Method for preparing inorganic/organic composite microspheres

A composite microsphere and organic technology, applied in the field of composite materials, can solve the problems of nanoparticle leakage and achieve the effects of good repeatability, uniform distribution and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

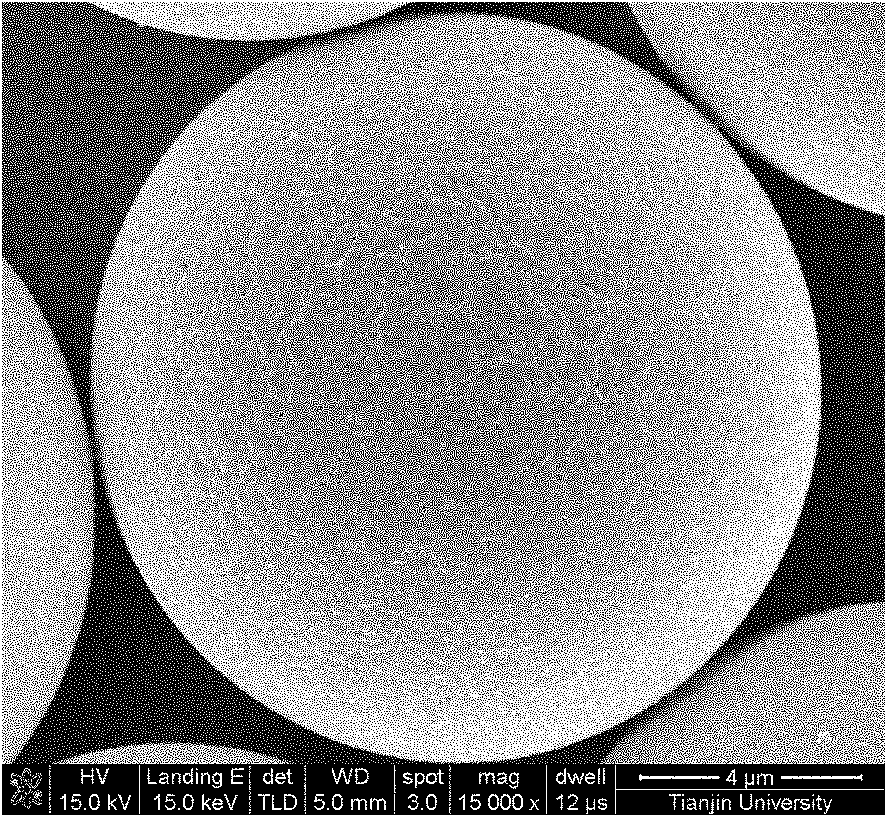

[0028] Step 1, weighing 30 mg of mesoporous polystyrene microspheres with an average particle size of 15 μm and a degree of crosslinking of 100%, such as figure 1 As shown; Measure 100 μL of CdSeTe quantum dots with an emission wavelength of 588nm; add the weighed microspheres into 6mL of hexadecane, and disperse evenly by ultrasonic; add the weighed quantum dots into 3mL of chloroform, and disperse evenly by ultrasonic ; Mix the two systems evenly and add them to a three-necked flask; install the air condensation device, ventilation device, and heating device; use a heating pot to raise the temperature, and keep the temperature at 50°C for 90 minutes;

[0029] Step 2, heating the reaction system to 180°C;

[0030] Step 3: observe that there is no reflux of chloroform, keep warm for 10 minutes, remove the heating device, rapidly cool down, and centrifuge and wash 4 times to obtain fluorescent microspheres.

