Low contamination, low energy beamline architecture for high current ion implantation

An ion implantation system, ion beam technology, applied in circuits, discharge tubes, electrical components, etc., can solve problems such as influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is now described with reference to the drawings, in which like reference numerals are used to refer to like elements, and in which structures illustrated are not necessarily drawn to this example.

[0029] The main aspect of the invention is to facilitate the realization of low pollution low energy beamline structures for high current injection.

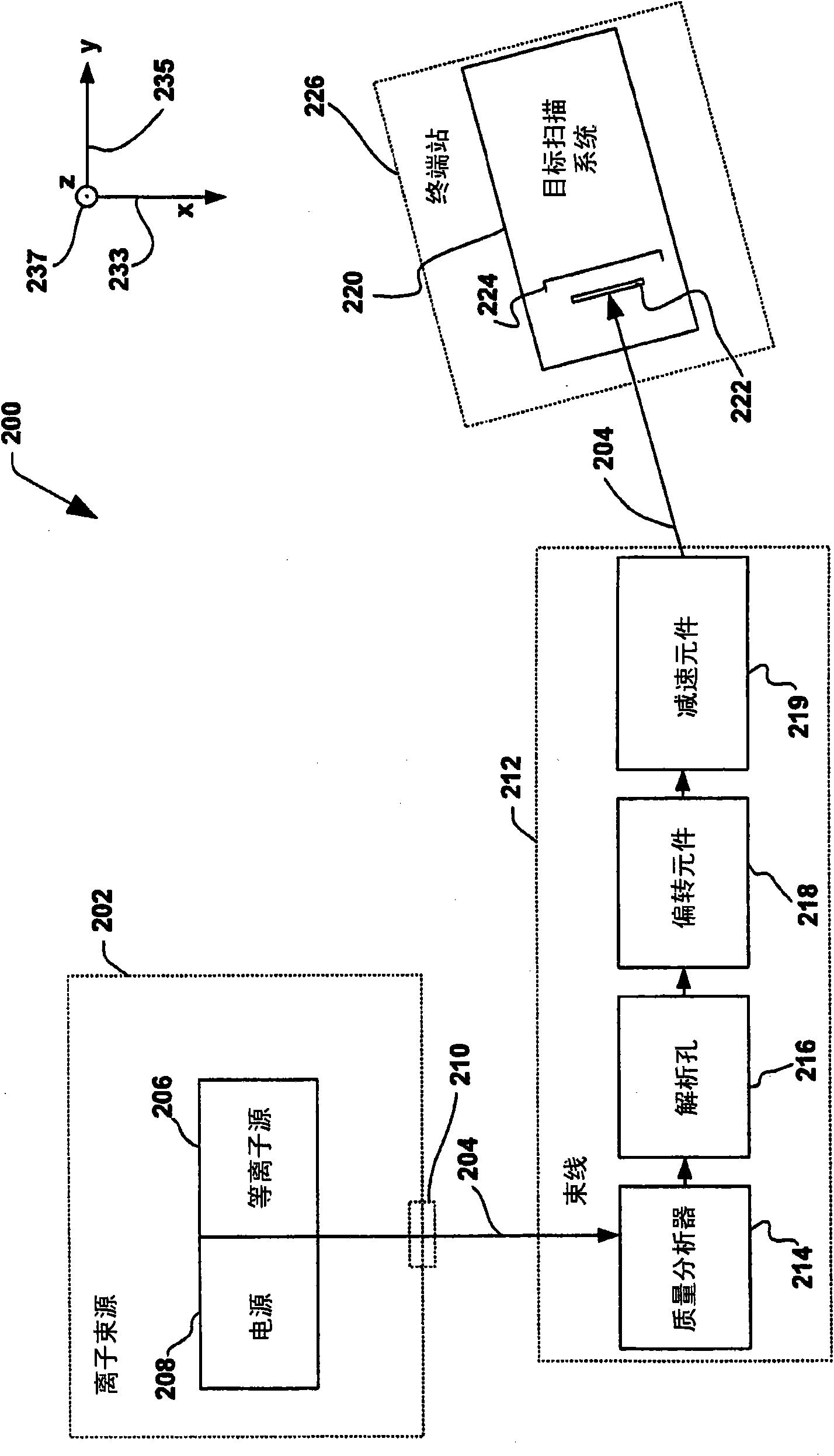

[0030] First, refer to figure 2 , which discloses a first embodiment of the present invention to provide an ion implantation system 200 comprising an ion source 202 for generating (eg pencil beam, ribbon beam, etc.) an ion beam 204 along a longitudinal beam path. The ion beam source 202 includes a plasma source 206 with an associated power supply 208 and an extraction device 210 . The extraction device can be of any design, by means of which it is possible, for example, to extract an elongated ribbon-shaped ion beam 204 with a large aperture ratio. The following examples are provided to more fully illus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com