Method for calcining and whitening feldspar micropowder

A technology of feldspar powder and feldspar, applied in the direction of non-metallic elements, etc., to achieve the effect of simple process, easy operation, and widening application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

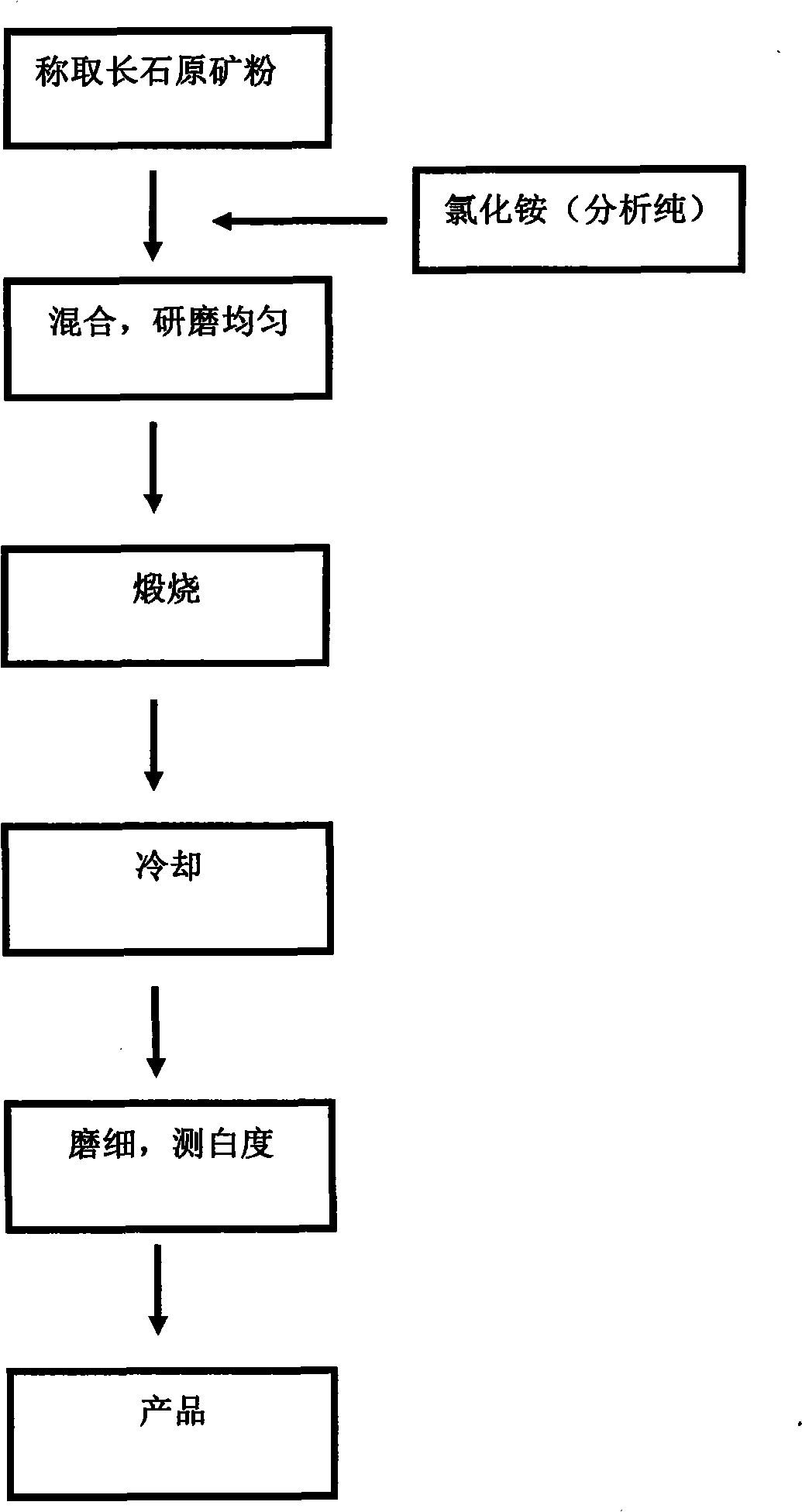

Method used

Image

Examples

Embodiment 1

[0018] Mix 20g of feldspar raw ore powder (78% whiteness, 800 mesh) with 2g of ammonium chloride, grind it evenly and pour it into a porcelain crucible. It was calcined at ℃ for 2 hours, and the calcined product was taken out and cooled, and its whiteness was measured to be 92% after grinding.

Embodiment 2

[0020] Mix 20g of feldspar raw ore powder (76% whiteness, 325 mesh) with 1g of ammonium chloride, grind it evenly, pour it into a porcelain crucible, put the porcelain crucible into a muffle furnace, and heat up to 900°C with the furnace. It was calcined at ℃ for 2 hours, and the calcined product was taken out and cooled, and its whiteness was measured to be 88% after grinding.

Embodiment 3

[0022] Mix 20g feldspar raw ore powder (76% whiteness, 325 mesh) with 0.85g ammonium chloride, grind evenly and pour it into a porcelain crucible, put the porcelain crucible into a muffle furnace and heat up to 900°C with the furnace. Calcined at 900°C for 1 hour, the calcined product was taken out and cooled, and its whiteness was measured to be 86% after grinding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com