Anionic-nonionic complex gasified coal water slurry additive

An anionic and non-ionic technology, applied in the gasification of granular/powdered fuels, petroleum industry, liquid carbon-containing fuels, etc., can solve the problems of limited universality of coal-water slurry additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

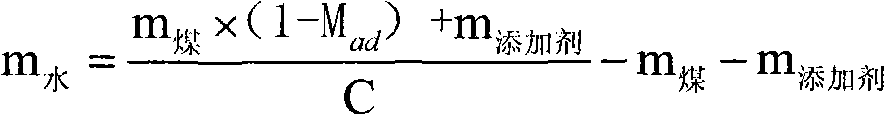

Method used

Image

Examples

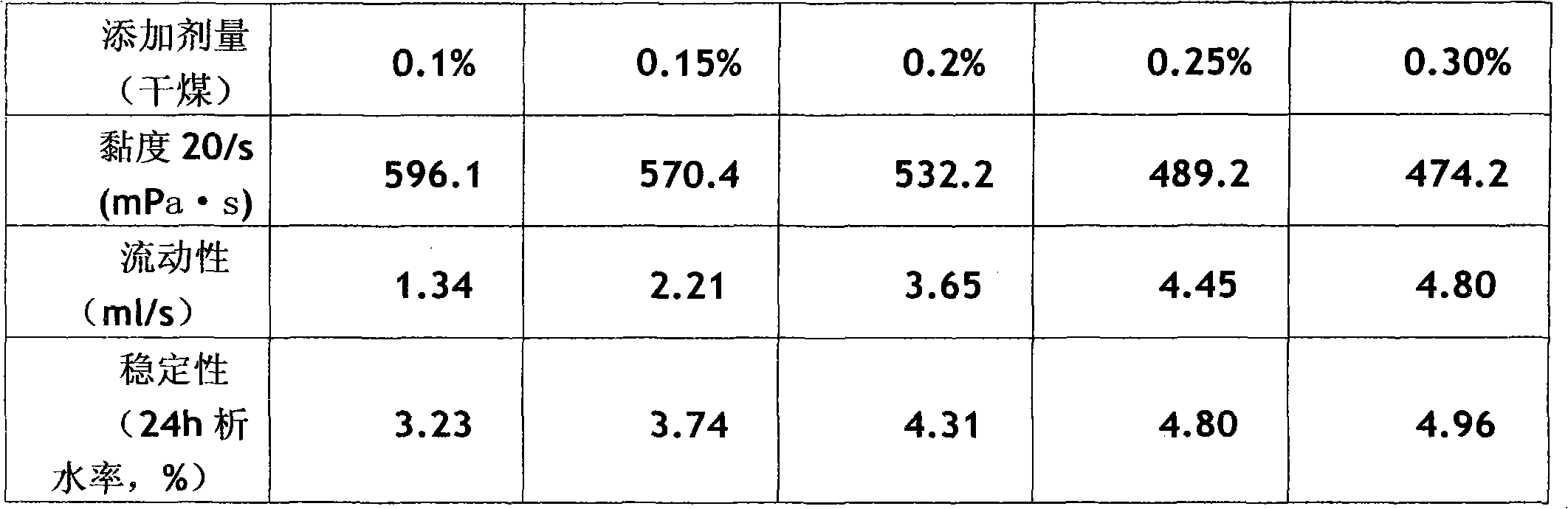

Embodiment 1

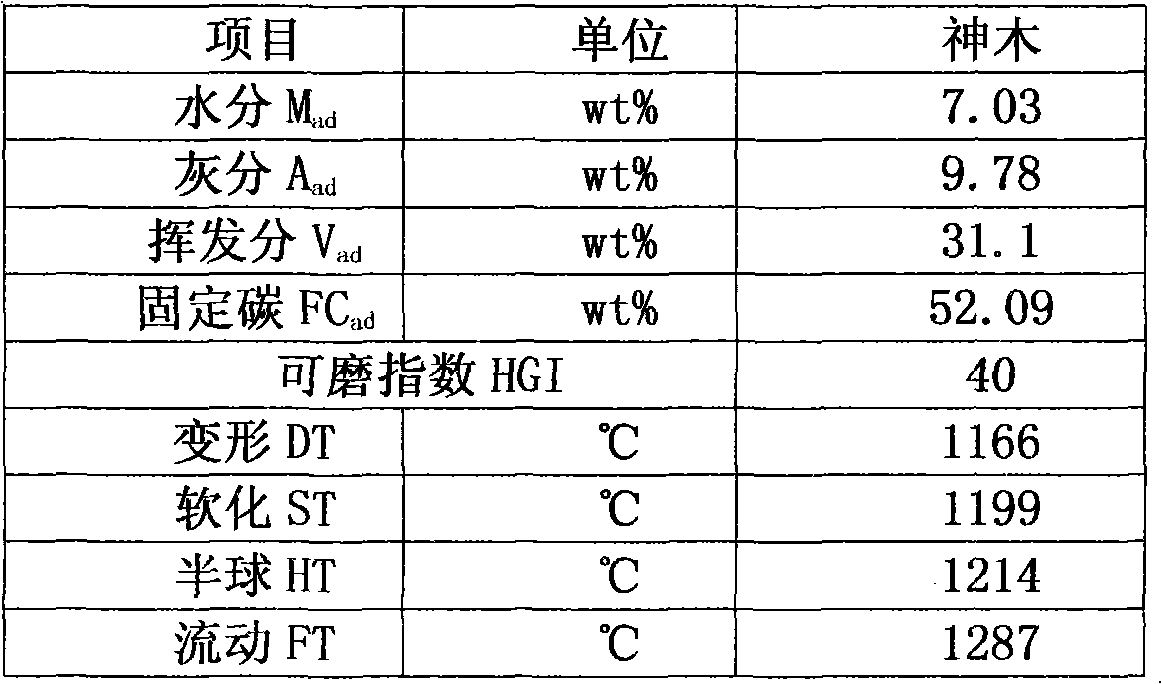

[0061] Coal sample source: Shaanxi Shenmu Coal

[0062] The coal quality analysis is as follows:

[0063]

[0064] (1) Preparation of solid powder additives: Weigh anionic dispersant sodium lignosulfonate, anionic dispersant naphthalenesulfonic acid formaldehyde condensate, nonionic dispersant Agent ethylene oxide and propylene oxide block copolymer, sodium carbonate, sodium hydroxide, mixed evenly;

[0065] (2) Preparation of coal powder: crush the Shenmu coal to a certain particle size (≤3mm), and then dry crush it with a high-speed universal crusher. Control the crushing time and directly crush to produce coal powder with a suitable particle size distribution. The particle size distribution of coal powder is:

[0066] ≥40 mesh 2.8%

[0067] 40 mesh to 80 mesh 15.6%

[0068] 80 mesh to 120 mesh 24.8%

[0069] 120 mesh to 200 mesh 12.6%

[0070] 200 mesh to 325 mesh 22.2%

[0071] ≤325 mesh 22.0%

[0072] ...

Embodiment 2

[0076] Coal sample source: Yankuang Beisu Coal

[0077] The coal quality analysis is as follows:

[0078]

