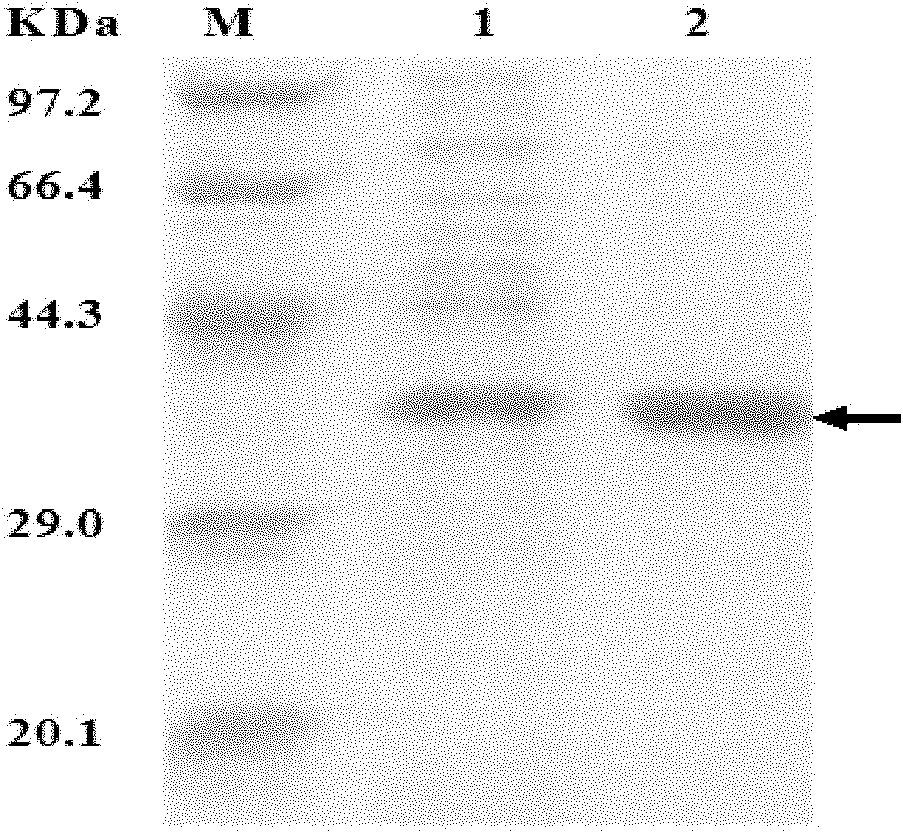

[0035] Example 1 Establishment of metagenomic library and acquisition of positive clones, gene cloning and expression

[0036] 1. Extraction of total DNA:

[0037] Weigh 6g sample, add 13.5mL DNA extraction buffer (0.1M Tris, 0.1M EDTA-Na, 0.1M Na 3 PO 4 , 1.5M NaCl, 1% CTAB, pH 8.0), shake vigorously for 3-5min, add 200μL lysozyme (100mg / ml), invert repeatedly 5-6 times, 37℃ water bath for 30min, add 1.5ml 20% SDS, 65 ℃ water bath for 1 h (during this period, turn it upside down several times every 15 min), centrifuge at 8000 r / min for 5 min, take the supernatant, extract twice with an equal volume of chloroform, centrifuge at 16000 r / min for 10 min, take the supernatant, add 0.6 times the volume of iso Propanol, place at room temperature for 2 hours, centrifuge at 20,000r / min for 20min, discard the supernatant, add 5mL of pre-cooled 70% ethanol to the pellet, centrifuge at 20,000r / min for 10min, collect the DNA precipitate, air-dry, and dissolve with an appropriate amount ...

