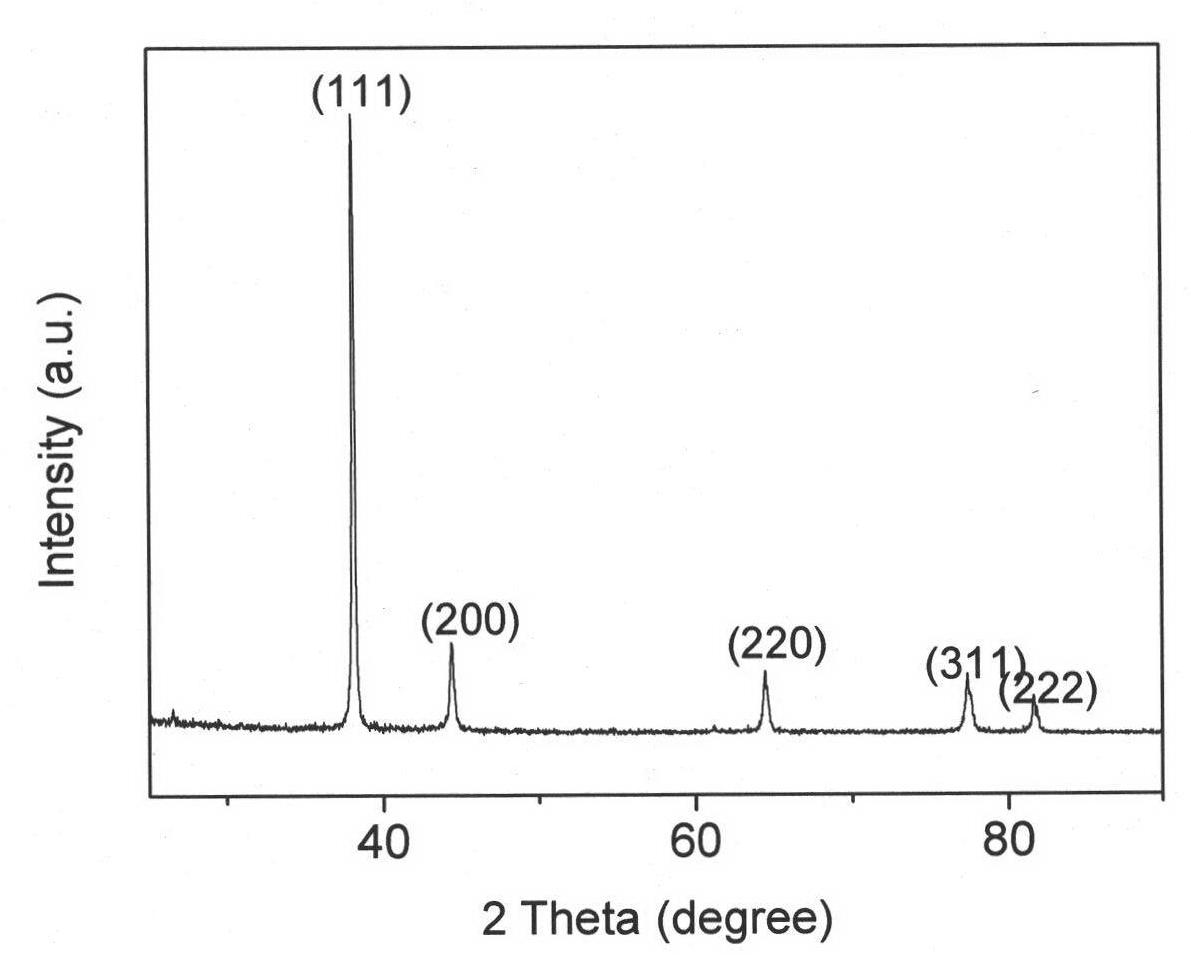

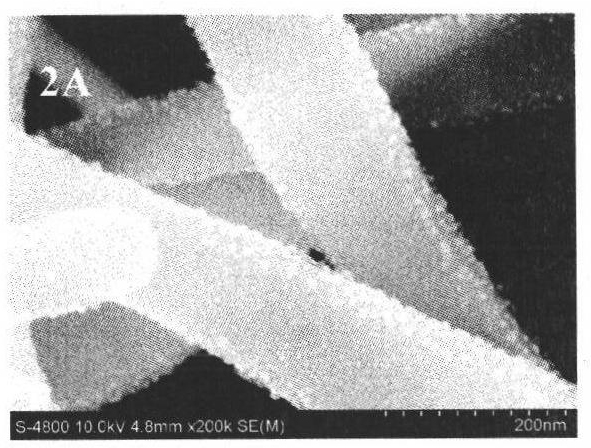

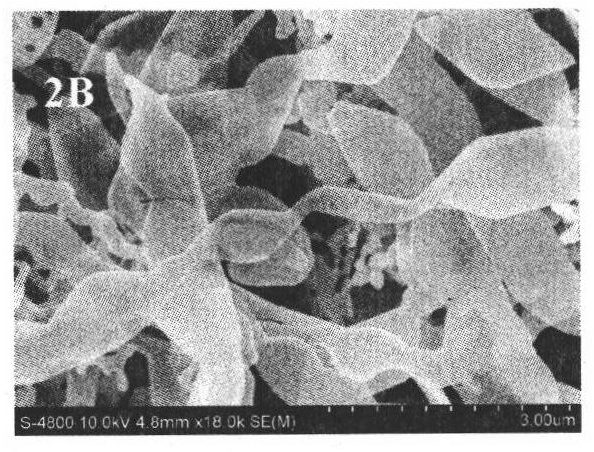

Preparation method of silver nanobelts

A silver nanometer and nanometer technology is applied in the field of preparation of silver nanobelts, which can solve the problems of cumbersome preparation process, low yield, and unfavorable large-scale industrial application of silver nanobelts, and achieves controllable morphology, uniform size, and large application. Advantages and Effects of Industrialization Prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Silver nitrate and aminoanisole are mixed in an aqueous solution, and dissolved by stirring or ultrasonic waves to obtain a uniform mixed solution, wherein the mass concentration of silver nitrate solution is 3%, and the volume concentration of aminoanisole is 0.25% ;

[0022] (2) Put the mixed solution in step (1) into an autoclave and seal it, the reaction temperature is 180°C, and the reaction time is 10 hours;

[0023] (3) After cooling, the target solid product is obtained by filtering or centrifuging.

[0024] (4) The reaction product was washed with absolute ethanol and pure water to remove possible impurities to obtain product A.

Embodiment 2

[0026] The mass concentration of the silver nitrate solution is 3%, the volume concentration of anisole is 0.5%, the reaction temperature is 180° C., and the reaction time is 10 hours. The reaction product can be washed with absolute ethanol and pure water to remove possible impurities to obtain product B. (Others are the same as embodiment 1)

Embodiment 3

[0028] The mass concentration of the silver nitrate solution is 3%, the volume concentration of anisole is 0.75%, the reaction temperature is 180° C., and the reaction time is 10 hours. The reaction product can be washed with absolute ethanol and pure water to remove possible impurities to obtain product C. (Others are the same as embodiment 1)

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com