[0079] (1) Preparation of solid powder additives: Weigh anionic dispersant sodium lignosulfonate, anionic naphthalenesulfonic acid formaldehyde condensate, nonionic dispersant ring Ethylene oxide and propylene oxide block copolymer, potassium carbonate, potassium hydroxide, mixed evenly;

[0080] (2) Preparation of coal powder: crush Beisu coal to a certain particle size (≤3mm), and then dry crush it with a high-speed universal crusher. Control the crushing time and directly crush to produce coal powder with a suitable particle size distribution. The particle size distribution of coal powder is:

[0081] ≥40 mesh 2.1%

[0082] 40 mesh to 80 mesh 12.9%

[0083] 80 mesh to 120 mesh 17.2%

[0084] 120 mesh to 200 mesh 9.7%

[0085] 200 mesh to 325 mesh 20.3%

[0086] ≤325 mesh 37.8%

[0087] (3) Preparation o...

Embodiment 3

[0091] Coal sample source: Guizhou Kaiyang Coal

[0092] The coal quality analysis is as follows:

[0093]

[0094] (1) Prepare solid powder additives: weigh anionic dispersant calcium lignosulfonate, anionic dispersant naphthalenesulfonic acid formaldehyde condensate, nonionic dispersant Agent ethylene oxide and propylene oxide block copolymer, ammonium carbonate, sodium hydroxide, mixed evenly;

[0095] (2) Preparation of coal powder: crush Kaiyang coal to a certain particle size (≤3mm), and then dry crush it with a high-speed universal crusher. Control the crushing time and directly crush to produce coal powder with a suitable particle size distribution. The particle size distribution of coal powder is:

[0096] ≥40 mesh 3.9%

[0097] 40 mesh to 80 mesh 12.4%

[0098] 80 mesh ~ 120 mesh 10.0%

[0099] 120 mesh to 200 mesh 16.9%

[0100] 200 mesh to 325 mesh 37.6%

[0101] ≤325 mesh 19.2%

[0102] (3) Pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com