Method for producing compound fertilizer by using fermentation glutamate extraction waste liquor

A glutamic acid and compound fertilizer technology, which is applied in the field of amino acid fermentation waste liquid treatment, can solve the problems of environmental pollution, inability to use anaerobic treatment, and low utilization rate of recycled resources, so as to overcome the low utilization rate of recycled resources and solve the problem of tail gas The effect of secondary pollution and high utilization rate of recycled resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

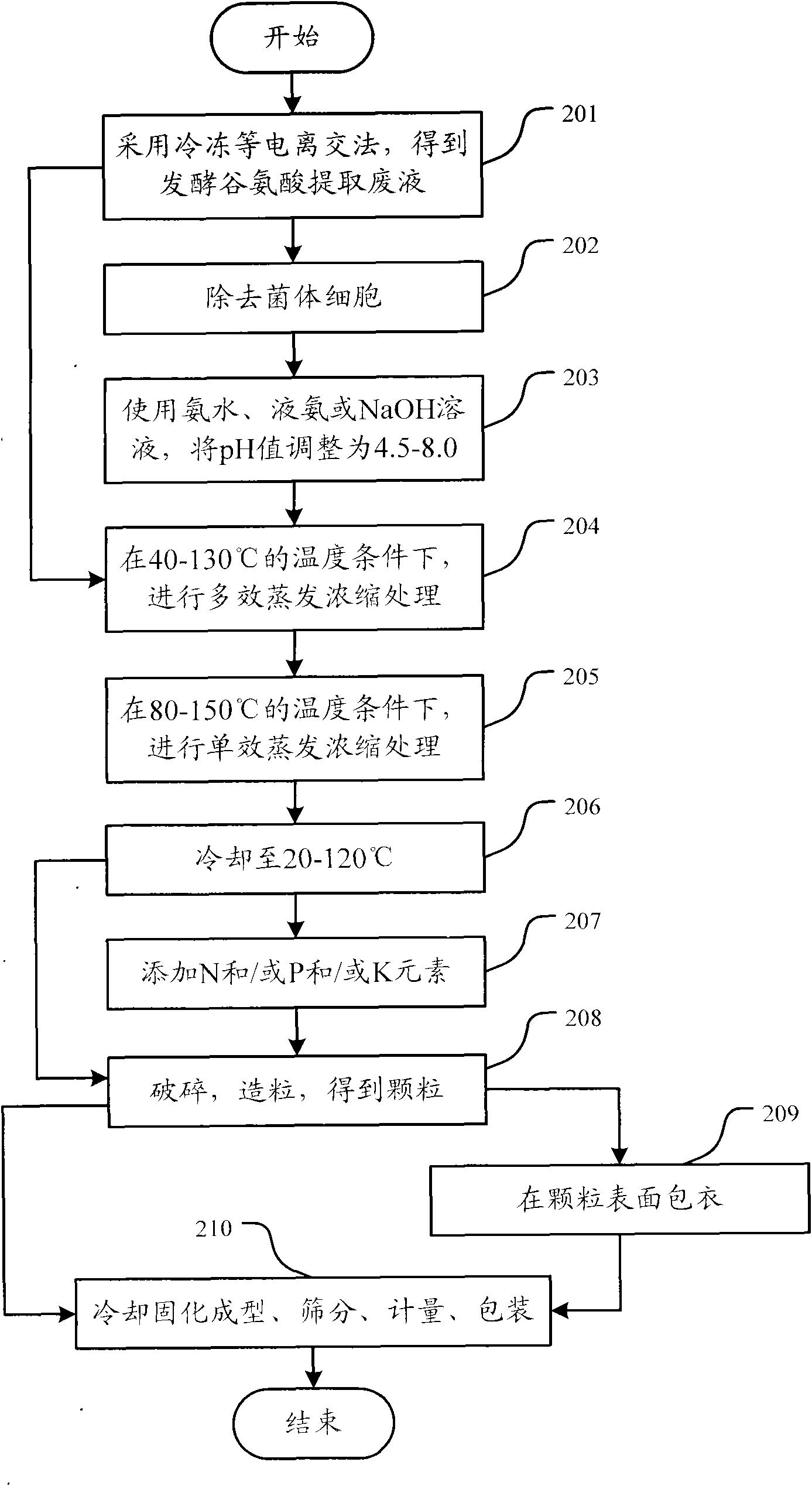

[0059] According to an embodiment of the present invention, a method for producing compound fertilizer by using fermentation glutamic acid to extract waste liquid is provided. Such as figure 2 As shown, this embodiment includes the following steps:

[0060] Step 201: Obtain the waste liquid of fermented glutamic acid extraction by freezing iso-ionization method;

[0061] In this embodiment, in step 201, the pH value of the fermentation glutamic acid extraction waste liquid is 3.5, and the weight (w) of solid matter accounts for 10% of the volume (v) of the fermentation glutamic acid extraction waste liquid;

[0062] Step 202: remove the bacterial cells; here, step 202 can be selected according to actual needs;

[0063] In this embodiment, you can choose not to perform this step;

[0064] Step 203: Using ammonia water, liquid ammonia or NaOH solution, adjust the pH value to 4.5-8.0;

[0065] In this embodiment, in step 203, liquid ammonia can be used to adjust the pH value...