Embodiment 2

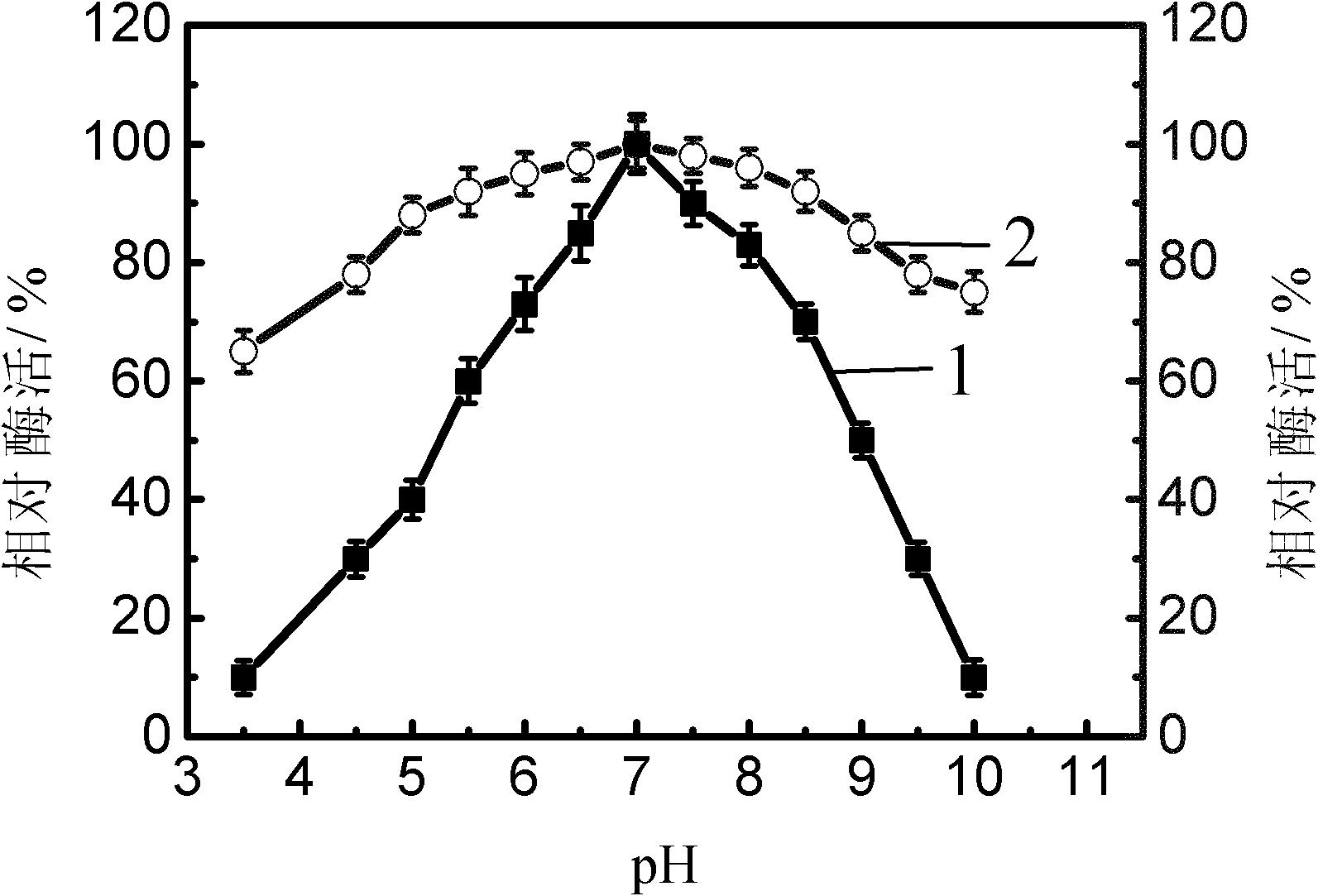

[0060] Research on the enzymatic properties of embodiment 2 recombinant esterase F816

[0061] Weigh 11 mg of p-nitrophenol acetate, dissolve it completely with 1 mL of methanol, then pipette 0.4 mL of p-nitrophenol acetate solution into 9.6 mL of 0.05M Tris-HCl (pH=6.8) buffer solution, and take 100 μL of the enzyme solution to be tested was added to 2 mL of p-nitrophenol acetate solution, and incubated for 5 minutes. At the same time, the inactivated crude enzyme solution was used as a control, and the light absorption value was measured at 405 nm. The greater the absorption value, the higher the enzyme activity.