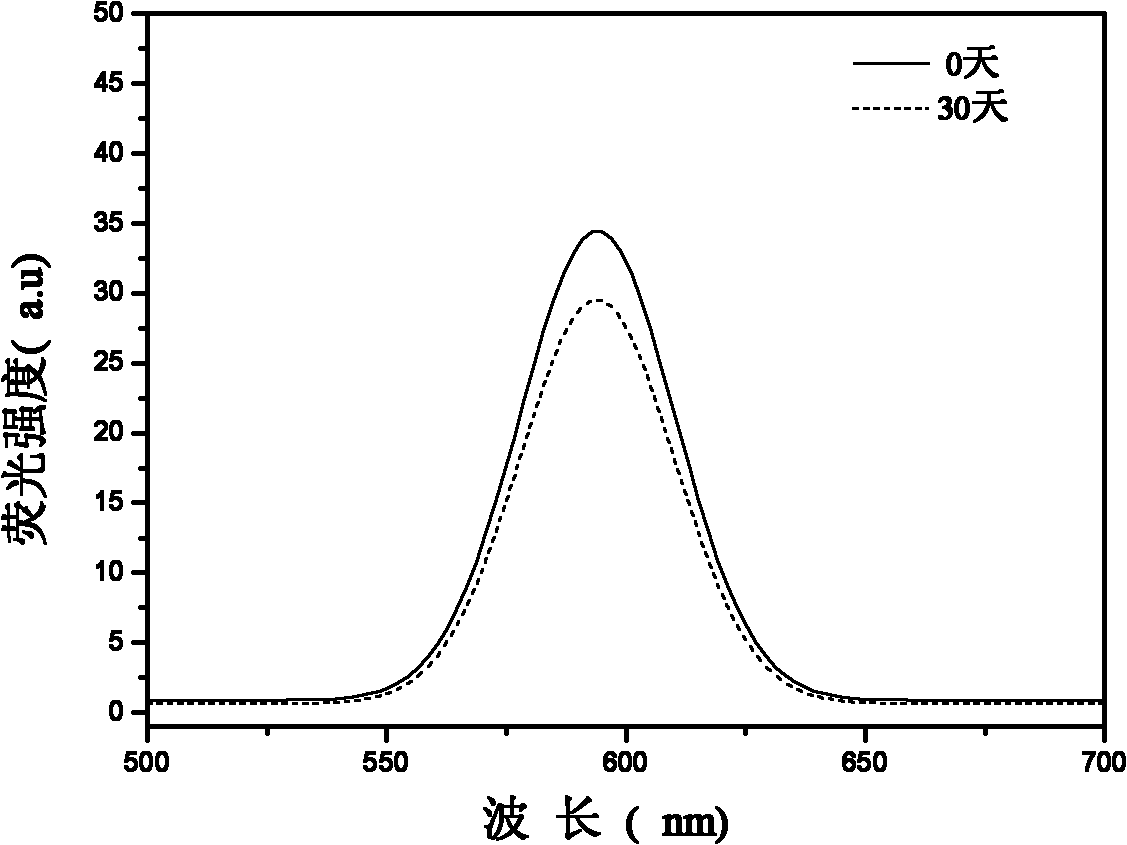

[0031] Such as figure 2 , is the fluorescence spectrum of the quan...

Embodiment 2

[0033] Step 1, take 5 mg of polymethyl methacrylate microspheres with an average particle size of 1 μm and a crosslinking degree of 5% and 20 μL of CdSe quantum dots with an emission wavelength of 541 nm, and add the weighed microspheres to 3 mL of hexadecane, Ultrasonic dispersion is uniform; add the measured quantum dots to 1mL of cyclohexane, and ultrasonic dispersion is uniform; mix the two systems evenly and add them to a three-necked flask; install the air condensation device, ventilation device, and heating device; Use a heating pot to raise the temperature, and keep it warm at 60°C for 30 minutes; Step 2, raise the temperature of the reaction system to 140°C;