Embodiment 2

[0082] Different from the first embodiment above, in this embodiment, if figure 2 Shown, utilize fermented glutamic acid to extract waste liquid to produce in the method for compound fertilizer, can comprise the following steps:

[0083] In step 201, the pH value of the fermentation glutamic acid extraction waste liquid is 1.5, and the weight (w) of solid matter accounts for 20% of the volume (v) of the fermentation glutamic acid extraction waste liquid;

[0084] In this embodiment, step 202 can be optionally executed;

[0085] In step 203, the pH value of the waste liquid extracted from fermented glutamic acid is adjusted to 4.5;

[0086] In step 204, after multi-effect evaporation and concentration treatment, the weight concentration of solids in the obtained concentrated slurry can reach 80%;

[0087] In step 205, after single-effect evaporation and concentration treatment, the weight concentration of solids in the obtained concentrated slurry can reach 90%;

[0088] In...

Embodiment 3

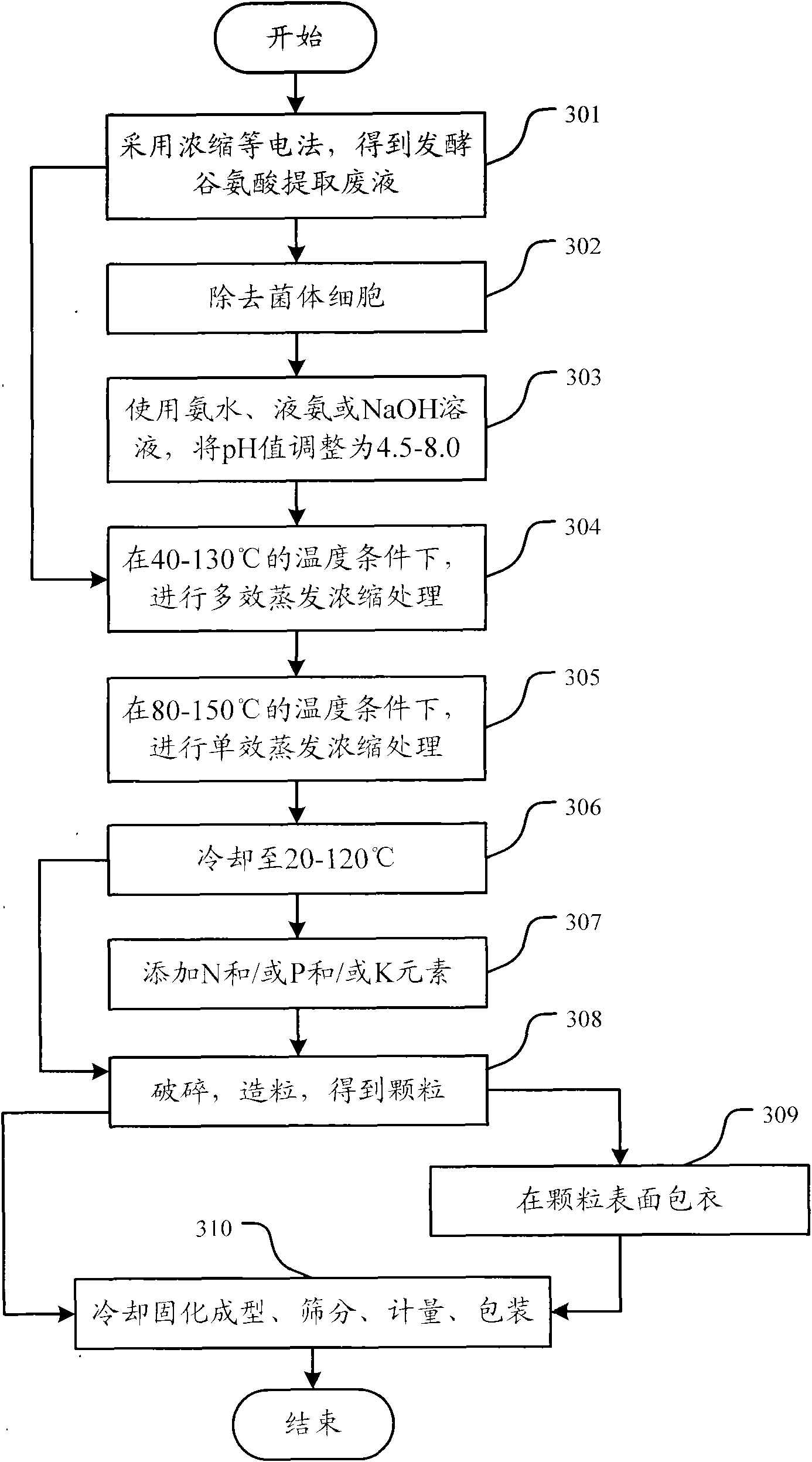

[0090] Different from the first and / or second embodiment above, in this embodiment, if figure 2 Shown, utilize fermented glutamic acid to extract waste liquid to produce in the method for compound fertilizer, can comprise the following steps:

[0091] In step 201, the pH value of the fermentation glutamic acid extraction waste liquid is 5.0, and the weight (w) of solid matter accounts for 5% of the volume (v) of the fermentation glutamic acid extraction waste liquid;

[0092] In step 203, adjust the pH value of the fermentation glutamic acid extraction waste liquid to 8.0;

[0093] In step 204, after multi-effect evaporation and concentration treatment, the weight concentration of solids in the obtained concentrated slurry can reach 50%;

[0094] In step 205, after single-effect evaporation and concentration treatment, the weight concentration of solids in the obtained concentrated slurry can reach 80%;

[0095] In step 206, the temperature of the concentrated slurry obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com