Catalyst for preparation of isobutene by isobutene dehydrogenation as well as preparation process and dehydrogenation process thereof

A catalyst and isobutane technology, applied in the field of dehydrogenation technology, can solve the problems of complicated catalyst preparation steps, unfavorable catalyst service life, easy carbon deposition and deactivation of the catalyst, etc., and achieve the effects of reducing preparation cost, simple method and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

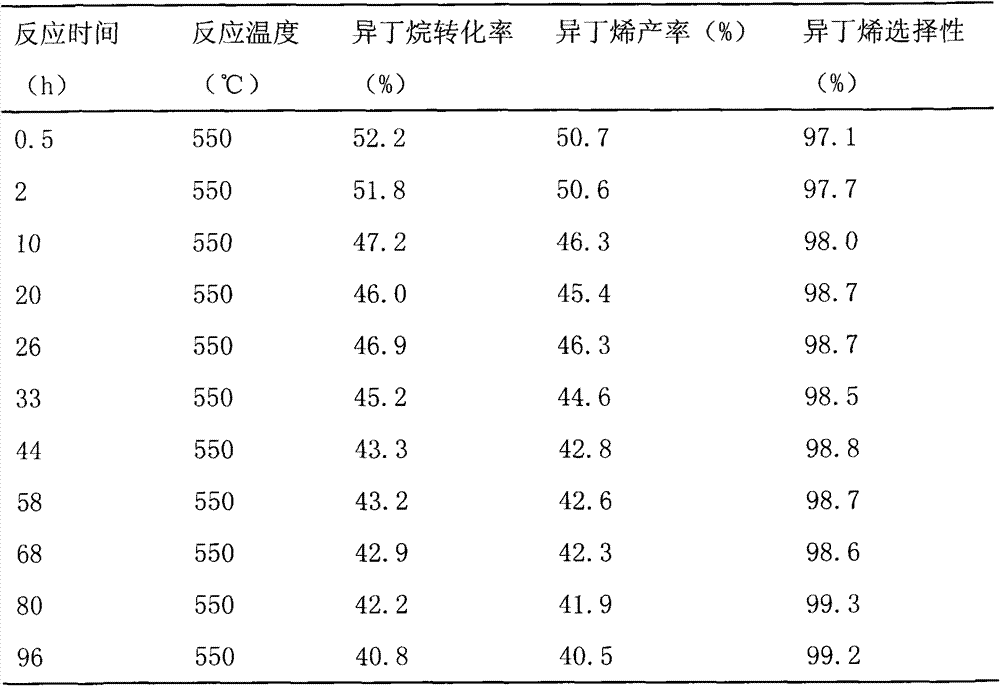

Embodiment 1

[0032] Catalyst-A" is composed of 0.4wt% Pt, 0.49wt% Sn (Pt:Sn=1:2), 1wt% K, and 1.73wt% Cl supported on alumina particles. The preparation method is as follows:

[0033] First take a certain amount of alumina particles, and then take a quantitative amount of SnCl dissolved in hydrochloric acid 2 Solution (as 0.49% Sn), quantitative H 2 PtCl 6 The solution (calculated as 0.4% Pt) is made into a mixed solution, and then a quantitative amount of K is added after the complex is formed. 2 CO 3 solution (1% K), and then diluted with hydrochloric acid to make the required volume. The alumina particles were immersed in the above solution and mixed evenly, then left to stand for 10 hours under room conditions, dried at 120°C for 12 hours, and then fired in a tube furnace at 500°C with 50ml / min air for 4 hours. Put 10ml of catalyst into the fixed bed reactor, at 480℃H 2 (150ml / min) reduction under normal pressure in air flow for 2 hours. Then the temperature was raised to 550°C t...

Embodiment 2

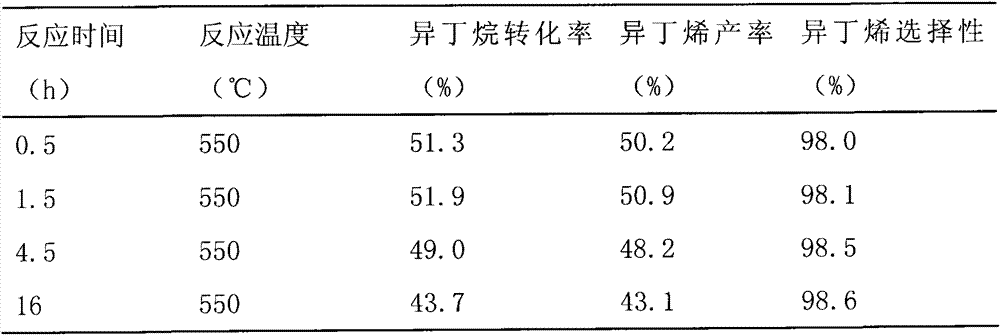

[0040] Catalyst "B" is composed of 0.4wt% Pt, 0.6wt% Sn (Pt: Sn=1: 2.5), 1wt% K, and 1.73wt% Cl supported on alumina particles. The preparation method is the same as in Example 1, and the reaction conditions are the same as in the example 1.

[0041] Catalyst "B" reaction performance as shown in Table 3

[0042] Table 3: Catalyst B isobutane dehydrogenation reaction performance

[0043]

Embodiment 3

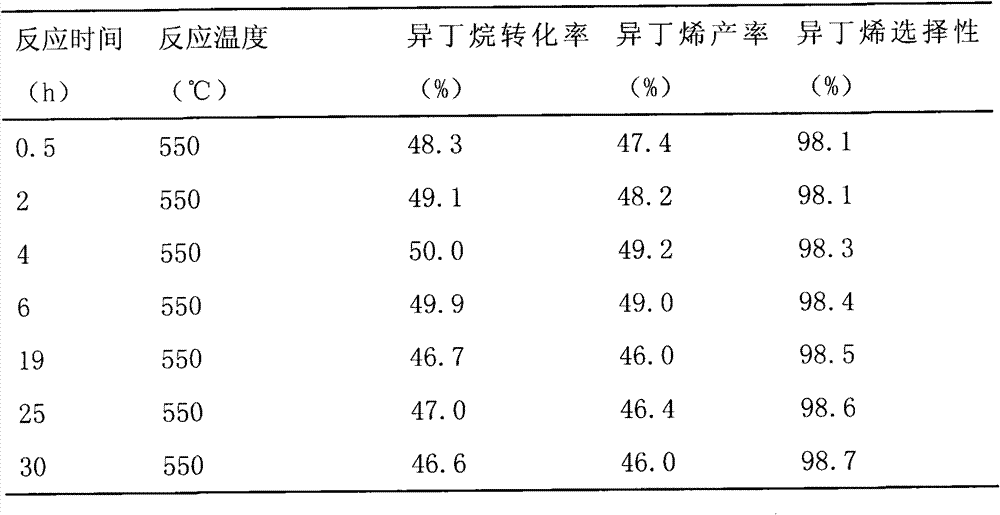

[0044] Embodiment 3: Catalyst " C " is composed of 0.4wt% Pt, 0.73wt% Sn (Pt: Sn=1: 3), 1wt% K, 1.73wt% Cl loaded on the alumina particle, preparation method is the same as example 1, Reaction feed composition is the same as example 1.

[0045] Catalyst "C" reaction performance as shown in Table 4

[0046] Table 4: Catalyst C isobutane dehydrogenation reaction performance

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com