Method for synthesizing ZSM-5 zeolite

A ZSM-5, synthesis method technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of discharge of sodium sulfate-containing waste liquid, pollution of the environment, waste of resources, etc. , to achieve the effect of high yield per reactor, environmental protection and zero emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

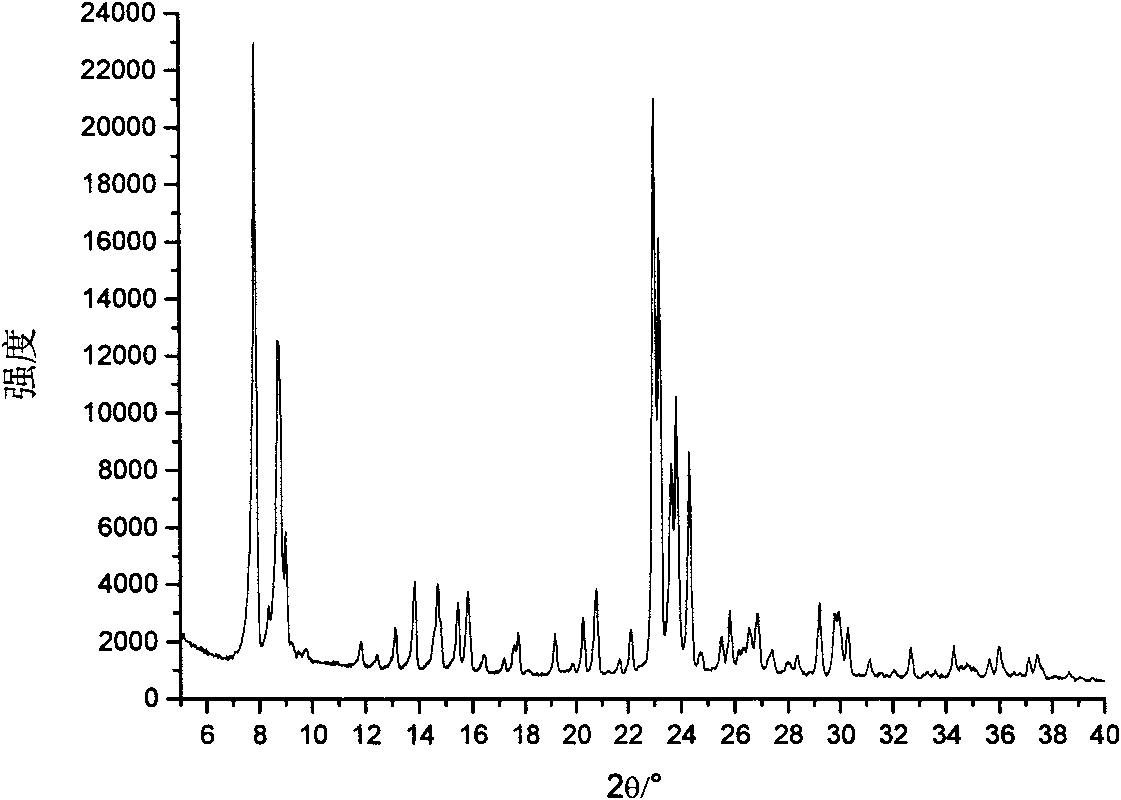

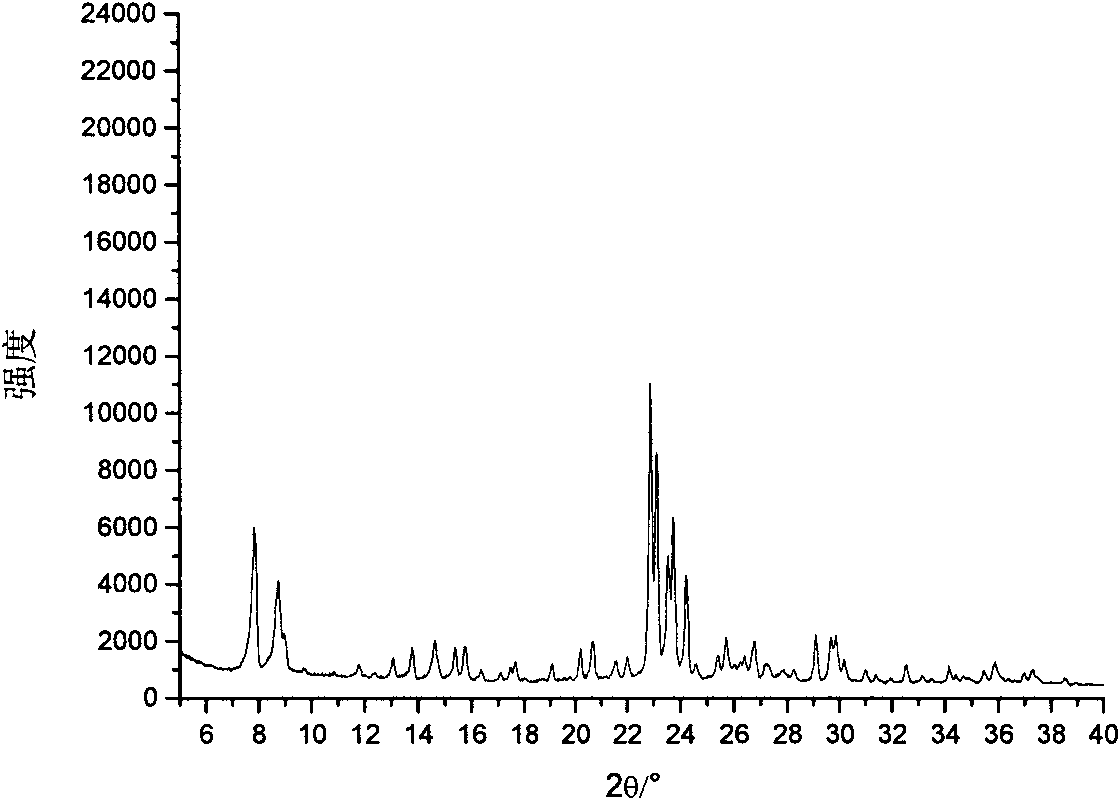

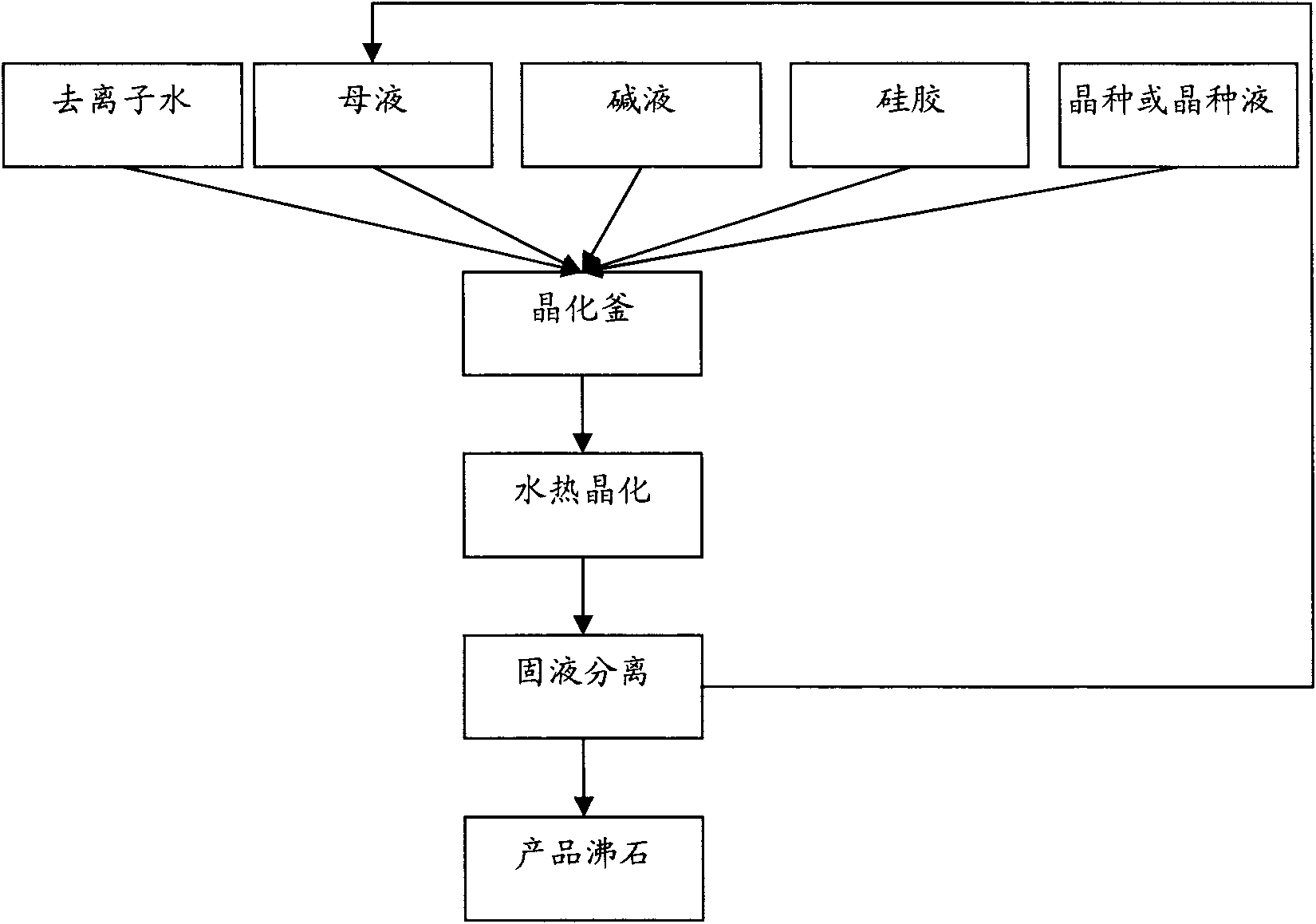

[0022] To the volume of 1m 3 Add 60 kg of deionized water, 5.1 kg of low bias, 10 kg of 20% by weight NaOH solution, 24.6 kg of coarse-pore silica gel and 2.4 kg of NaY zeolite in the crystallization kettle, and stir for 30 minutes to obtain a uniform gel. Dynamic crystallization was carried out at 180° C. for 17 hours, and the stirring speed of dynamic crystallization was 15 rpm. Then cool to room temperature and filter to obtain mother liquor and filter cake. The filter cake is washed and dried to obtain a solid