Method for preparing core-reinforced multi-core MgB2 superconducting wires/strips

A superconducting wire and core technology, which is applied in the field of core-reinforced multi-core MgB2 superconducting wire/strip preparation, can solve the problems of core wire sausage shape, wire breakage, multi-core superconducting wire strip breakage, etc., and achieves increased strength , to avoid the effect of uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

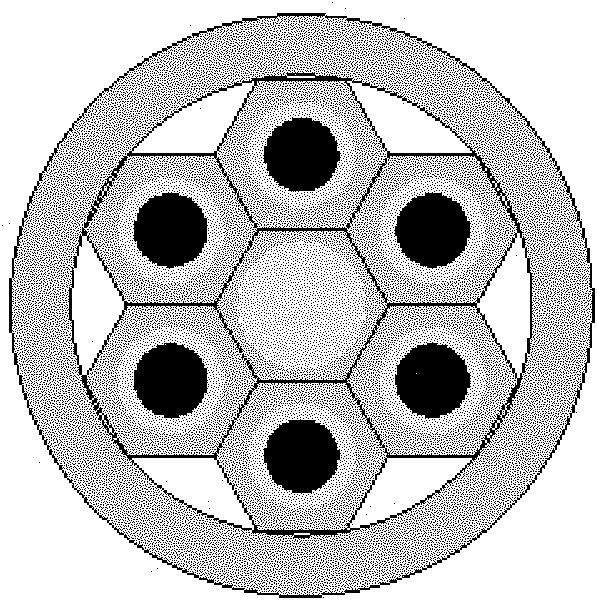

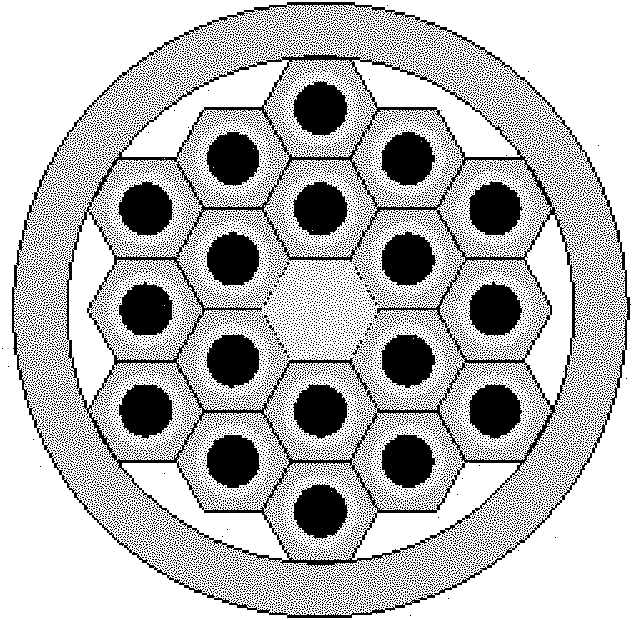

[0022] Core Reinforced 7 Core MgB 2 Preparation of superconducting wires:

[0023] (1) In a vacuum glove box, under the protection of argon with a mass purity of 99.999%, the magnesium powder, amorphous boron powder and doping powder are dosed according to the atomic number ratio of 1:1.95:0.05, and then mixed and ground to obtain the precursor powder ; The precursor powder is packed into the Nb / Cu composite tube, and then drawn to the target size with a pass processing rate of 30% and the cross-section is a hexagonal primary composite single-core wire with a side length of 3mm; the doped powder is Amorphous carbon; in the Nb / Cu composite tube, the Nb tube is the inner tube, the Cu tube is the outer tube, and the Nb tube is used as a barrier layer to prevent the interaction between the superconducting powder and the sheath material during heat treatment, and at the same time play a strengthening role; the primary composite single-core wire is processed into a hexagonal cross-...

Embodiment 2

[0029] Core Reinforced 7 Core MgB 2 Preparation of superconducting tape:

[0030] The preparation method of this example is the same as that of Example 1, the difference being that: the prepared wire diameter is 0.8mm core reinforced 7-core MgB 2 The superconducting wire is rolled with a pass reduction of 30% by flat roll rolling technology to obtain a core-reinforced 7-core MgB with a thickness of 0.3mm 2 superconducting tape.

Embodiment 3

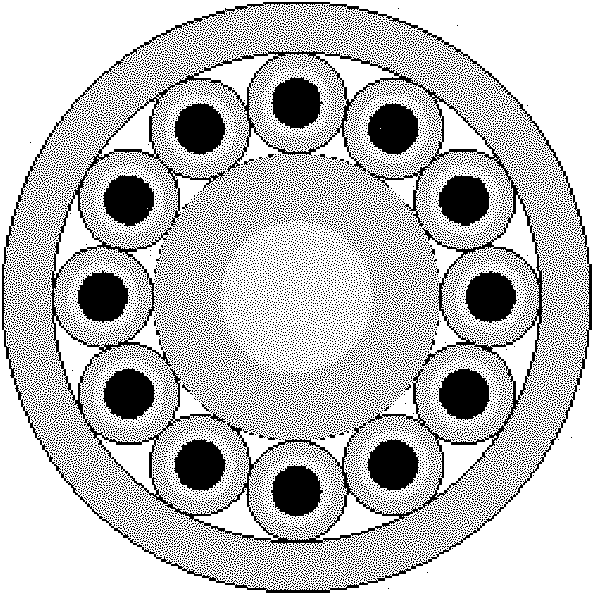

[0032] Core Reinforced 13 Core MgB 2 Preparation of superconducting tape:

[0033](1) In a vacuum glove box, under the protection of argon with a mass purity of 99.999%, the magnesium powder, amorphous boron powder and doping powder are dosed according to the atomic ratio of 1:1.9:0.1, and then mixed and ground to obtain the precursor powder ; The precursor powder is packed into the Nb / Cu composite tube, and then drawn to the target size with a pass processing rate of 20% and the cross-section is a circular primary composite single-core wire with a diameter of 9 mm; the doped powder is carbonized Titanium; in the Nb / Cu composite tube, the Nb tube is the inner layer tube, the Cu tube is the outer layer tube, and the Nb tube is used as a barrier layer to prevent the interaction between the superconducting powder and the sheath material during heat treatment, and at the same time play a role Strengthening effect: the primary composite single-core wire is processed into a circula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com