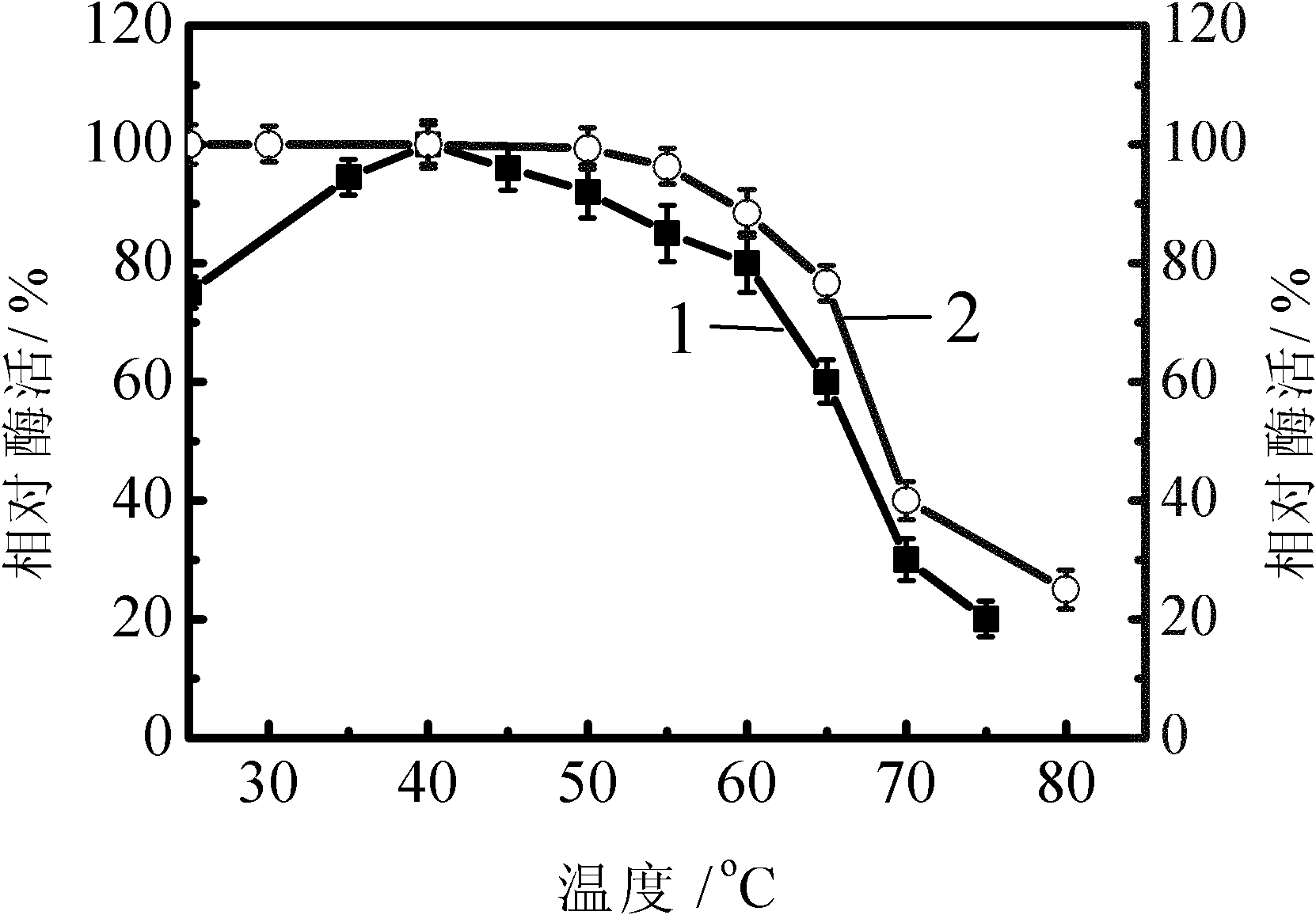

[0062] 1. Optimum reaction temperature and thermal stability of recombinant esterase F816

[0063] After the crude enzyme solution of recombinant esterase F816 is subjected to enzymatic reaction at 20-80° C., its enzyme activity is measured according to the above method to obtain its optimum reaction temperature (recorded as 100% when the enzyme activity is the hi...

Embodiment 3

[0070] Degradability determination of embodiment 3 recombinant esterase F816 pyrethroid pesticides

[0071] In this study, cyhalothrin, cypermethrin, fenvalerate and deltamethrin were selected as the degradation objects, and GC-2010 gas chromatography (Shimadzu Corporation, Japan) was used for quantitative analysis to determine the effect of recombinant esterase F816 on pyrethroids. Degradability of pesticides.

[0072] 1. Sample processing

[0073] Add 0.3mL of crude enzyme solution to 1mL of cyhalothrin, cypermethrin, fenvalerate and deltamethrin with a concentration of 4mg / L, and add 0.3mL of crude enzyme solution to 1mL of pH 6.8 0.1 M potassium phosphate buffer, add 0.1M potassium phosphate buffer with pH 6.8 to a final volume of 4 mL, react at 37°C for 60 min, add n-hexane to the sample to be tested at a ratio of 1:2 (v / v), Shake on a constant temperature shaker for 20min (200r / min), absorb the supernatant and dilute to 1mL, accurately absorb 1μL and perform quantitati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com