Method for regenerating activity of deactivated ferritic catalyst

A catalyst and iron-based technology, applied in the field of deactivation and regeneration of iron-based catalysts, can solve the problems of short service life of regenerated catalysts, undiscovered, hidden dangers of explosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

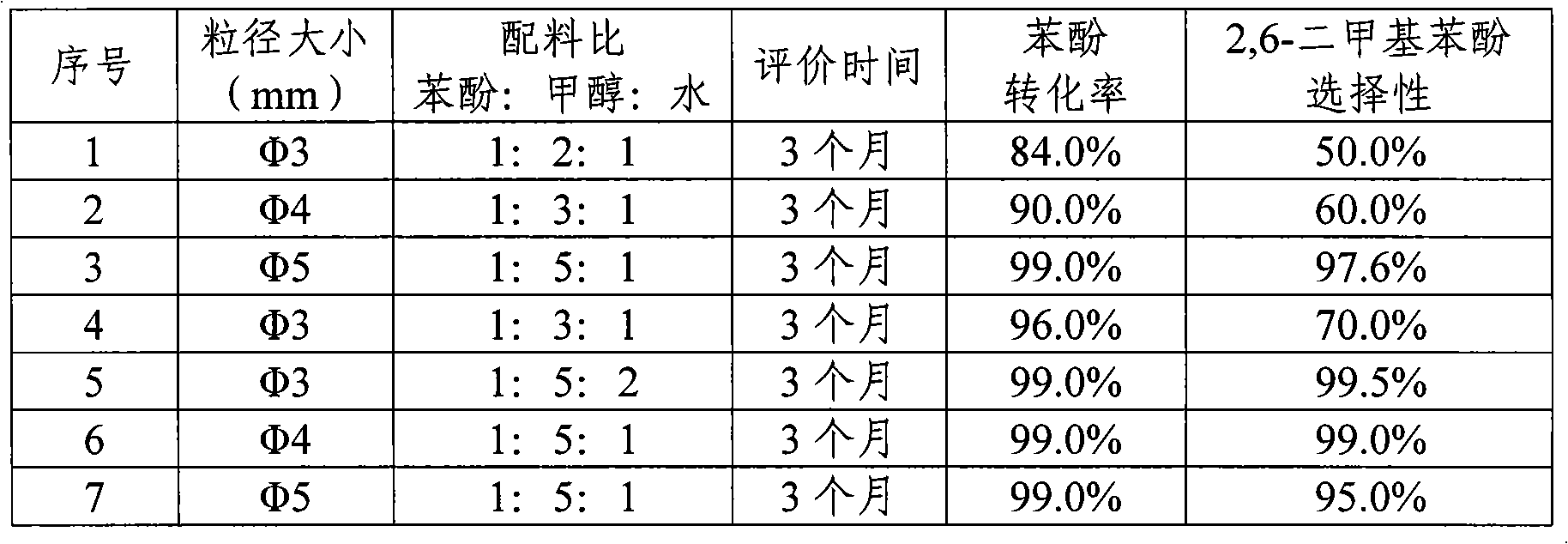

Examples

Embodiment 1

[0033] Take 200 grams of deactivated catalyst, put it into a muffle furnace, and roast it with air at 475° C. to remove the coke. Keep the air flow rate at 20 L / h and keep it warm for 4 hours. Smash it for later use.

[0034] Get 143 grams of above-mentioned pulverized catalysts, put into the 2000ml there-necked flask that is stirred and heated with a condenser, add 1000 grams of 36% nitric acid and 300 grams of 30% hydrochloric acid, heat up under stirring, and keep warm at 100° C. for 8 hours.

[0035] The content of nitric acid in the reaction liquid is detected by the method of acid-base neutralization, and when the content reaches 15%, the stirring reaction is continued for 2 hours. Stirring and heating were discontinued and allowed to stand for 48 hours.

[0036] After the temperature is cooled to room temperature, filter, and detect the content of iron, chromium, sodium and indium in the filtrate by atomic absorption method, and convert it into the mass percentage cont...

Embodiment 2

[0043] Take 200 grams of deactivated catalyst, put it into a muffle furnace, and roast it with air at 450° C. to remove the coke. Keep the air flow rate at 20 L / h and keep it warm for 8 hours. Smash it for later use.

[0044]Get 143 grams of above-mentioned pulverized catalysts, put into the 2000ml there-necked flask that is stirred and heated with a condenser, add 1210 grams of 36% nitric acid and 300 grams of 30% hydrochloric acid, heat up under stirring, and keep warm at 150° C. for 4 hours.

[0045] The content of nitric acid in the reaction liquid is detected by the method of acid-base neutralization, and when the content reaches 15%, the stirring reaction is continued for 1.5 hours. Stop stirring and heating, let stand for 50 hours.

[0046] After the temperature is cooled to room temperature, filter, and detect the content of iron, chromium, sodium and indium in the filtrate by atomic absorption method, then supplement the corresponding amount according to the method o...

Embodiment 3

[0049] Take 200 grams of deactivated catalyst, put it into a muffle furnace, and roast it with air at 460° C. to remove the coke. Keep the air flow rate at 20 L / h and keep it warm for 10 hours. Smash it for later use.

[0050] Take 143 grams of the above pulverized catalyst, put it into a 1500ml there-necked flask with condenser stirring and heating, add 600 grams of aqua regia, heat up under stirring, and keep warm at 100°C for 8 hours.

[0051] The content of aqua regia in the reaction solution was detected by the method of acid-base neutralization, and when the content reached 15%, the stirring reaction was continued for 2.5 hours. Stirring and heating were stopped and allowed to stand for 46 hours.

[0052] After the temperature is cooled to room temperature, filter, and detect the content of iron, chromium, sodium and indium in the filtrate by atomic absorption method, then supplement the corresponding amount according to the method of Example 1, and operate in the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com