Ash-free antirust additive for industrial lubricant and preparation method thereof

A technology of ashless antirust agent and lubricating oil, which is applied in the preparation of additives, organic compounds, petroleum industry, etc. It can solve the problems of high acid value, antirust effect not as good as alkenyl succinic acid, corrosion of metal parts, etc. , to achieve the effect of low acid value, good oil solubility, anti-rust performance and good anti-emulsification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0018] Weigh 284.5 g (1 mol) of stearic acid and add it to a 1000 ml three-neck bottle, and then add 300-500 ml of 200 # Solvent oil (Lanzhou Oil Refinery, d 20 =0.792 g / cm3, in accordance with GB1884 specifications), stir and heat to reflux state, and then slowly add 77.3 g (1 mol) of dimethanolamine dropwise for esterification reaction until the theoretical amount of water produced by the reaction is removed. After the reaction, under the condition of room temperature-160℃ / 0.029-0.1MPa, 200 # Solvent oil, the esterification reaction product RHY702-1 of stearic acid and dimethanolamine was prepared, the appearance was light red liquid, and the yield was 92%.

example 2

[0020] Weigh 281 grams (about 1 mole) of oleic acid into a 1000 ml three-neck bottle, and then add about 500 ml of 120 # Solvent oil (Lanzhou Oil Refinery, d 20 =0.694 g / cm3, in line with GB1884 specifications), stir and heat to reflux state, and then add 119.1 g (1.0 mol) of triethanolamine in batches for esterification reaction until the theoretical amount of water produced by the reaction is removed. After the reaction, under the condition of room temperature-120℃ / 0.029-0.1MPa, 120 # Solvent oil, the esterification reaction product RHY702-2 of oleic acid and triethanolamine is prepared, and the appearance is yellow viscous liquid, and the yield is 86%.

example 3

[0022] Weigh 200.4 g (about 1 mol) of lauric acid into a 1000 ml three-neck bottle, and then add about 500 ml of 120 # Solvent oil (Lanzhou Oil Refinery, d 20 =0.694 g / cm3, in line with GB1884 specifications), stir and heat up to reflux, and then slowly add 191.6 g (1 mol) of tripropanolamine dropwise for esterification reaction until the theoretical amount of water produced by the reaction is removed. After the reaction, under the condition of room temperature-120℃ / 0.029-0.1MPa, 120 # Solvent oil, the esterification reaction product RHY702-3 of lauric acid and tripropanolamine was prepared, the appearance was reddish brown liquid, and the yield was 91%.

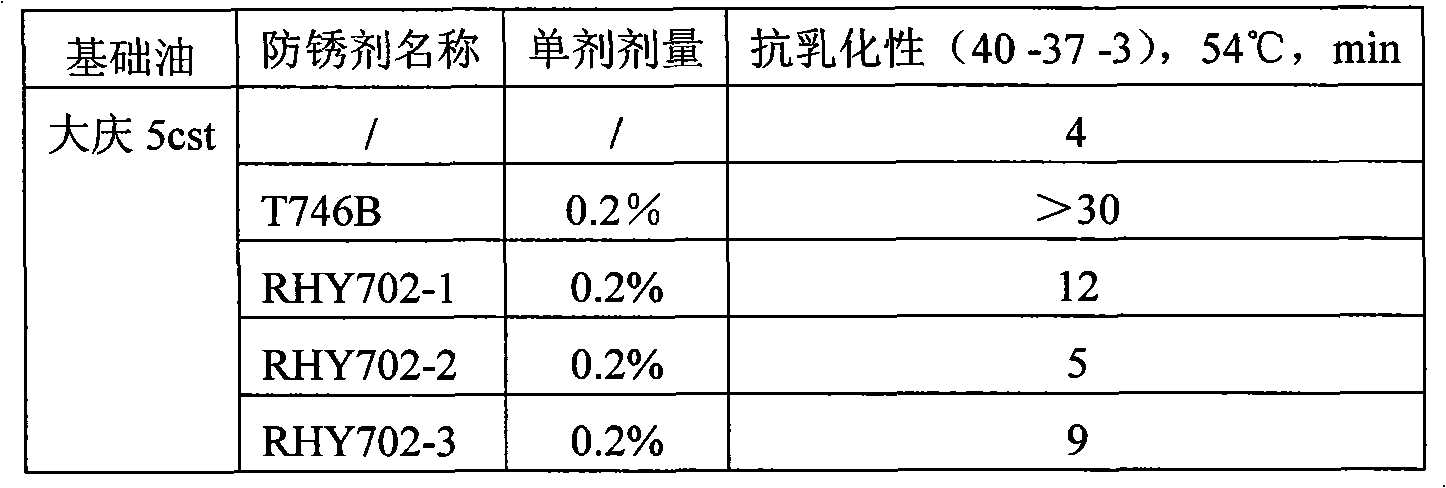

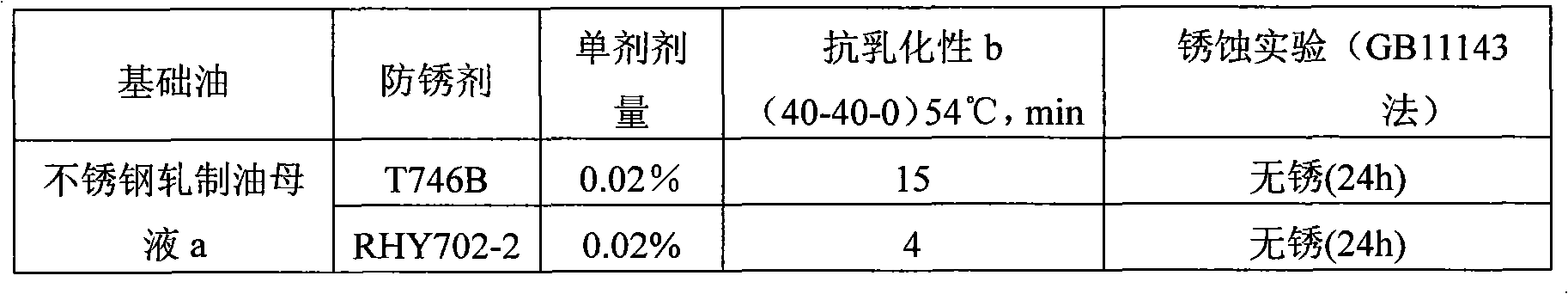

[0023] The main properties of the three ester rust inhibitors are shown in Table 1.

[0024] Table 1

[0025] Instance

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com