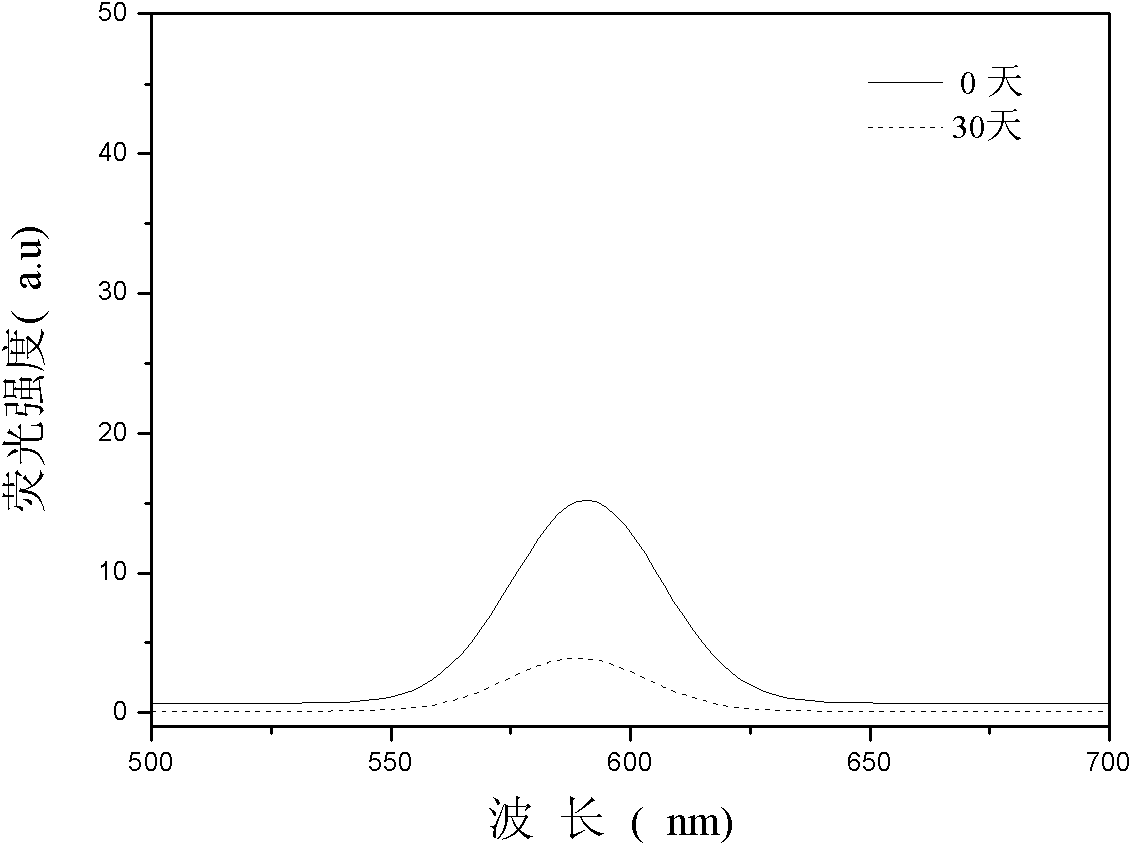

[0034] Step 3: observe without cyclohexane reflux, keep warm for 10 minutes, remove the heating device, rapidly cool down, centrifuge and wash 4 times to obtain fluorescent microspheres. Such as Figure 4 As shown, the fluorescent emission peak position of the prepared quantum dot fluorescent microspheres is at...

Embodiment 3

[0036] Step 1, take 20 mg of polyethyl methacrylate microspheres with an average particle size of 10 μm and a crosslinking degree of 20% and 60 μL of CdSe / ZnS quantum dots with an emission wavelength of 650 nm, and add the weighed microspheres to 6 mL of octadecane In olefin, the ultrasonic dispersion is uniform; the measured quantum dots are added to 4mL of cyclohexane, and the ultrasonic dispersion is uniform; the two systems are mixed evenly and then added to a three-necked flask; the air condensing device, ventilation device, and Heating device; use a heating pot to raise the temperature and keep it warm at 60°C for 60 minutes;

[0037] Step 2, heating the reaction system to 140°C;

[0038] Step 3: observe without cyclohexane reflux, keep warm for 10 minutes, remove the heating device, rapidly cool down, centrifuge and wash 4 times to obtain fluorescent microspheres. Such as Figure 5 As shown, the fluorescent emission peak position of the prepared quantum dot fluorescent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com