Wet refractory mortar and preparation method thereof

A refractory mud, wet technology, applied in the field of refractory mud, can solve the problems of increasing the mortar gap and unsaturation of the product, polluting the environment, and short bonding time, etc., to achieve reduced saturated vapor pressure, stable chemical properties, and reduced water evaporation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

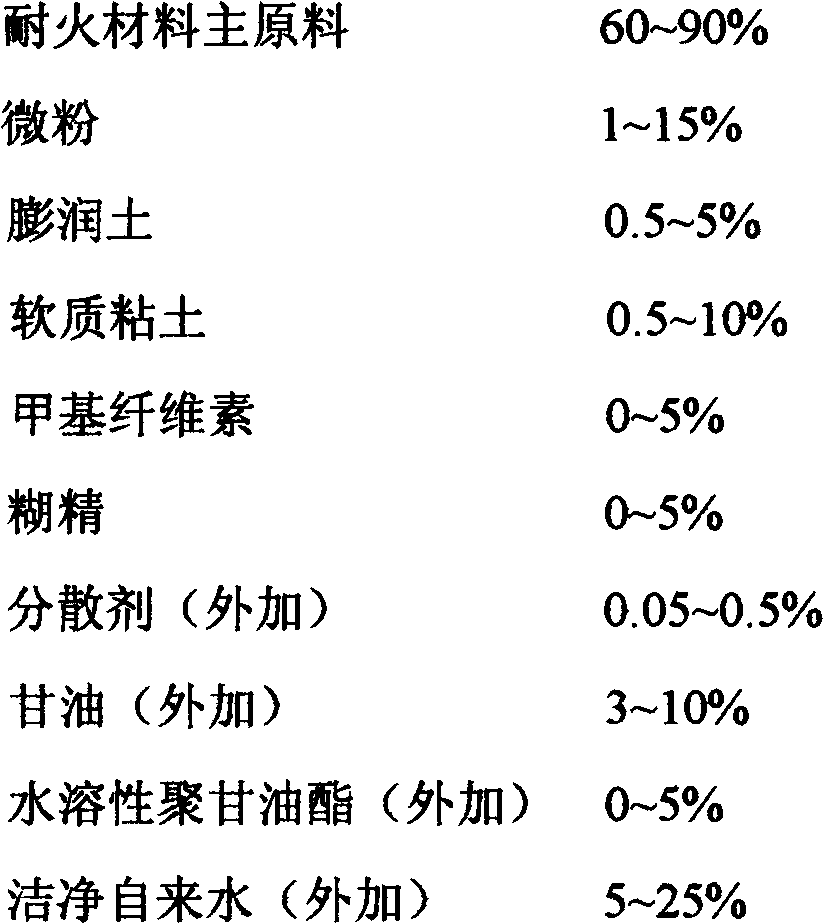

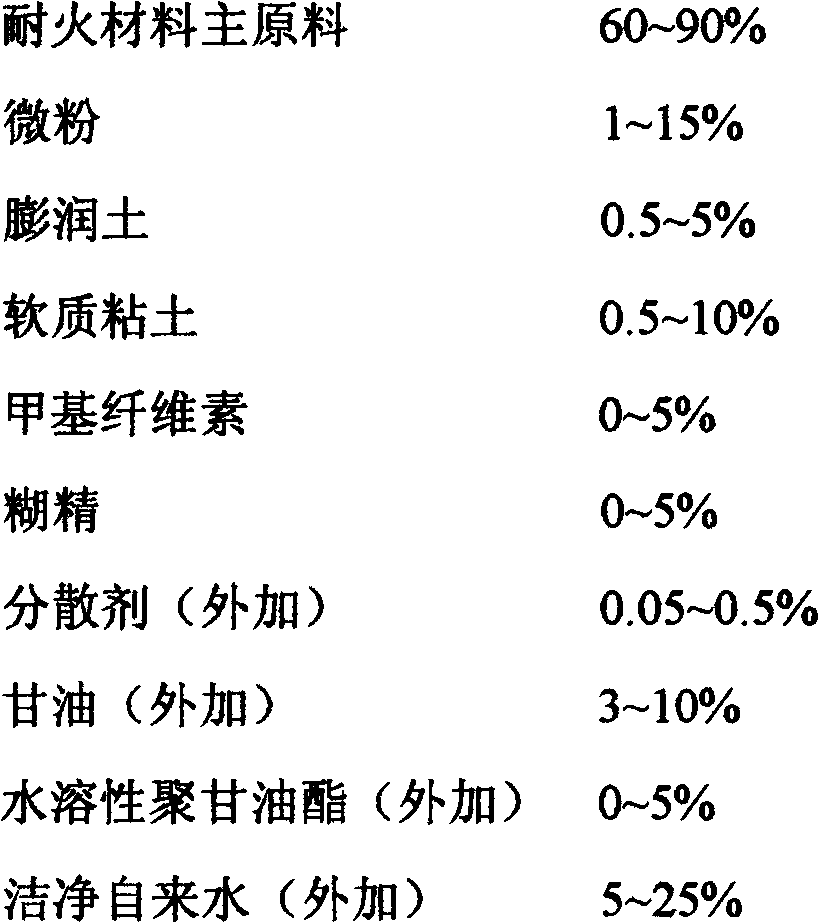

Method used

Image

Examples

Embodiment 1

[0046] Production of high alumina wet refractory mud with high alumina material as the main raw material:

[0047] (1) The component weight percents that are used to prepare polyglycerol ester glycerin solution are: polyglycerol ester 20%, glycerin 80%, pour in the plastic bucket after the preparation in proportion, make polyglycerol ester glycerol solution after fully dissolving by stirring ;

[0048] (2) The weight percentages used to prepare refractory mud raw materials are: kyanite-80 mesh 20%, GAL-g8 high alumina bauxite-200 mesh 60%, fused white corundum-320 mesh 10%, active SiO 2 Micropowder 3%, bentonite 2.5%, soft clay 3%, methylcellulose 1%, dextrin 0.5%, sodium tripolyphosphate (additional) 0.2%. The above raw materials are prepared according to the ratio and mixed evenly in a forced mixer to obtain a dry powder semi-finished product;

[0049] (3) Add clean tap water in an amount of 18% of the weight of the dry powdery semi-finished product, and forcefully knead for...

Embodiment 2

[0054] Production of corundum-based wet refractory mud with corundum as the main raw material:

[0055] (1) The component weight percents that are used to prepare polyglycerol ester glycerin solution are: polyglycerol ester 20%, glycerin 80%, pour in the plastic bucket after the preparation in proportion, make polyglycerol ester glycerol solution after fully dissolving by stirring ;

[0056] (2) The weight percentages of raw materials used to prepare refractory mud are: 50% of fused white corundum-180 mesh, 25% of fused white corundum-320 mesh, 4% of quartz sand-120 mesh, 2.5% of bentonite, and 4% of soft clay %, active α-Al 2 o 3 Micropowder 8%, chromium oxide green 5%, methyl cellulose 1%, dextrin 0.5%, calcium lignosulfonate (additional) 0.3%, according to the above proportions, mix evenly with a forced mixer to obtain a dry powder semi-finished products;

[0057] (3) Add clean tap water in an amount of 14% of the weight of the dry powdery semi-finished product, and for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com