product. The solid product is analyzed by X-ray diffraction to be a pure phase ZSM-5 zeolite with a relative crystallinity of 100%. In the present embodiment, the mol ratio between each component of reaction mixture is as follows: Na 2 O / SiO 2 =0.1:1, SiO 2 / Al 2 o 3 =50:1, H 2 O / SiO 2 =10:1. Seed / SiO 2 (weight ratio) = 0.08:1. Obtain 41 kilograms of mother liquor, SiO in mother liquor 2 The content is 5.97% by weight, Na 2 The O content is 2.20% by weig...

Embodiment 2

[0024] to 1m 3 Add 26 kilograms of deionized water, 41 kilograms of the mother liquor obtained in Example 1, 5.1 kilograms of low bias, 5.2 kilograms of 20% by weight NaOH solution, 21.9 kilograms of coarse-pore silica gel and 2.4 kilograms of NaY in the crystallization kettle, and stir for 30 minutes. A uniform gel was obtained, sealed, and dynamically crystallized at 180° C. for 12 hours, and the stirring speed of dynamic crystallization was 15 rpm. Then cool to room temperature, filter to obtain the mother liquor and filter cake, and the filter cake is washed and dried to obtain a solid product. The solid product was analyzed by X-ray diffraction to be a pure phase ZSM-5 zeolite with a relative crystallinity of 102%. In the present embodiment, the mol ratio between each component of reaction mixture is as follows: Na 2 O / SiO 2 =0.1:1, SiO 2 / Al 2 o 3 =50:1, H 2 O / SiO 2 =10:1. Seed / SiO 2 (weight ratio) = 0.08:1. Obtain 41 kilograms of mother liquor, SiO in mother ...

Embodiment 3

[0026] With embodiment 2, difference is to add the mother liquor that 41 kilograms of embodiment 2 obtains. In this example, the solid product is a pure-phase ZSM-5 zeolite with a relative crystallinity of 102%. The molar ratio between the components of the reaction mixture is as follows: Na 2 O / SiO 2 =0.1:1, SiO 2 / Al 2 o 3 =50:1, H 2 O / SiO 2 =10:1. Seed / SiO 2 (weight ratio) = 0.08:1. Obtain 41 kilograms of mother liquor, SiO in mother liquor 2 The content is 5.96% by weight, Na 2 The O content was 2.22% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com